Professional Supplier

Focus on aluminum bar

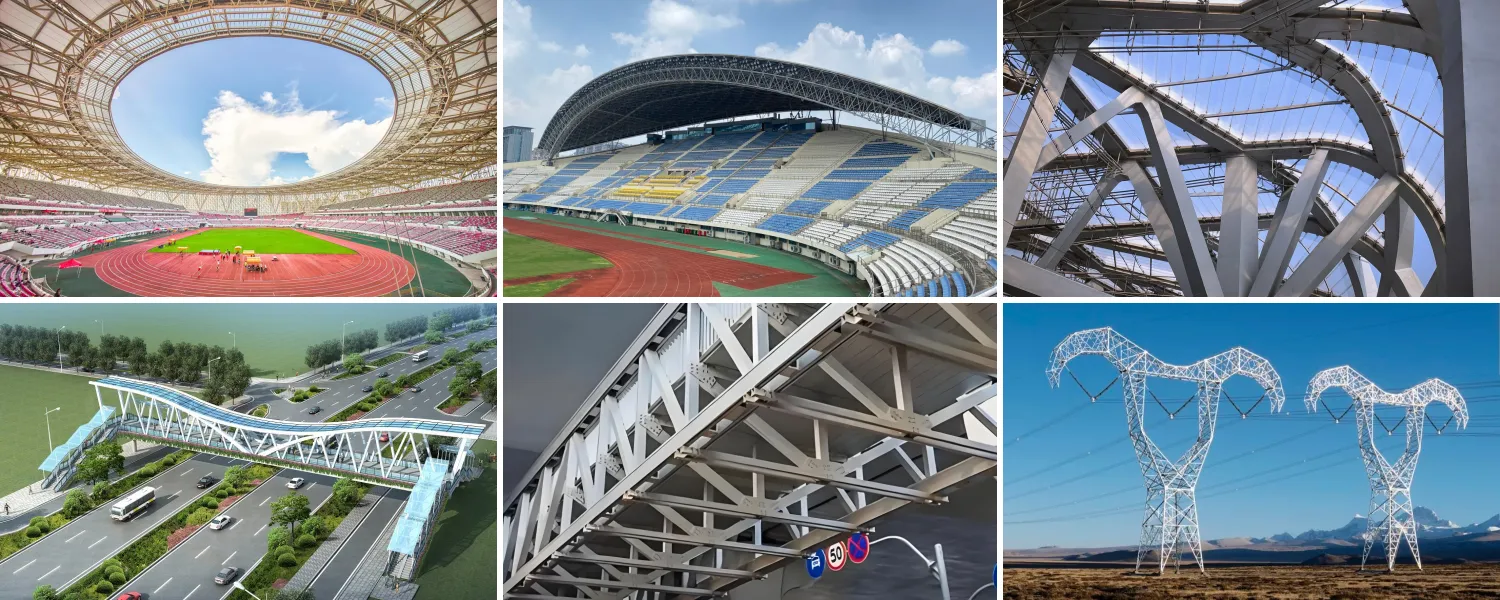

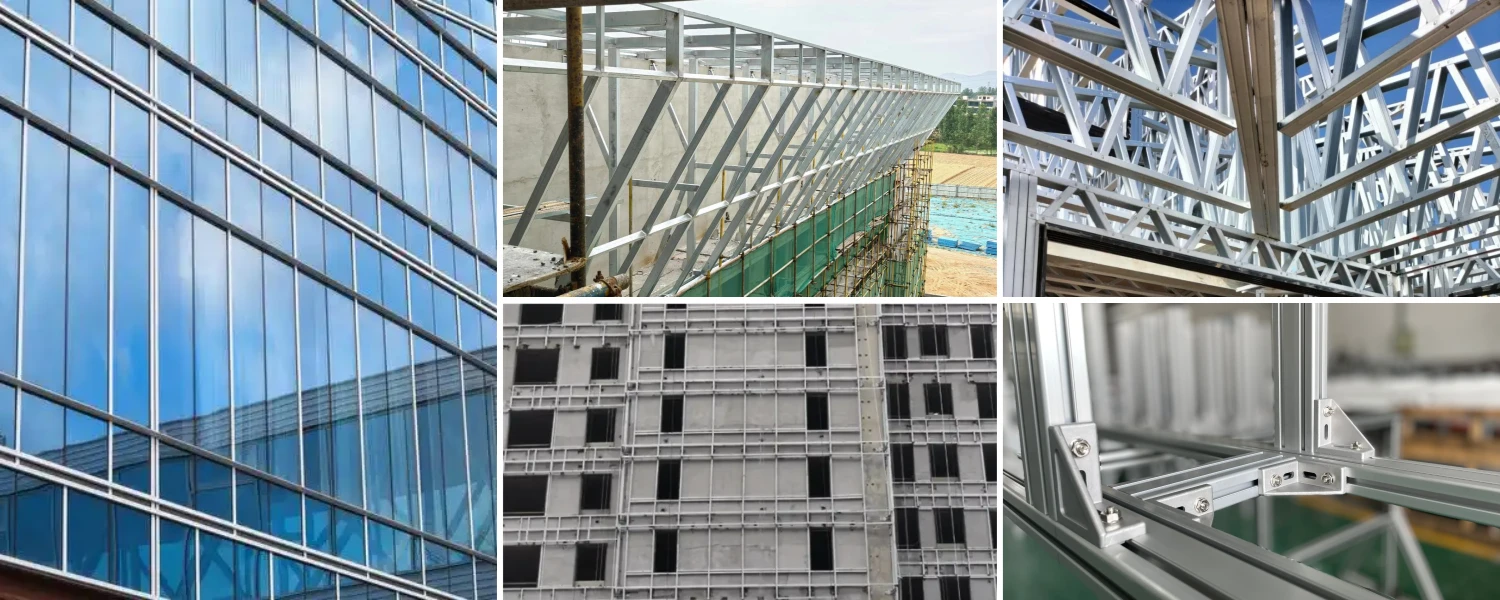

Aluminum alloys offer significant advantages in the building decoration industry, including lightweight yet high strength, corrosion resistance, ease of processing, and attractive colors. Their surfaces can undergo various treatments such as anodizing, electrophoretic coating, and fluorocarbon spraying, resulting in a rich variety of colors and textures to meet the needs of different architectural styles. They also possess excellent weather resistance and corrosion resistance, a long service life, and low maintenance costs, making them widely used in building decoration applications such as curtain walls, doors and windows, ceilings, and railings.

Aluminum alloy bars are extruded into window and door profiles, a primary material for building doors and windows. Compared to traditional materials, aluminum alloy doors and windows offer advantages such as light weight, high strength, corrosion resistance, and ease of processing. Furthermore, surface treatments like anodizing and fluorocarbon coating can achieve a rich variety of colors and textures to meet the needs of different architectural styles.

Aluminum alloy door and window profiles primarily use 6-series aluminum alloys, with 6063 and 6061 being the most commonly used grades. 6063 aluminum alloy possesses good extrudability and weldability, moderate strength, and excellent surface treatment properties, making it suitable for manufacturing main profiles such as door and window frames and sashes. 6061 aluminum alloy offers higher strength and is often used for components requiring higher strength, such as mullions and reinforcing ribs in doors and windows.

Aluminum alloy rods are the main supporting material for building curtain walls, accounting for more than 95% of the metal rods used in curtain walls. 6-series aluminum alloy rods, such as 6061 and 6063, undergo extrusion and serve to manufacture structural components such as curtain wall joists, columns, and beams. These profiles are lightweight, high-strength, corrosion-resistant, and have good stability, enabling them to support panel materials such as glass, stone, and aluminum panels, with a service life of 50-100 years.

Aluminum alloy rods find wide use in interior decorative components, primarily for making ceiling joists, partition frames, decorative moldings, baseboards, and handrails.

Aluminum alloy decorative components offer advantages such as lightweight yet high strength, corrosion resistance, good fire resistance, easy cleaning, and convenient installation. They find wide use in kitchens, bathrooms, balconies, stairwells, and other interior spaces, boasting a long service life and low maintenance costs, meeting the dual demands of modern interior decoration for both aesthetics and functionality.

Aluminum alloy bars can also serve to make building formwork. Compared with traditional steel formwork, aluminum bar formwork has advantages such as light weight, easy assembly and disassembly, and high reusability. In large-span buildings, engineers can process high-strength aluminum alloy bars (such as 6061) into supporting structural components, replacing some of the steel, achieving lightweight construction while improving seismic performance. Aluminum bar formwork can reduce construction costs and improve construction efficiency, making it particularly suitable for high-rise buildings and large-scale engineering projects.

The application of aluminum alloy formwork not only improves construction efficiency and quality, but also achieves the goals of green construction and energy conservation and emission reduction, which is an important direction for the development of modern building industrialization.

6061 aluminum alloy belongs to the Al-Mg-Si system and is a heat-treatable alloy. It has moderate strength, excellent corrosion resistance and weldability, and no tendency for stress corrosion cracking. In the construction industry, 6061 aluminum rods find main use in manufacturing structural components such as building doors and windows, curtain wall profiles, and ceiling decorative surfaces. Due to its excellent machinability and oxidation effect, it allows coloring through anodizing or accepts enamel painting, making it suitable as a building decorative material.

6063 aluminum alloy finds wide use as a building profile material in the Al-Mg-Si alloy system. It has excellent extrusion performance and moderate strength. Its most prominent feature is its excellent thermoplasticity, which allows it to undergo high-speed extrusion into various profiles with complex structures, thin walls, and hollow structures. 6063 aluminum bar have excellent anodizing effects, making them the preferred material for building doors, windows, and curtain wall frames. They also serve in the manufacture of building frameworks and decorative surfaces.

6082 aluminum alloy bar belong to the Al-Mg-Si system of heat-treatable, strengthenable alloys and possess high mechanical properties in the T6 condition. The 6082 aluminum alloy has excellent machinability and can be processed into various profiles through extrusion, rolling, and other processes, making it suitable for structural components such as bridge trusses, tower structures, crane booms, building curtain walls, and door and window frames. Its excellent weldability and formability facilitate on-site construction and the realization of complex shapes.

5052 aluminum alloy bar belong to the Al-Mg series of medium-strength, rust-resistant aluminum alloys and rank among the most widely used alloys in the construction industry. They possess excellent corrosion resistance and weldability, and good cold-working properties. 5052 aluminum bar find main use in manufacturing structural components such as building curtain walls, roof panels, exterior wall cladding panels, and door and window frames, and show particular suitability for construction applications in coastal areas or humid environments.

3003 aluminum alloy possesses moderate strength, good formability and weldability, and excellent corrosion resistance. In the construction industry, 3003 aluminum rods find primary use in manufacturing building curtain walls, roofing panels, and exterior wall cladding panels. Due to their good resistance to atmospheric corrosion, they are suitable for outdoor or humid environments. 3003 aluminum rods also have wide applications in architectural decoration, serving as both structural and decorative materials.

5083 aluminum alloy bars are primarily used in the construction industry for building structures in marine environments and other highly corrosive environments. This material belongs to the Al-Mg series of rust-resistant aluminum alloys and possesses excellent corrosion resistance, particularly against seawater and marine atmospheres, making it an ideal choice for marine and coastal construction. It is especially suitable for large-scale cross-sea bridges, dock facilities, and other building applications requiring high corrosion resistance and lightweight construction.

HSTF is a leading building aluminum bar producer and supplier in China. We specialize in the production, processing, and trading of aluminum rods. With over 18 years of experience in the aluminum industry, we can provide a full range of high-quality aluminum rods at competitive prices.