Professional Supplier

Focus on aluminum bar

Aluminum alloys find wide use in sports equipment, primarily due to their lightweight, high strength, excellent corrosion resistance, and superior machinability. In equipment such as bicycles, tennis rackets, badminton rackets, trekking poles, and skis, aluminum alloys undergo processing through extrusion and forging to create tubes, profiles, and components, effectively reducing equipment weight and improving athletic performance.

Compared to traditional steel, aluminum alloy equipment is lighter and more durable. Its surface can be anodized to achieve a variety of colors and improved wear resistance. Furthermore, it is more economical than high-end materials like carbon fiber, making it a crucial material choice in sports equipment manufacturing.

Commonly used aluminum alloys include 2024, 2A12, 5086 , 5052, 6061, 6063, 7001, 7005 and 7075. These alloys play an important role in the manufacturing of sports gear, providing athletes with better equipment options.

Feature |

Description |

| Lightweight | Aluminum alloy is a lightweight material, making sports equipment easier to carry and handle, reducing the burden on athletes, and enhancing comfort and flexibility during sports activities. |

| High Strength | Aluminum alloy has excellent strength to withstand compressive, tensile, and other forces during sports, ensuring the structural stability and safety of sports equipment. |

| Good Corrosion Resistance | Aluminum alloy exhibits good corrosion resistance, making it resistant to rust or corrosion when exposed to humid environments or sweat, maintaining the appearance and performance of sports equipment. |

| Excellent Wear Resistance | Proper surface treatment enhances the wear resistance of aluminum alloy, reducing frictional wear and preserving the appearance and performance of sports equipment over time. |

| Good Machinability | Aluminum alloy is easy to process and shape, allowing for the manufacture of various shapes and sizes of sports equipment to meet the requirements of different sports. |

| Surface | Smooth and aesthetically pleasing surface enhances the appearance of sports equipment, providing users with a more enjoyable experience. |

| Components | Description |

| Frame | The most important component in bicycles where aluminum alloy is used. 6061 aluminum alloy, due to its good strength and machinability, finds wide use in mid-to-low-end bicycle frames; while 7075 aluminum alloy, with even higher strength, finds frequent use in high-end mountain bikes and road bikes. Aluminum alloy frames can reduce weight by more than 20% compared to steel frames while maintaining high structural strength. |

| Front Fork | Made of aluminum alloy, it features lighter weight and good rigidity, improving riding responsiveness. |

| Handlebars | Made of 6061 aluminum alloy, lightweight and high-strength, providing excellent handling. |

| Steering Rod and Stem | Made of 2024, 6061, or other aluminum alloys, formed through hot extrusion. |

| Wheel Rims | Another important area of application for aluminum alloys. Aluminum alloys such as 6061, 6063, 6N01, and 7003 are widely used in wheel rim manufacturing. Aluminum alloy wheels have a lighter weight and good strength, which can improve riding speed and stability. |

| Gear Crank | Made of 2014, 2017, and 6061 aluminum alloy, precision forged and CNC machined to reduce friction loss and improve transmission efficiency. |

| Pedals | Made of AC4C aluminum alloy, manufactured through forging to achieve lightweight while ensuring pedaling rigidity. |

| Brakes | Made of 6061 and 6151 aluminum alloys, they have excellent high temperature resistance and deformation resistance, and can withstand the high temperatures generated during braking. |

Aluminum alloys, known for their lightweight, high strength, and corrosion resistance, are widely used in outdoor sports equipment such as aluminum camping gear, tents, folding tables and chairs, aluminum trekking poles, and sports water bottles. These applications not only enhance the convenience and comfort of outdoor activities but also showcase the outstanding advantages of aluminum alloy materials.

| Components | Description |

| Tent Poles | Made of 7001 or 7075 aluminum alloy, these multi-section telescopic poles are cold-drawn, making them over 30% lighter than traditional fiberglass poles and less prone to breakage. The surface is anodized for excellent corrosion resistance. |

| Stove and Cookware | Made of 5052 or 3003 aluminum alloy, these have good thermal conductivity, are lightweight, and easy to carry. For example, aluminum alloy is often used for components such as the frame and wind deflector of titanium alloy stoves. |

| Folding Tables and Chairs | Made of 6061 aluminum alloy profiles, these are hinged, lightweight, strong, and compact when folded, making them suitable for outdoor camping. |

| Hiking Poles | The most typical outdoor gear using aluminum alloy. Made of 7075 or 6061 aluminum alloy tubing, they are cold-drawn into a multi-section telescopic structure, weighing only 200-300 grams, yet strong enough to support the weight of a person. The surface is anodized, forming a wear-resistant and scratch-resistant protective layer, and they are available in a variety of colors. |

| Ice Axe and Crampons | The shaft and frame are made of 6061 aluminum alloy, which greatly reduces the load while ensuring strength and improving climbing efficiency. |

| Components | Description |

| Kayak Frame | Made of 6061 aluminum alloy, manufactured through welding or riveting processes, it is lightweight, high-strength, and easy to transport and assemble. The surface is anodized, providing excellent resistance to seawater corrosion. Compared to traditional wooden or fiberglass frames, the aluminum alloy frame is more than 30% lighter and structurally more stable. |

| Kayak Paddles and Paddleboard Paddles | 7075 aluminum alloy is one of the strongest aluminum alloys. After T6 heat treatment, its tensile strength can reach 570MPa. Aluminum alloy paddles are as light as 500-800 grams, yet strong enough to withstand the huge impact of paddling, and are not easily deformed. |

| Hull Structure | Small speedboats and motorboats use 5083 or 5086 aluminum alloy for their hulls, manufactured through welding. These aluminum alloys offer excellent resistance to seawater corrosion, high strength, and light weight, reducing weight by more than 40% compared to fiberglass hulls, thus improving speed and fuel efficiency.

Aluminum alloys also find wide use in the superstructure of yachts, such as decks and bulwarks, and undergo manufacturing through extrusion or welding processes to reduce overall weight and improve stability. |

| Accessories and Accessories | Marine ladders and diving platforms use 6061 aluminum alloy, employ welding for manufacture, and undergo anodizing for corrosion resistance, high strength, and strong load-bearing capacity.

Marine masts and sails use 6061 or 7075 aluminum alloy, and utilize extrusion for lightweight, high strength, and strong wind resistance. |

| Components | Description |

| Venue Building Structure | The stadium roof utilizes a large-span aluminum alloy grid shell structure, connected by welding or bolting. It is lightweight, has a large span, and can cover large stadiums.

The grandstand roof uses aluminum alloy profiles and sheets, and employs extrusion molding and welding processes for manufacture. It is lightweight, corrosion-resistant, and has a long service life. The stadium curtain wall and skylight roof use 6063 aluminum alloy profiles, extruded and treated with anodizing or fluorocarbon coating. This provides good weather resistance and a variety of colors. |

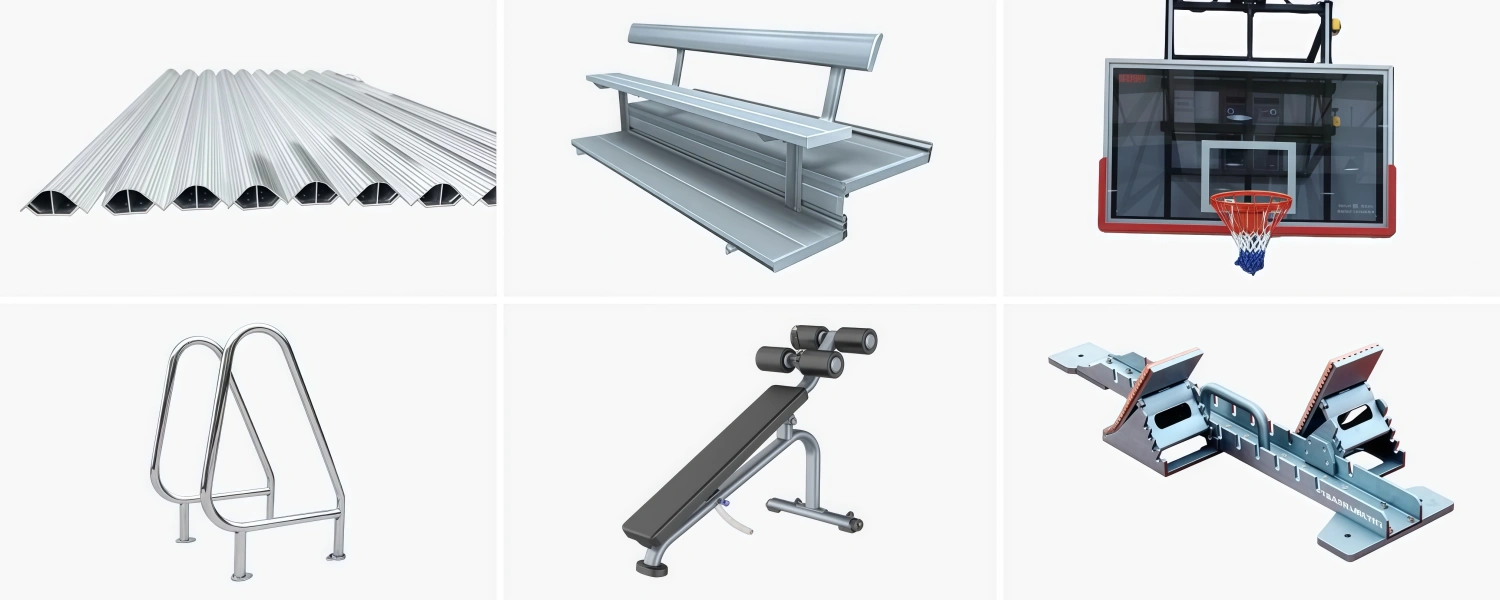

| Field Facility | The use of aluminum profiles in soccer goal frames and basketball hoop structures ensures lightweight, high strength, and easy installation and disassembly. This enhances equipment durability and safety. |

| Swimming Pool Facilities | Constructing swimming pools with aluminum involves using large extruded profiles: easy assembly, shorter construction period; aesthetically pleasing, clean and hygienic; corrosion-resistant, leak-proof, and easy to maintain. |

| Fitness Equipment | Aluminum alloys find common use in fitness equipment such as dumbbell racks, machine racks, equipment accessories, treadmill frames, and exercise bike frames.

Aluminum alloy fitness equipment often utilizes alloys like 6061, 6063, and 6005, known for their excellent extrusion performance, outstanding surface treatment characteristics, and sufficient strength to meet the demands of fitness equipment. They also boast good weldability and ease of processing and assembly. |

| Athletics Equipment | Aluminum alloys find common use in athletics equipment such as starting blocks, hurdles, and javelins.

In athletics equipment, aluminum profiles need to have high strength and good corrosion resistance, so 6061 and 7075 aluminum alloys are the common choice. Javelins often use high-strength hard aluminum alloy 2024 or ultra-high strength hard aluminum alloy 7075. |

| Components | Description |

| Ski Board | Skis are a core application area for aluminum alloys. They can undergo manufacturing using extruded or rolled aluminum alloy sheets, or die-casting from heat-treated alloys. 7075 aluminum alloy features high strength and high toughness, capable of withstanding the enormous impacts of skiing. Compared to traditional wood materials, aluminum alloy skis are lighter, stronger, and do not exhibit low-temperature brittleness, maintaining good performance even in cold environments. |

| Ski Poles | Ski poles are almost entirely made from aluminum alloy, typically using 5086 or 7075 aluminum alloy extrusion. They range in length from 1100 to 1350mm with varying wall thicknesses from 0.8mm to 1.2mm. Ski poles may appear simple, but they are actually a high-end product. |

| Accessories | Aluminum alloys are also used in accessories such as ski helmet shells, ski boot buckles, and goggle brackets. 6061 aluminum alloy finds wide use in these auxiliary components due to its good machinability and moderate strength. |

HSTF is a leading manufacturer and supplier of aluminum alloys for sports equipment in China. We specialize in the production, processing, and trading of aluminum rods. With over 18 years of experience in the aluminum industry, we can provide a full range of high-quality aluminum rods at competitive prices.