Aluminum alloy temper (commonly known as artificial aging or stabilization treatment) is a process that involves heating the alloy to a certain temperature and holding it at that temperature for a period of time after solution treatment, followed by cooling. Its main purposes are: Precipitation of strengthening phases: Allowing solute atoms (such as Cu, Mg,[…]

The correspondence between China aluminum rod standards and international standards is mainly reflected in two aspects: product standards and grade systems. China Core Aluminum Rod Product Standards Standard Type Core Standard Production Process Scope of Application Remarks National Standard (GB/T) GB/T 3191-2019 Extrusion Round, square, hexagonal, and other extruded bars The current latest version, replacing[…]

Aluminum alloys, as an important material in industrial and construction fields, require various processing methods. Among these, cutting is the most basic and crucial step. Depending on the application scenario and precision requirements, aluminum alloy cutting methods mainly fall into three categories: mechanical cutting, thermal cutting, and special cutting. About Us Shandong Hesheng Taifu Aluminum[…]

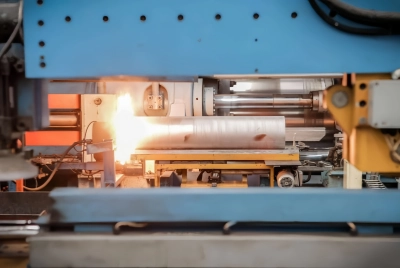

Aluminum extrusion is a plastic forming process in which aluminum alloy material undergoes heating to a ductile state and then undergoes forcing through a die of a specific shape under high pressure to form a profile with a specific cross-sectional shape. Aluminum extrusion process finds wide use in construction, transportation, electronics, aerospace and other fields,[…]

Both 5052 and 5083 belong to the 5-series Al-Mg marine-grade rust-resistant aluminum alloy, and both rely on a dense Al₂O₃ oxide film on their surface to achieve excellent corrosion resistance. However, due to differences in their chemical composition and microstructure, they have different emphases in corrosion resistance, mechanical properties, and machinability. Both belong to the[…]

ASTM and EN are the most important international certification and standard systems for aluminum bar, serving as crucial bases for international trade. They signify that aluminum bar products undergo rigorous control from raw materials and production processes to quality control and final inspection, and are accompanied by corresponding material certificates (MTC, Mill Test Certificate) to[…]

Cold-finished (CF) aluminum alloy bar refer to aluminum and aluminum alloy round or square bars formed by plastic deformation at room temperature (below their recrystallization temperature) through processes such as cold drawing, cold stretching, or precision drawing. They are typically based on extruded or rolled blanks and undergo secondary processing to achieve excellent dimensional accuracy,[…]

Both 6061 and 6082 are heat-treatable aluminum alloy from the 6000 series, offering good strength, excellent corrosion resistance, and outstanding machinability. They are widely used in structural engineering, machinery manufacturing, transportation, marine, and construction industries. Compared to 6061 aluminum, 6082 has higher mechanical strength, especially in the T6 temper, making it ideal for structural components[…]

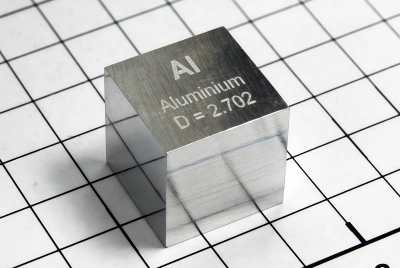

Quickly locate your desired Aluminum alloy density : press Ctrl + F and enter the grade number. Important Notice: All density values are rounded to three significant digits. Sources include the Aluminum Association (AA) standards, and other verified materials databases. Aluminum Alloy Density Chart Alloy Density (g/cm³) Density (lbm/in³) 1035 2.71 0.098 1050 2.71 0.098 1060[…]

- 1

- 2