Aluminum alloys, as an important material in industrial and construction fields, require various processing methods. Among these, cutting is the most basic and crucial step. Depending on the application scenario and precision requirements, aluminum alloy cutting methods mainly fall into three categories: mechanical cutting, thermal cutting, and special cutting.

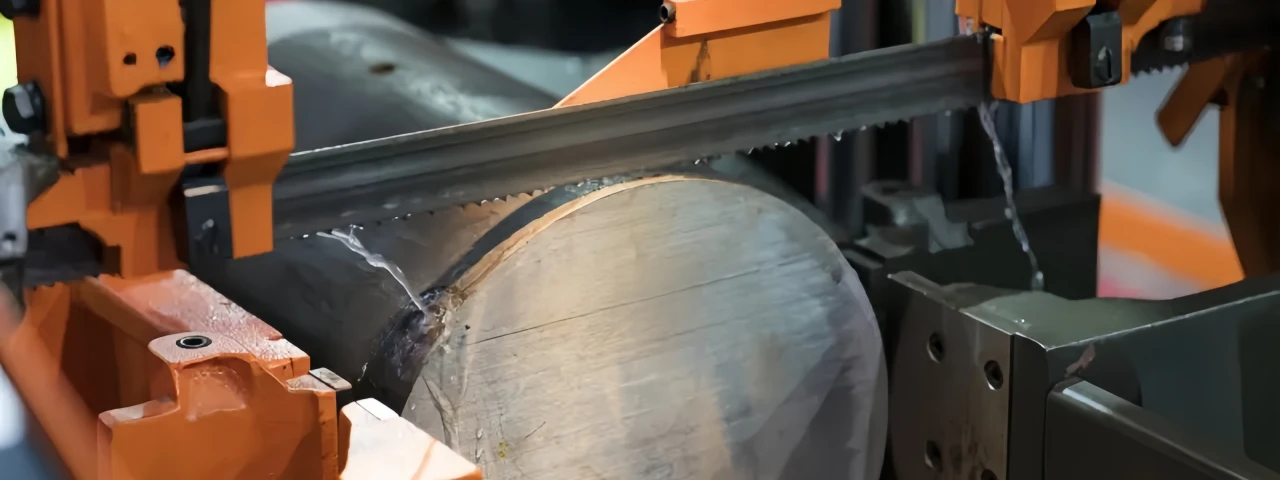

Mechanical sawing uses magnetic drills or aluminum saws with cutting blades, which is more efficient and accurate than hand sawing. Saws can be categorized by type:

| Type | Explanation |

| Circular saw | Equipped with a toothed rotating blade, suitable for straight cutting of aluminum sheets. |

| Band saw | Uses a continuous toothed metal band, suitable for curved and irregular cuts. |

| Beveling saw | Can cut at various angles, suitable for framing and model making. |

| Chopper saw | Uses a downward cutting motion, suitable for thicker aluminum sections. |

- Mechanical sawing has the advantages of simple equipment, affordability, and convenient operation, but the cut edges are relatively rough and usually require subsequent finishing.

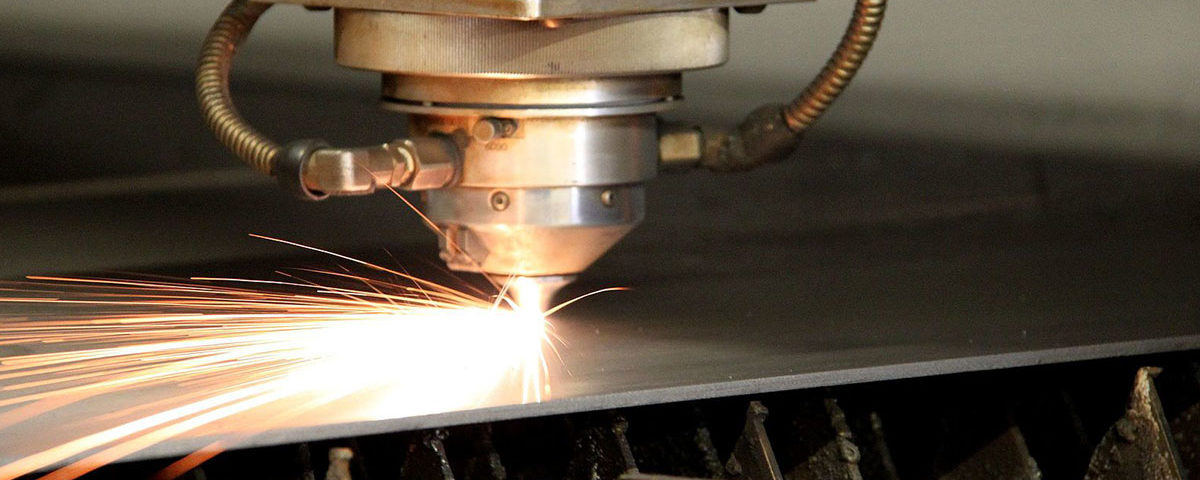

1. Laser Cutting Aluminum

Laser cutting utilizes a high-energy laser beam to precisely cut aluminum alloys, and is one of the most advanced cutting technologies currently available.

Working Principle: The aluminum plate is placed on the laser cutting table. Parameters such as laser power, speed, and focus are adjusted according to the thickness and type of aluminum. The laser beam irradiates the aluminum surface along a preset path, rapidly melting and removing the metal, achieving a clean and precise cut.

Technical Advantages:

- High Precision: Achieves millimeter-level precision, suitable for complex shapes and intricate designs.

- High Speed: Faster than traditional cutting methods, especially suitable for small to medium-sized production batches.

- Non-Contact Processing: No mechanical stress is generated, resulting in a smooth, burr-free cut surface.

- High Flexibility: Allows for quick switching between different cutting designs and material types.

2. Plasma Cutting Aluminum

Plasma cutting of aluminum utilizes a high-temperature plasma arc as a heat source. A high-speed plasma stream melts the metal and disperses the molten material to form a cut.

Working Principle: The plasma cutting torch generates a high-speed jet of ionized gas from the nozzle, conducting current to the workpiece. As the plasma heats the workpiece, it melts the aluminum along a predetermined cutting line. The high-speed plasma and compressed gas disperse the molten metal to form the cut.

Technical Advantages:

- High Cutting Speed: Especially effective when cutting aluminum materials 1/2 inch thick or thinner.

- Versatility: Capable of cutting aluminum materials of various thicknesses and shapes, including painted or rusted surfaces.

- Portability: The system is typically portable and suitable for working in various locations.

- Cost-Effectiveness: Cheaper than laser cutting machines, with lower initial investment and operating costs.

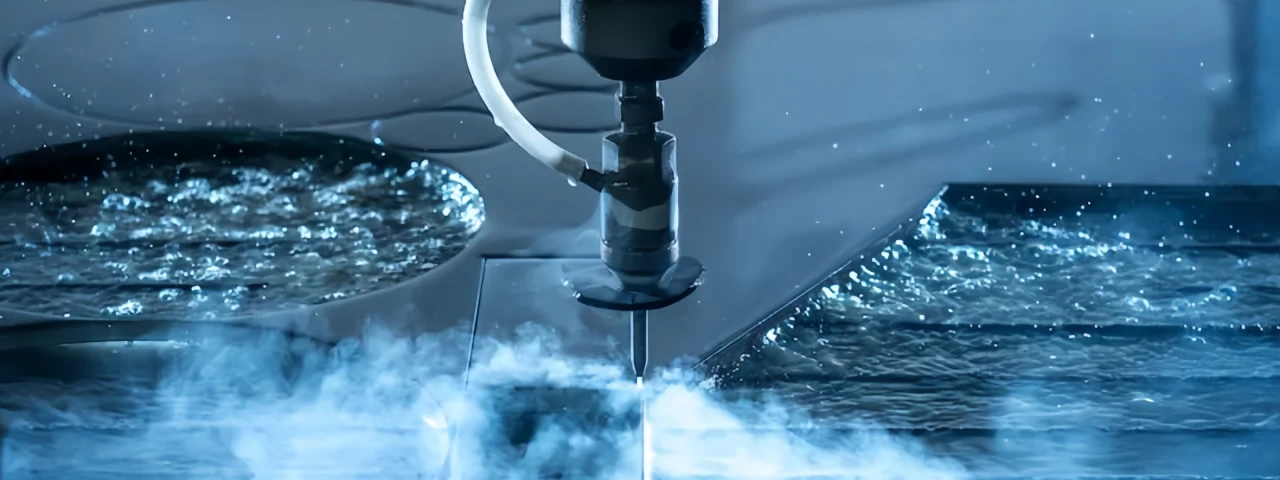

1. Waterjet Cutting Aluminum

Waterjet cutting utilizes a high-pressure water jet (usually mixed with abrasive materials such as garnet) for cutting, and is a cold-working method.

Working Principle: Ordinary water is pressurized to 3000 bar (approximately 60000 PSI) by an ultra-high-pressure pressurizer, and then a water jet with approximately three times the speed of sound is generated through a 0.3mm diameter nozzle. Under computer control, it cuts any shape.

Technical Advantages:

- No Heat-Affected Zone: The cold cutting process prevents changes in the microstructure of aluminum and eliminates thermal deformation.

- High Precision: Enables complex cuts and fine details with excellent edge quality.

- Material Preservation: The material does not harden or deform, maintaining the integrity of the aluminum.

- Environmentally Friendly and Safe: No harmful gases are produced; water and abrasives are recyclable.

Applications: Can cut various thicknesses (from thin paper to hundreds of millimeters thick), especially suitable for medium-thickness aluminum alloy sheets of 4-20mm, offering significant advantages in efficiency and cost.

2. Wire EDM

Wire EDM (Electrical Discharge Machining) utilizes the principle of electrical discharge machining, making it particularly suitable for precision machining of high-hardness aluminum alloys.

Working Principle: A pulsed discharge is generated between the electrode wire and the workpiece, removing material through electro-erosion. This electrical discharge machining process does not rely on mechanical force, and the workpiece will not deform due to cutting forces.

Technical Advantages:

- No Mechanical Stress: Suitable for thin-walled or slender high-hardness aluminum alloy parts.

- Good Surface Quality: Uniform surface texture can be obtained by optimizing electrical parameters.

- High Hardness Adaptability: Machining efficiency is independent of material hardness; stable cutting is possible even after heat treatment.

Comparison of Cutting Methods

|

Cutting Method |

Precision | Speed | Cost | Suitable Thickness | Surface Quality |

Thermal Effect |

|

Hand Sawing |

Low | Slow | Low | Thin plates | Rough | None |

| Mechanical Sawing | Medium | Medium | M edium | Medium-thick plates | Relatively rough |

None |

|

Laser Cutting |

High | Fast | High | Thin plates | Smooth | Small |

| Plasma Cutting | Medium | Fast | Medium | Thick plates | Average |

Large |

|

Waterjet Cutting |

High | Medium | High | Full range | Smooth | None |

| Wire EDM Cutting | Very High | Slow | High | Thin plates | Very smooth |

Very Small |

Selection Suggestions:

- Small batch, simple cutting: Hand sawing or mechanical sawing

- Large batch production: Laser cutting or plasma cutting

- High precision requirements: Laser cutting or wire EDM cutting

- Thick plate cutting: Plasma cutting or waterjet cutting

- No heat-affected zone requirements: Waterjet cutting or wire EDM cutting

About Us

Shandong Hesheng Taifu Aluminum Group Co., Ltd. is a leading aluminum producer and supplier in China. It has earned the recognition as a “China Integrity Enterprise” for many consecutive years. We specialize in the production, processing, and trading of aluminum alloy. With over 18 years of experience in the aluminum industry, we can provide a full range of high-quality aluminum alloys at competitive prices.

More About Us