Professional Supplier

Focus on aluminum bar

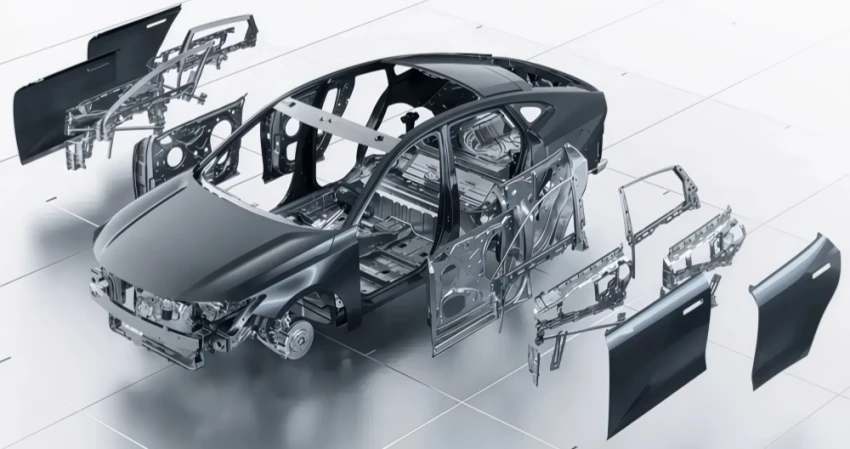

The core advantage of aluminum alloys in the automotive industry lies in their superior lightweight properties, effectively reducing vehicle weight and thus significantly improving fuel economy or the driving range of electric vehicles, while also reducing emissions. This makes them the preferred material for automotive lightweighting. Simultaneously, they possess excellent energy absorption properties, contributing to improved collision safety, as well as good corrosion resistance and high recyclability, meeting the requirements of green manufacturing and the circular economy.

Driven by the wave of automotive electrification and intelligentization, their applications are rapidly expanding from traditional engines and wheels to new energy-specific fields such as battery trays and body structural components. New processes such as integrated die casting can significantly reduce the number of parts and improve production efficiency, while new material technologies such as rare earth modification continue to improve performance and optimize costs.

| Alloy | 1100, 2024, 3003, 3004, 3105, 4032, 5005, 5052, 5083, 5182, 5251, 5754, 6016, 6061, 6181,7003, 7046 |

| Popular Product Types | Aluminum bars, special section profiles, forgings,castings. |

| Classic Applications | Automobile bodies, electronics, automobileinteriors, powertrains and chassis, and automobile parts |

| Certifications Standards | AS9100, OHSAS 18001, ISO14001, ISO 9001, NADCAP HT, NADCAPNDT |

1xxx series aluminum is the purest aluminum currently available. 1100 aluminum is 99% pure and extremelyductile. It also has excellent corrosion resistance and is primarily used for thermal insulation.

2xxx series aluminum contains copper as an alloying element. 2024 finds common use in making pistons, brake parts, rotors, cylinders, wheels, and gears because of its high strength and excellent fatigue resistance.

3003 has high strength, good formability, machinability, and elongation. It is commonly used in automotiveducts, panels, and power castings for hybrid and electric vehicles.

The 5xxx series is one of the most popular series of aluminum alloys for car bodies. Its main alloying element ismagnesium, which is known for increasing strength.

The 6xxx aluminum series has the best extrusion and casting capabilities and offers the best surface finishes.

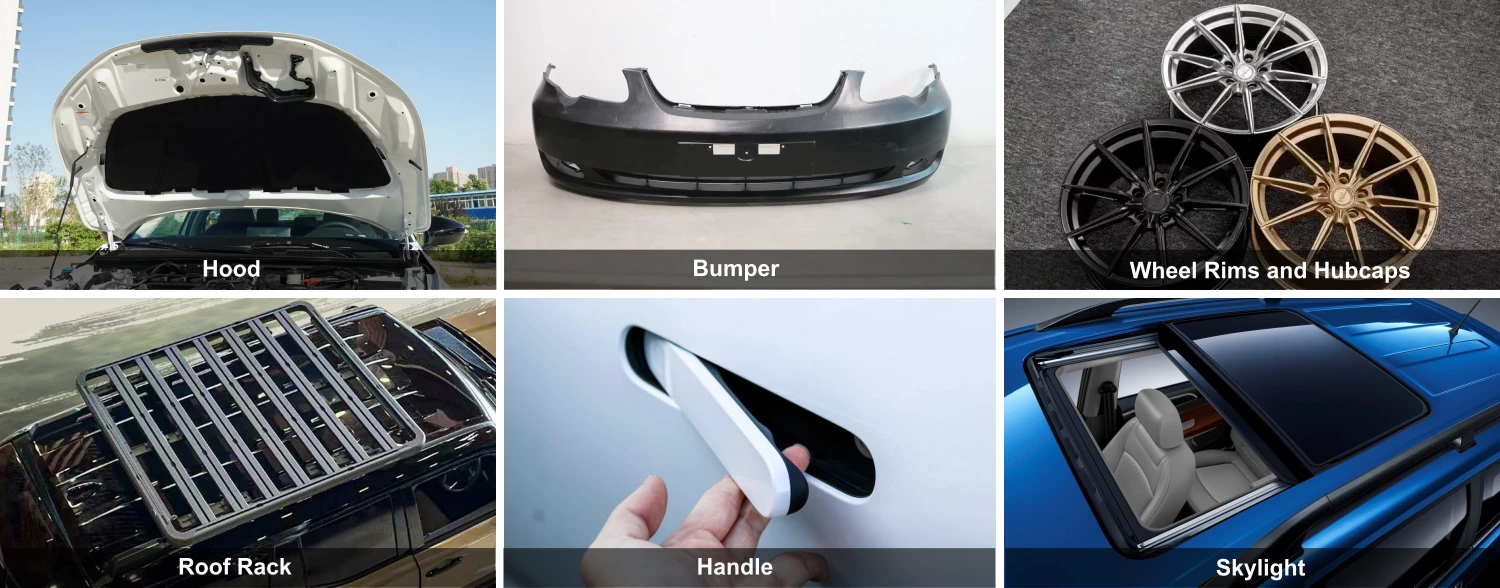

Aluminum alloys used in automotive bodies require excellent corrosion resistance, surface finish, and machinability.Common alloys include 3105, 5005, 5083, 5182, 6016, and 6181.

Although aluminum has a lower electrical conductivity than copper, its low weight makes it ideal for automotive electronics.

1350 alloy finds common use in audio and video equipment, backup cameras and displays, power systems, instruments and gauges, ignition systems, lighting and signals, sensors, switches, and wires in wiring harnesses.

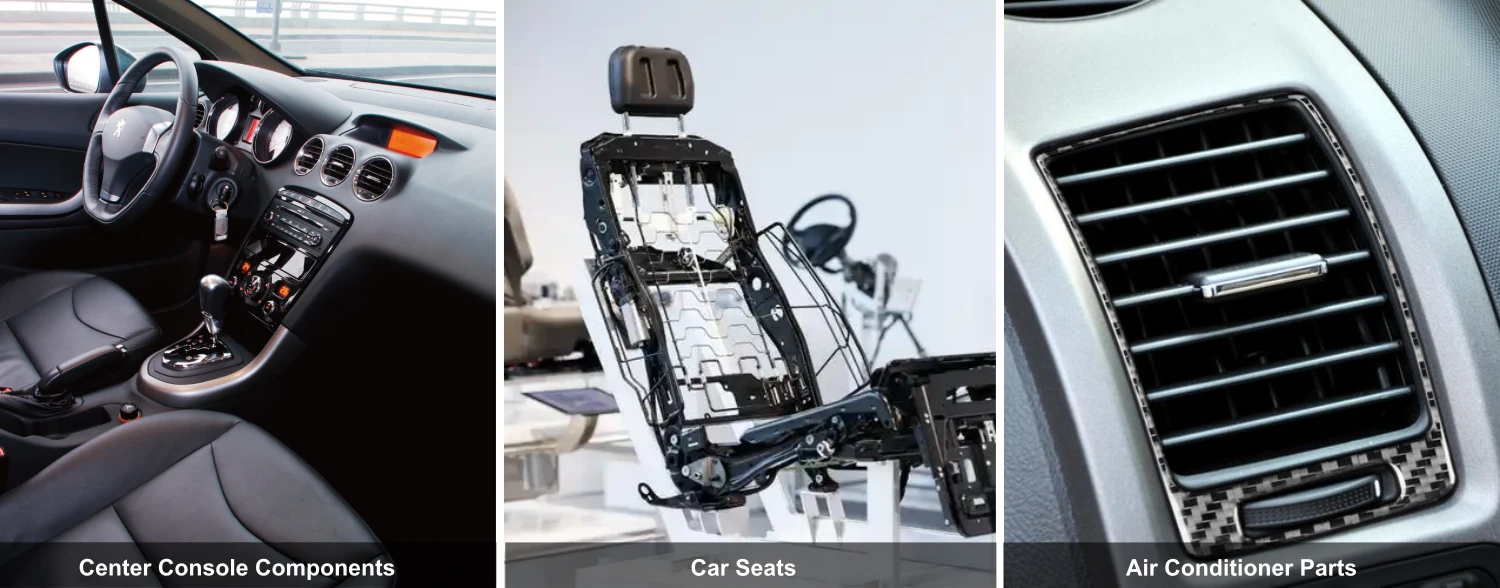

Aluminum alloys find main use in automotive interiors to manufacture structural components such as dashboard frames, door panel reinforcements, and center console supports. Commonly used grades include 5052, 6061, and 6063. These alloys have good strength, formability, and surface treatment properties, enabling lightweighting and improving the interior’s texture.

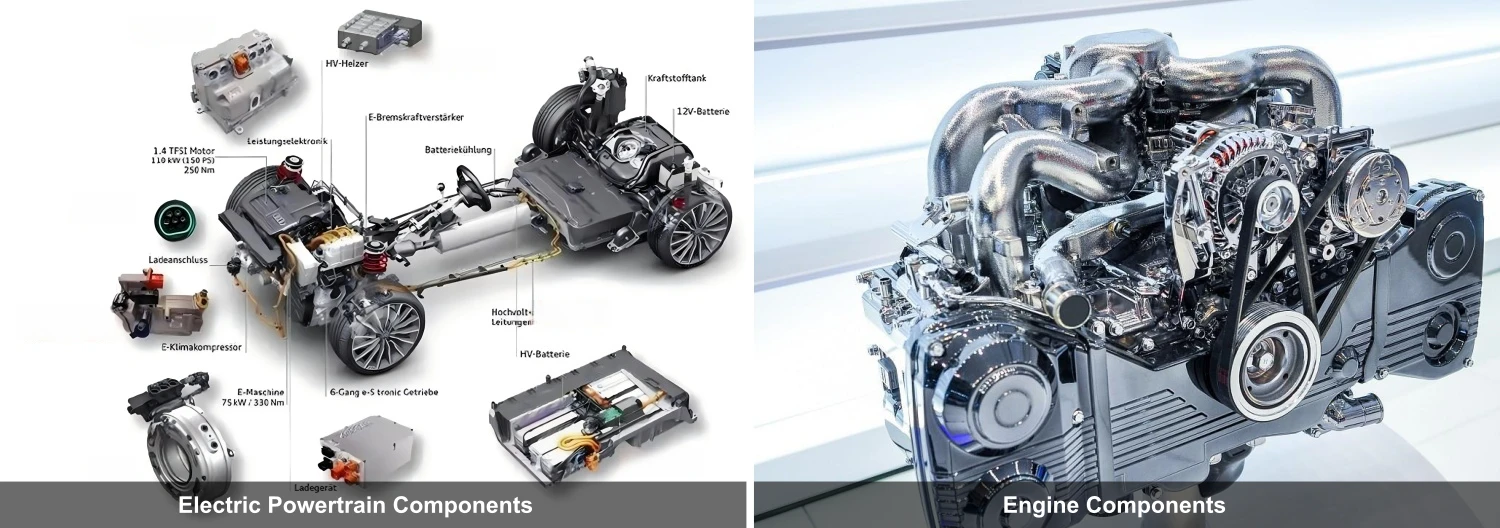

These complex components require high strength, fatigue resistance and weldability. Common alloys are 2024, 4032,5052, 5005, 5083, 6016, 6082 and 6111.

These complex components require high strength, fatigue resistance, and weldability, with common alloys including 2024, 4032, 5052, 5005, 5083, 6016, 6082, and 6111, making them ideal for braking systems, electric powertrain components, engine components, engine cooling systems.

Temper: F, H14, H16, H18

Diameter: 3mm-200mm

Length: 3658/6000mm…

ASTM B211/ASTM B221, EN 754-2, ISO 9001

Temper: F, H14, H16, H18

Diameter: 3mm-200mm

Length: 3658/6000mm…

ASTM B211, ASTM B221; EN573, EN485;

Temper: H12, H14, H16, H18

Diameter: 6mm-100mm

Length: 3000/6000mm

EN 755, EN 754, ASTM B221, ASTM B211

Temper: H12, H14, H16, H18

Diameter: 6mm-100mm

Length: 3000/6000mm

ASTM B221/ B221, ASTM B316, ASME SB211

Temper: F, H112, O, H111

Diameter: 3mm-600mm

Length: 1500/3000/5000/6000mm

ASTM B211, ASME SB211, ASTM B221, ASME SB221

Temper: O,H111,H112,F,H12,H22

Diameter: 3mm-600mm

Length:1000-6000mm

ASTM B221, JIS H4040, ASTM B221, ASTM B565, ASTM B316

Temper: T4, T6, T451, T651, O

Diameter: 3mm-300mm

Length: 4000/6000mm…

ASTM B221, EN 3342

Temper: T6

Diameter: 3mm-600mm

Length: 1000-6000mm

EN573-3, BS EN 755-2, ASTM B221, ASTM B209, EN485

Shandong Hesheng Taifu Aluminum Group Co., Ltd. is a leading automotive aluminum bar producer and supplier in China. And has been recognized as a “China Integrity Enterprise” for many consecutive years. We specialize in the production, processing, and trading of aluminum rods. With over 18 years of experience in the aluminum industry, we can provide a full range of high-quality aluminum rods at competitive prices.