Professional Supplier

Focus on aluminum bar

Aluminum alloys are widely used in the aerospace industry due to their lightweight, high strength, and excellent corrosion resistance. With the continuous advancement of aerospace technology, the demand for materials has been increasing, making the use of aluminum alloys even more crucial.

The density of aluminum alloys is about one-third that of steel, making them an ideal choice in aerospace design. This lightweight characteristic not only reduces the weight of aircraft but also improves fuel efficiency and extends flight range. Additionally, the corrosion resistance of aluminum alloys ensures longevity in various environmental conditions, particularly in high humidity and marine environments.

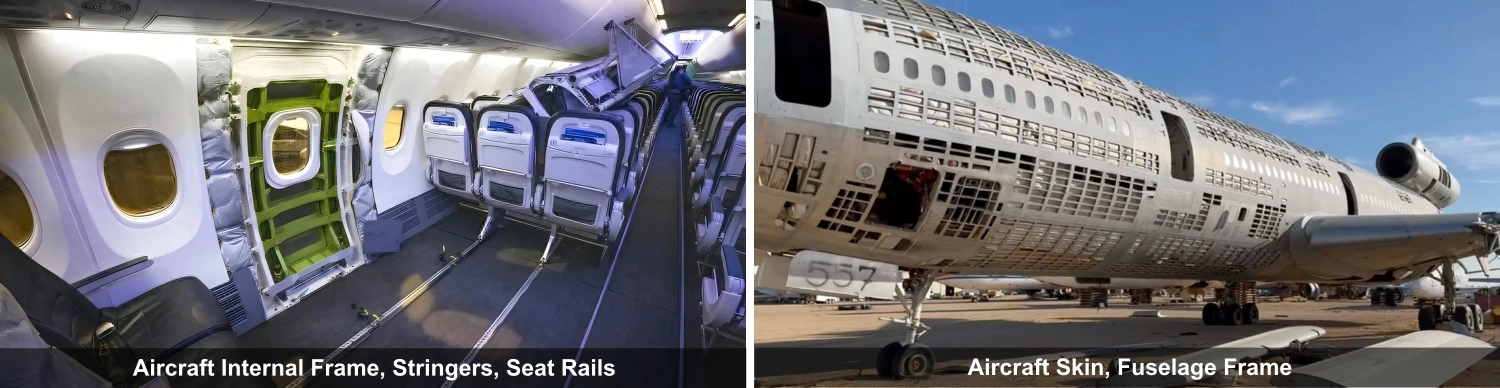

In the aerospace sector, aluminum alloys are primarily used in the manufacture of aircraft fuselages, wings, engine components, and structural parts.

Temper: F, H14, H16, H18

Diameter: 3mm-200mm

Length: 3658/6000mm…

AMS 4102, QQ-A-225/1, ASTM B211-12, EN 573-3:2013

Temper: T3, T6, T8

Diameter: 6mm-200mm

Length: 3000/4000/6000mm…

AMS 4115, AMS 4116; QQ-A-225/3; ASTM B211/B211M

Temper: T3, T6, T8, T651, T6511

Diameter: 6.35mm-254mm

Length: about 12 feet

AMS 4153, UNS A92014, QQ-A-200/2

Temper: F, H14, H16, H18

Diameter: 3mm-200mm

Length: 3658/6000mm…

QQ-A-200/3, AMS 4152, ASTM B211, ASTM B221

Temper: T4, T451

Diameter: 6mm-90mm

Length: 3000/4000mm…

ASTM B211-03, AMS 4118, MIL-STD-1295

Diameter: T6, T851, T8511

With: 5mm-300mm

Length: 1000-6000mm

AMS B211, ASTM B247, AMS QQ-A-200/31, EN 573

Temper: H12, H14, H16, H18

Diameter: 6mm-100mm

Length: 3000/6000mm

ASTM B221-08, EN 573-3, AMS-QQ-A-225/2

Temper: T86, T651

Diameter: 0.125″-16.000″

Length: Up to 144″

AMS 4318, AMS 4319, AMS 4032, AMS-QQA-250/12

Temper: F, H112, O, H111

Diameter: 3mm-600mm

Length: 1500/3000/5000/6000mm…

AMS 4027, AMS 4115, AMS 4123, AMS 4153, AMS 4154, etc.

Temper: F, H112, O, H111

Diameter: 3mm-600mm

Length: 1500/3000/5000/6000mm

AMS 4114, AMS 4015, AMS 4016, QQ-A-225/7, MIL-DTL-32262B

Temper: O,H111,H112,F,H12,H22

Diameter: 3mm-600mm

Length:1000-6000mm

QQ-A-200/4, ASTM B221, AMS 4156, ISO 6361-2, ASME SB221

Temper: T4, T6, T451, T651, O

Diameter: 3mm-300mm

Length: 4000/6000mm…

AMS 4116, AMS 4115, QQ-A-200/8, QQ-A-225/8, EN 3342

Temper: F, H112, O, H111

Diameter: 3mm-600mm

Length: 1500/3000/5000/6000mm…

AMS 4027, AMS 4115, AMS 4123, AMS 4153, AMS 4154, etc.

Temper: T6

Diameter: 3mm-600mm

Length: 1000-6000mm

ASTM B221, AMS 4156, EN 573-3, QQ-A-200/9, QQ-A-225/8

Temper: T6, T651, T73, T74

Diameter: 5.0mm-76.0mm

Stock: 5.0/10.0/20.0/30.0mm…

AMS 4115, ASTM B221, MIL-T-7081E, EN 573-3, etc.

Temper: O, T4, T42, T6, T62

Diameter: 3mm-600mm

Length: 1000-6000mm

AMSQQ, BS 2 L84, ASTM B221, ASME SB221

Temper: F, O, T6, T73511, etc.

Diameter: 5mm-350mm

Length: 2000/2500/3000/4000mm…

AMS 4050, AMS 4201; DMS-2233, BMS 7-323, ASTM B221

Temper: T6, T7351, T651, O

Diameter: φ5-250mm…

Length: 1500/2500/3000mm, etc.

AMS 4122, AMS 4123, AMS 4124, AMS 4186, AMS 4187

Tempers: T3, T6, T8, T651, T6511

Diameter: 6.35mm-254mm

Length: usually 12 feet

ASTM B211, AMS 4123, UNS A97A04, and QQA 200/2

HSTF aerospace aluminum bar shapes : round bar, flat bar, rectangular bar, square bar, hexagonal bar, etc. We also offer deformed forging products, with shapes and sizes that can be customized to customer requirements.