Professional Supplier

Focus on aluminum bar

Aluminum alloys offer key advantages in marine applications, including lightweight design, corrosion resistance, and high specific strength. With a density only one-third that of steel, they significantly reduce the weight of marine equipment, improving speed and fuel efficiency. Grades such as 5083 and 5086 aluminum alloys form a dense oxide film in seawater, exhibiting excellent corrosion resistance and a long service life. They also possess good weldability and machinability, making them suitable for critical components such as ship hulls, offshore platforms, and LNG storage tanks, providing lightweight, efficient, and sustainable material solutions for marine engineering.

On the other hand, the demand for aluminum alloys is also growing in emerging fields such as deep-sea oil and gas development, offshore wind power, and marine resource exploration, especially in high-tech equipment such as deep-sea equipment, marine sensors, and submersible shells.

HSTF provides a range of standard and custom aluminum products for marine and offshore projects. All our aluminum bars feature tight dimensional tolerances and excellent surface quality. We can provide Material Testing Certificates (MTC), chemical composition reports, mechanical property records, and third-party inspection certificates to meet the quality requirements of various industry applications.

Al-Mg series rust-resistant aluminum, excellent seawater corrosion resistance, good weldability, medium strength, the preferred material for ship main structures, used in critical parts such as decks and hull shells.

Al-Mg series rust-resistant aluminum alloy, medium strength, good corrosion resistance, weldability, and formability, high fatigue strength, commonly used in ship sheet metal parts, fuel tanks, conduits, and other structural components.

Al-Mg series alloy, excellent corrosion resistance and weldability, medium strength, suitable for ship decks, engine mounts, ship sides, etc., exhibiting stability in marine environments.

Al-Mg-Si series heat-treatable alloy, high strength, good corrosion resistance, and excellent weldability, used for load-bearing components such as ship fittings and mechanical structures.

Al-Mg-Si series heat-treatable alloys possess excellent corrosion resistance, weldability, and formability. This material exhibits high plasticity, good machinability, and excellent surface treatment properties, making it suitable for decorative structural components such as ship doors, windows, gangways, masts, and railings.

Al-Mg-Si series heat-treatable alloys possess high strength, excellent corrosion resistance, and superior weldability. They are suitable for load-bearing components such as high-speed ship parts and hull structures.

Al-Mg series rust-resistant aluminum alloy, with high plasticity, good formability, excellent weldability, and good seawater resistance. Used for low-load parts such as ship structural components, fuel tanks, and conduits.

Al-Zn-Mg-Cu series ultra-hard aluminum alloy, with extremely high strength but poor corrosion resistance, requiring cladding. Suitable for high-pressure structures such as special load-bearing components in ships and deep-sea equipment.

|

Alloy |

Primary Alloying Elements | Strength Level | Corrosion Resistance | Weldability |

| 5058 | Al-Mg series, with appropriately increased Ni content | Medium Strength Tensile Strength: 210-260 MPa |

Excellent resistance to pitting, crevice corrosion, and chloride stress corrosion cracking | Good |

| 5052 | Al-Mg series Mg: 2.2-2.8% |

Medium Strength Tensile Strength: 170-215 MPa |

Excellent, resistant to seawater and industrial atmospheres |

Excellent, suitable for MIG/TIG welding |

|

5A02 |

Al-Mg series Mg: 2.0-2.8% |

Medium Strength Tensile Strength: ≤147 MPa |

Excellent, suitable for marine environments | Good, excellent for resistance welding and atomic hydrogen welding |

| 5086 | Al-Mg series Mg: 3.5-4.5% |

Medium Strength Tensile Strength: ≥240 MPa |

High corrosion resistance |

Excellent, suitable for gas, arc, and resistance spot welding |

|

6061 |

Al-Mg-Si series Mg: 0.8-1.2%, Si: 0.4-0.8% |

Medium Strength Tensile Strength (T6): ≥290 MPa |

Good, no susceptibility to stress corrosion cracking | Excellent, good weldability |

| 6063 | Al-Mg-Si series Mg: 0.45-0.9%, Si: 0.2-0.6% |

Medium Strength Tensile Strength: 130-230 MPa |

Excellent, no susceptibility to stress corrosion cracking |

Excellent |

|

6082 |

Al-Mg-Si series Mg: 0.6-1.2%, Si: 0.7-1.3% |

Medium Strength Tensile Strength (T6): ≥310 MPa |

Good | Good |

| 7075 | Al-Zn-Mg-Cu series Zn: 5.1-6.1%, Cu: 1.2-2.0% |

High Strength Tensile Strength (T651): ≥560 MPa |

Fair, susceptible to stress corrosion cracking |

Poor |

HSTF offers a variety of tempering conditions. Whether you need high strength, excellent corrosion resistance, ease of machining, or specific surface treatments, we can meet your requirements.

Instant Quote

| Application | Description |

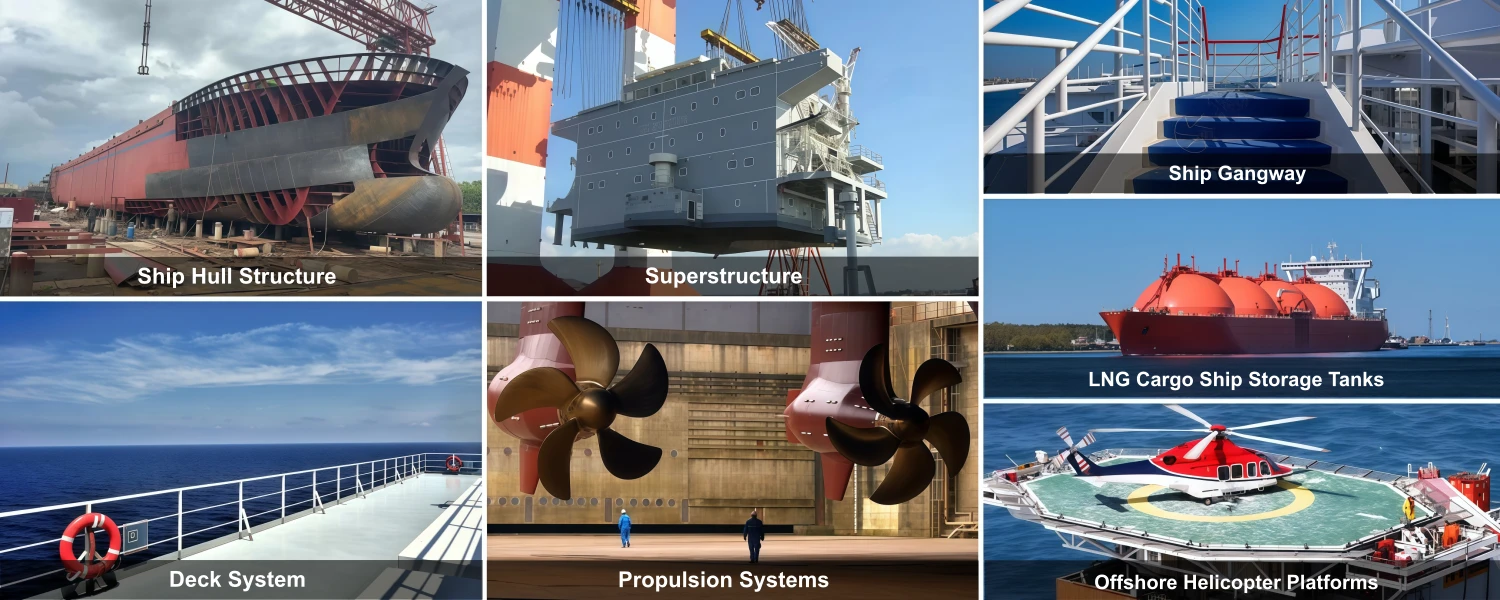

Ship Hull Structure |

The hull structure is the primary application area for marine aluminum alloys, mainly including load-bearing components such as the bottom plating, side plating, keel, and ribs. Aluminum-magnesium alloys such as 5083, 5086, and 5456 are the preferred materials for hull structures, as these alloys possess moderate strength, excellent resistance to seawater corrosion, and good weldability. Using aluminum alloys to construct hulls can reduce ship weight by 15-20%, significantly improving speed and fuel efficiency. |

Superstructure |

The superstructure includes the mast, portholes, funnels, steering room, and bulkheads. Aluminum-magnesium-silicon alloys such as 6063 and 6061 are the main materials for the superstructure, possessing good extrusion properties and corrosion resistance. In large surface ships, the entire structure above the main deck is typically made of aluminum alloys to lower the center of gravity and improve stability. |

Deck System |

The deck is a crucial load-bearing platform for a ship, and aluminum alloys such as 5454 and 5052 are the main materials used in its manufacture. Aluminum alloy decks possess a high strength-to-weight ratio, excellent corrosion resistance, and good thermal conductivity, which helps dissipate heat and improves crew comfort. On aircraft carriers, key components such as takeoff and landing decks and elevators are also made of aluminum alloys. |

Outfitting Components |

These include shipboard gangways, doors and windows, furniture, kitchen equipment, electrical control boxes, and other internal facilities. 6063 aluminum alloy profiles are widely used in the manufacture of outfitting components due to their excellent extrusion properties and surface quality. In luxury cruise ships and high-end yachts, aluminum alloy outfitting components not only meet lightweight requirements but also provide aesthetically pleasing decorative effects. |

Propulsion Systems |

Aluminum alloys are primarily used in marine propulsion systems to manufacture components such as engine housings, coolers, exhaust pipes, and propeller supports. The high strength and corrosion resistance of aluminum alloys make them ideal for manufacturing these components, while their lightweight properties help reduce the overall weight of the vessel and improve fuel efficiency. |

Specialty Vessels |

Aluminum alloys are widely used in the field of specialty vessels, including high-speed vessels such as hydrofoils, hovercraft, catamarans, and ground effect vehicles. These vessel types have extremely stringent weight requirements, where the lightweight advantages of aluminum alloys are fully utilized. High-speed vessels such as hydrofoils and hovercraft typically employ 5456-H116 or -H117 alloy welded structures, achieving speeds exceeding 40 knots. Aluminum alloys are the ideal material to meet these requirements. |

Other |

LNG cargo ship storage tanks, offshore helicopter platforms, floating bridges for ship docks and other marine engineering facilities |

We offer a range of cutting and prefabrication services, including bar cutting, extrusion, polishing, coating, drilling, grooving, bending, and edge welding preparation.

HSTF is committed to providing high-quality marine aluminum alloy materials and precision machining services to shipbuilding companies worldwide.

HSTF is a leading marine aluminium bar producer and supplier in China. We specialize in the production, processing, and trading of aluminum rods. With over 18 years of experience in the aluminum industry, we can provide a full range of high-quality aluminum rods at competitive prices.