Aluminum extrusion is a plastic forming process in which aluminum alloy material undergoes heating to a ductile state and then undergoes forcing through a die of a specific shape under high pressure to form a profile with a specific cross-sectional shape. Aluminum extrusion process finds wide use in construction, transportation, electronics, aerospace and other fields, and is one of the key technologies in modern industrial manufacturing.

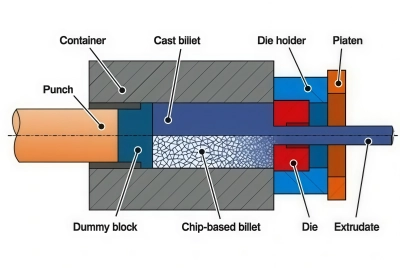

The core principle of aluminum extrusion is similar to squeezing toothpaste. An aluminum ingot heated to 400-500℃ is placed into the ingot cylinder of an extruder. A high-powered hydraulic system applies pressure, reaching thousands of tons, pushing the extrusion rod to plastically deform the ingot, forcing it out through the precision forming orifice of the die to form the desired cross-sectional shape and size. Under pressure, the die divides the aluminum ingot into several streams of metal, which flow through a diversion orifice into the welding chamber, where the chamber re-welds them under high temperature, high pressure, and high vacuum conditions. Finally, it flows out through the gap between the die core and the die orifice, forming the required tubular or hollow profile.

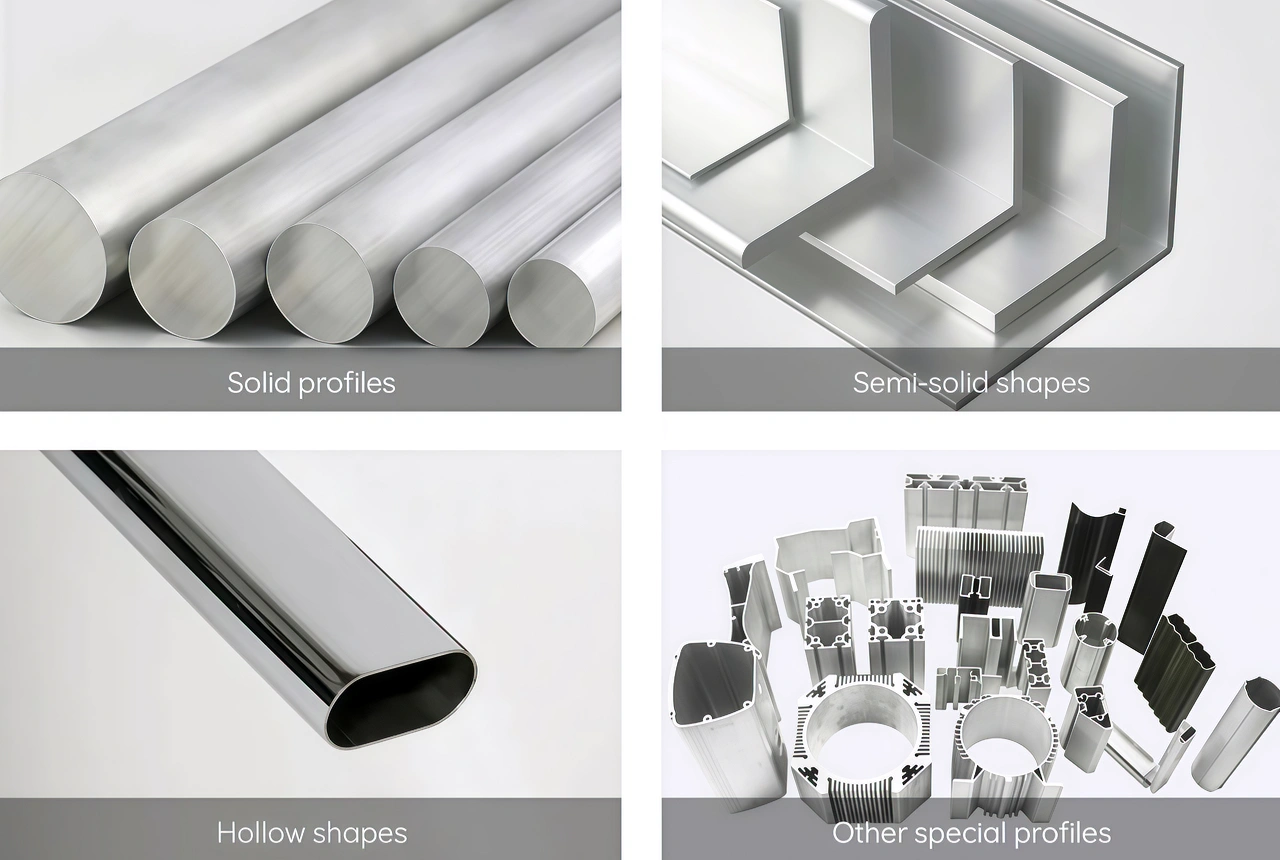

What Shapes Can Extrusion Produce?

Extrusion is part of many industries, so it’s impossible to provide a complete list of all its types. There are infinite possibilities for extruded shapes, with various configurations and sizes available. The main categories include:

- Solid profiles: solid bars and rods with various cross-sections (such as circular, rectangular, square, etc.).

- Semi-solid shapes: for example, angles, channels, and other partially open shapes.

- Hollow shapes: tubes or profiles with various cross-sections (for example, circular, rectangular, square, etc.).

- Other special profiles: unique shapes customized according to specific application needs. These profiles often have complex cross-sections and special functions to meet specific design and engineering requirements.

Classification of Extrusion Processes

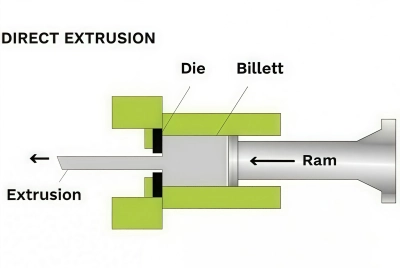

Direct Extrusion

Direct aluminum extrusion, or forward extrusion, is the most common method. The process pushes heated aluminum billets through a fixed die, shaping the aluminum as it passes through.

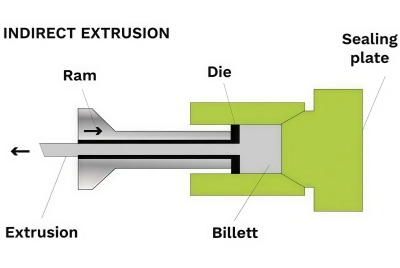

Indirect Extrusion

Indirect aluminum extrusion, or backward extrusion, uses a stationary billet and a moving die. A hollow ram pushes the die towards the billet, reducing friction and energy use.

Hot, Warm and Cold Extrusion

Hot above recrystallization, warm between room temperature and recrystallization, and cold at room temperature. The hot minimizes tool wear, while warm and cold boost material strength, but may shorten die life.

Process Flow

1. Billet Preparation and Heating

Based on high-quality aluminum ingots, the process adds alloying elements such as silicon and magnesium. It then smelts, refines, and casts the billets to produce uniform specifications. The process heats the aluminum rods to 400-500℃ to optimize their plasticity. Simultaneously, it preheats the die to 480℃ to reduce thermal shock and ensure uniform metal flow and forming stability.

2. Extrusion Molding

Under the high pressure of a large extruder (pressure range from 100 tons to 15,000 tons), the extrusion process plastically deforms the aluminum billets through the die orifice, continuously extrudes them to form profiles consistent with the die shape. The process adjusts the extrusion speed according to the alloy and die shape, ranging from 1-2 feet per minute to 180 feet per minute. The extrusion ratio (the ratio of the aluminum rod cross-sectional area to the profile cross-sectional area) can reach 500, and a single extrusion can produce products up to 200 feet long.

3. Quenching Treatment

The process rapidly cools the extruded profile (air cooling or water mist cooling) from 520℃ to 60℃, achieving solid solution strengthening, laying the foundation for the profile’s mechanical properties, and preventing grain coarsening.

4. Traction Straightening

The straightening process clamps and draws out the profile at a uniform speed using a traction machine, effectively preventing twisting, bending, and other deformations, ensuring the straightness and geometric stability of the profile. The cutting process then cuts the straightened profile to length.

5. Aging Treatment

The aging process places the cut profile in an aging furnace for heat treatment. After reaching an aging temperature of 200℃, it holds the profile for 2-6 hours to further improve its hardness, strength, and comprehensive mechanical properties, meeting standard requirements. After aging, it allows the profile to cool naturally or using a cold air blower.

6. Surface Treatment

Through processes such as anodizing, electrophoresis, and powder coating, these techniques enhance the profile’s corrosion resistance, wear resistance, and aesthetics, expanding its application range. Anodizing can form a 25-micron oxide film, which enhances both corrosion resistance and surface finish.

Advantage of Extruded Aluminum Alloys

| Advantage | Explanation |

| Lightweight and High-Strength | Aluminum is more than 33% lighter than steel while retaining most of its strength. Most aluminum alloys have a tensile strength ranging from 70 to 700 MPa and a density two-thirds less than steel, making them ideal materials for automotive lightweighting and aerospace applications. |

| Good Corrosion Resistance | Aluminum naturally forms a protective aluminum oxide film on its surface, which is further enhanced by anodizing. It can undergo 25-micron anodizing treatment in outdoor environments. |

| High Design Flexibility | Virtually any cross-sectional shape can be extruded from aluminum, ranging from ultra-large tubes and profiles with outer diameters of 500-1000 mm to ultra-small precision profiles with cross-sectional dimensions as small as a matchstick. |

| Excellent Thermal Conductivity | Aluminum has thermal conductivity similar to copper but is much lighter, making it an excellent heat conductor widely used in heat sinks, electronic device housings, and other applications. |

| Easy to Manufacture and Assemble | The design of aluminum extrusions can simplify subsequent manufacturing and assembly, accommodating a variety of manufacturing processes. |

| Sustainable | Aluminum can be recycled indefinitely without losing its properties. The extrusion process often produces aluminum extrusions from high-recycled content material, and their lightweight, strength, and design flexibility offer environmental benefits in use. |

| Seamless | Aluminum profiles can achieve complex shapes without mechanical connections, making them stronger than similar components and reducing the risk of loosening or leaking. |

| Flexible | Aluminum combines strength with flexibility, able to bend or spring back under load, making it useful in automotive crash management systems. |

Application of Extruded Aluminum Alloys

Aluminum extrusions have consistently demonstrated their excellent performance, reliability, and efficiency in various markets, ranging from durable consumer goods to transportation, electronics, and building and construction.

| Application | Explanation |

| Construction | Aluminum is a preferred material for modern buildings, used in door and window frames, curtain walls, railings, ceilings, and other architectural decorations due to its corrosion resistance and aesthetic appeal. |

| Transportation | Aluminum is used in automobile body frames, bumpers, chassis components, high-speed rail train structural components, aircraft fuselages, and wings to achieve vehicle lightweighting and improve fuel efficiency or driving range. |

| Electronics and Appliances | Aluminum is used in radiators, housings, panels, and LED light fixture housings to quickly dissipate heat from equipment due to its excellent thermal conductivity. |

| Aerospace | Aluminum is used in aircraft structural components, brackets, and interior trim components to ensure flight performance due to its high strength-to-weight ratio and corrosion resistance. |

| New Energy | Aluminum is used in solar panel frames and support systems, wind turbine components, and battery trays to provide stable and durable support structures. |

Commonly Extruded Aluminum Alloys

6061 Aluminium

With excellent overall performance, it finds common use in automobile, shipbuilding, and machinery manufacturing industries.

6063 Aluminium

The most commonly used building profile alloy has good extrudability and finds wide use in doors, windows, curtain walls, etc.

6082 Aluminium

High-strength alloys have good overall performance and are suitable for structural components that require high strength.

7005 Aluminium

It has good weldability and high strength, and finds main use for welding structural parts, such as bicycle frames and car bumpers.

7075 Aluminium

Ultra-high strength alloys find main use in aerospace, military and other fields where extremely high strength is required.

2024 Aluminium

High strength but poor corrosion resistance and requires surface treatment. It finds main use in the aerospace field.

When selecting aluminum extrusion grades, the selection process must comprehensively consider factors such as product strength requirements, corrosion resistance, extrudability, surface treatment properties, and cost. HSTF offers a comprehensive selection of aluminum alloys.

About Us

Shandong Hesheng Taifu Aluminum Group Co., Ltd. is a leading extruded aluminum producer and supplier in China. It has earned the recognition as a “China Integrity Enterprise” for many consecutive years. We specialize in the production, processing, and trading of aluminum rods. With over 18 years of experience in the aluminum industry, we can provide a full range of high-quality extruded aluminum alloys at competitive prices.