Both 5052 and 5083 belong to the 5-series Al-Mg marine-grade rust-resistant aluminum alloy, and both rely on a dense Al₂O₃ oxide film on their surface to achieve excellent corrosion resistance. However, due to differences in their chemical composition and microstructure, they have different emphases in corrosion resistance, mechanical properties, and machinability.

Both belong to the 5xxx series Al-Mg marine-grade rust-resistant aluminum alloy. Their corrosion resistance mainly stems from the natural formation of a dense, strongly adhering Al₂O₃ oxide film on their surface, effectively resisting erosion from the atmosphere, fresh water, and various chemical media. Surface treatments such as anodizing or painting can further enhance their protective capabilities.

|

Aspect |

5052 Aluminum Alloy |

5083 Aluminum Alloy |

| Core Positioning | Medium strength, high formability, general-purpose rust-resistant aluminum | High strength, superior corrosion resistance, welding-friendly structural aluminum |

| Typical Composition | Mg: 2.2–2.8% Cr: 0.15–0.35% |

Mg: 4.0–4.9% Mn: 0.40–1.0% |

| Resistance to Seawater Corrosion | Good, but slightly inferior to 5083 | Better – one of the top choices for marine applications |

| Stress Corrosion Cracking (SCC) | Not prone to occur | Requires attention – risk increases under high temperature or stress |

| Strength Level | Medium (Tensile strength: 170–305 MPa) | Higher (Tensile strength ≥ 270 MPa) |

| Formability & Weldability | Excellent formability, good weldability | Moderate formability, but high joint strength after welding |

| Typical Applications | Fuel tanks, architectural decoration, automotive body panels, electrical enclosures | Ships, offshore platforms, pressure vessels, rail vehicles |

Differences Between 5052 and 5083

1. Resistance to Seawater / High-Chloride Environments

- Marine 5083 Aluminum Alloy: The higher magnesium content (4.0–4.9%) enables formation of a more stable passive film in seawater, giving better resistance to pitting and erosion corrosion. Its corrosion rate can be as low as 0.01–0.03 mm/year, making it a preferred material for ships, offshore platforms, and other harsh environments.

- Marine 5052 Aluminum Alloy: Offers good seawater resistance but is generally inferior to 5083, suitable for sea wind exposure or light splash zones.

2.Stress Corrosion Cracking (SCC)

- Marine 5052 Aluminum Alloy: Contains chromium and moderate Mg content, making it insensitive to SCC, so this issue rarely needs special consideration in engineering applications.

- Marine 5083 Aluminum Alloy: The high Mg content makes it susceptible to SCC when exposed to temperatures above ~65 °C combined with tensile stress. Therefore, in high-temperature service or highly stressed welded structures, precautions are necessary—e.g., using appropriate tempers (such as H116/H321) or performing stress-relief heat treatment.

3.Effect of Material Temper

- For both alloys, corrosion resistance follows the same trend: Annealed (O temper) > Cold-worked (H temper) > Welding Heat-Affected Zone (HAZ). Cold working introduces internal stresses, while the HAZ experiences microstructural changes that reduce corrosion resistance, requiring focused protective measures in structural parts.

Surface Treatment Improves Corrosion Resistance

Chemical/Electrochemical Conversion Films

These treatments provide an excellent substrate for subsequent coatings and also offer some protection.

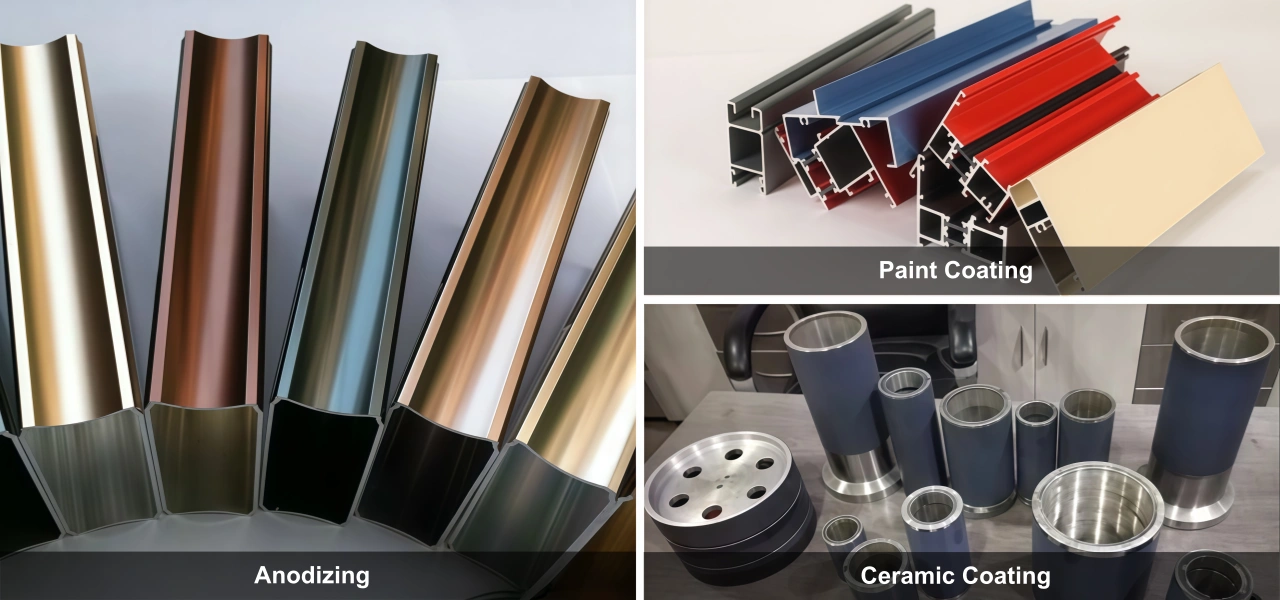

- Anodizing: Forms a thick, dense Al₂O₃ film in electrolytes such as sulfuric acid, significantly improving corrosion and abrasion resistance. Sealing can further enhance the protective effect.

- Chemical Conversion Films: Such as chromates, phosphochromates, and environmentally friendly rare-earth conversion films. They form a thin, uniform passivation layer on the surface, enhancing corrosion resistance and serving as excellent undercoating layers.

High-Performance Coating System

This is the most mainstream engineering solution for marine environments.

- Primer: A specialized aluminum primer (such as zinc chromate primer) free of heavy metal ions is selected to promote oxide film growth and enhance adhesion.

- Intermediate/Topcoat: Thick-film epoxy, polyurethane, or fluorocarbon topcoats are used to form a physical barrier, blocking chloride ions and moisture.

- Compatible System: The location selects coatings with appropriate electrical resistance, alkali resistance, and antifouling properties (bottom, waterline, deck, etc.).

Advanced Ceramic Coatings

Suitable for high-strength structural components such as 5083 alloys, simultaneously improving wear resistance and corrosion resistance.

- Micro-arc Oxidation (MAO): In-situ growth of a ceramic oxide film on the aluminum alloy surface. Through process optimization (such as adding nano-TiO₂), nano-TiO₂ can make the film denser, improving corrosion resistance by 1-2 orders of magnitude.

- PVD/CVD Hard Coatings: Such as CrN, TiN, etc., significantly reducing corrosion current density and contact resistance, suitable for applications with special requirements.

Material Selection Guidelines

Scenarios where 5083 is preferred:

- Environment: Harsh marine environments such as long-term immersion in seawater, high salt spray, and strong splash zones.

- Structure: Requires high-strength welded structures, such as ship hulls, offshore platform supports, seawater desalination equipment, and pressure vessels.

Scenarios where 5052 is preferred:

- Environment: General atmospheric conditions, humid air, fresh water, or environments with mild chemical media.

- Process: Requires high formability, such as complex sheet metal parts, fuel tanks, architectural decorative parts, and electrical enclosures.

About Us

Shandong Hesheng Taifu Aluminum Group Co., Ltd. is a leading aluminum producer and supplier in China. And has been recognized as a “China Integrity Enterprise” for many consecutive years. We specialize in the production, processing, and trading of aluminum rods. With over 18 years of experience in the aluminum industry, we can provide a full range of high-quality aluminum at competitive prices.