Aluminum Bar

Aluminum bar rod is a solid cylindrical form of aluminum alloy widely used across industries for its exceptional blend of lightweight properties, corrosion resistance, and mechanical strength. Available in a variety of alloys, tempers, and sizes, aluminum bar serves as a fundamental building block for manufacturing, construction, transportation, and precision engineering.

Aluminum bars are produced through extrusion, rolling, or forging processes, resulting in precise dimensions and excellent surface quality. The choice of alloy determines key properties such as strength, weldability, machinability, and environmental resistance. Common alloys include the 1000, 2000, 3000, 5000, 6000, and 7000 series.

Aluminum Alloy Bar Features

Lightweight

Significantly lower density than steel and copper, enabling weight reduction in end products.

Corrosion Resistance

Natural oxide layer protects against atmospheric, marine, and many industrial corrosive agents.

Excellent Machinability

It is easy to cut, drill, mill, turn and manufacture into complex shapes and precision parts.

Diverse Alloy Selection

Tailor material properties to specific mechanical, environmental, and manufacturing needs.

Surface Finish

Compatible with anodizing, polishing, coating, and painting for aesthetic and functional customization.

Recyclability

Fully recyclable without loss of properties, supporting sustainable manufacturing practices.

All our aluminum bars have tight dimensional tolerances and excellent surface quality. Our aluminum bars conform to ASTM, AMS, EN, and ISO standards. We can provide Material Testing Certificates (MTC), chemical composition reports, mechanical property records, and third-party inspection certificates to meet the quality requirements of various industry applications.

HSTF is a professional aluminum bar manufacturer and supplier in China. We possess a mature supply chain system, advanced equipment, and technology, ensuring our products are highly competitive in terms of cost and price, approximately 5% lower than market prices.

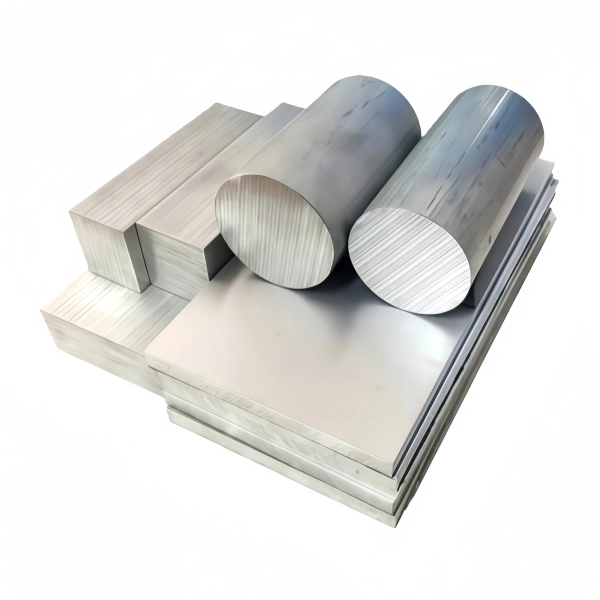

HSTF Aluminum Bar Shape

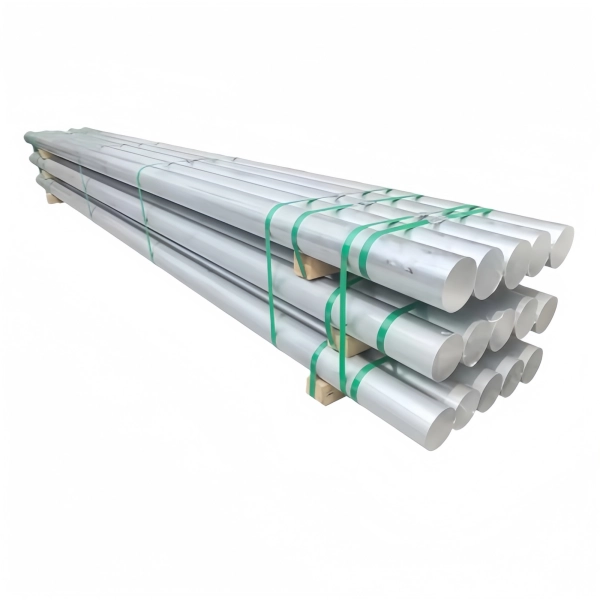

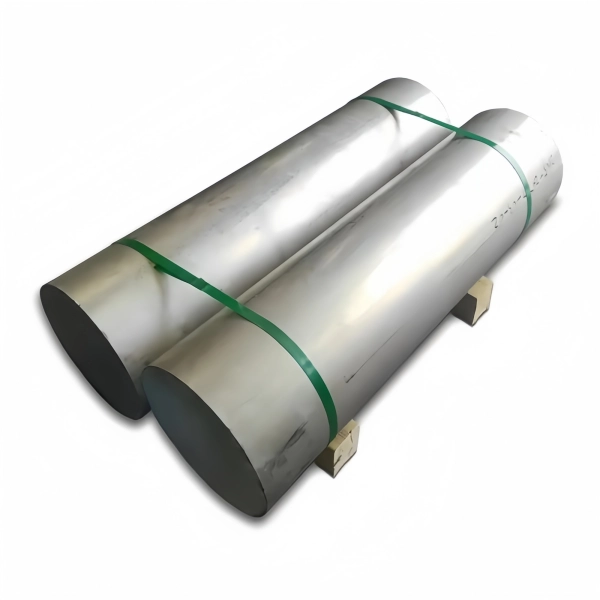

Aluminum Round Bar

The aluminum round bars can be obtained through extrusion and drawing, and are the most widely used products; further processing such as sawing and polishing can be provided.

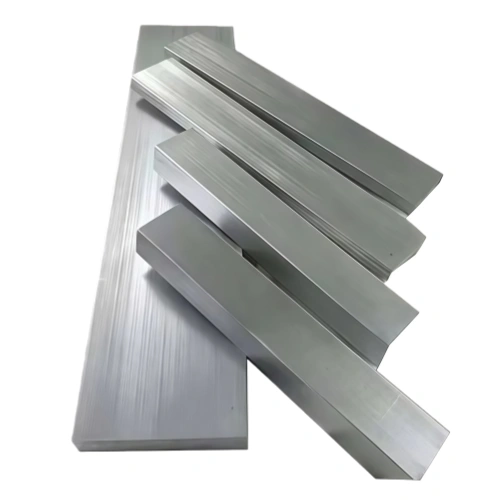

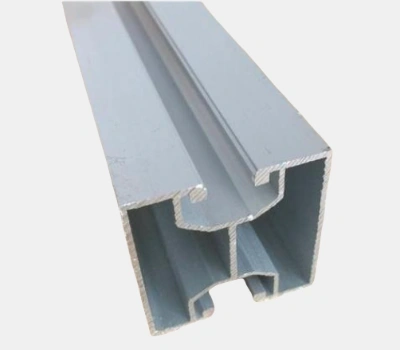

Aluminum Flat Bar

Extruded aluminum bar with a 90 degree acute angle, which requires higher extrusion performance and is often used in the power industry after certain processing.

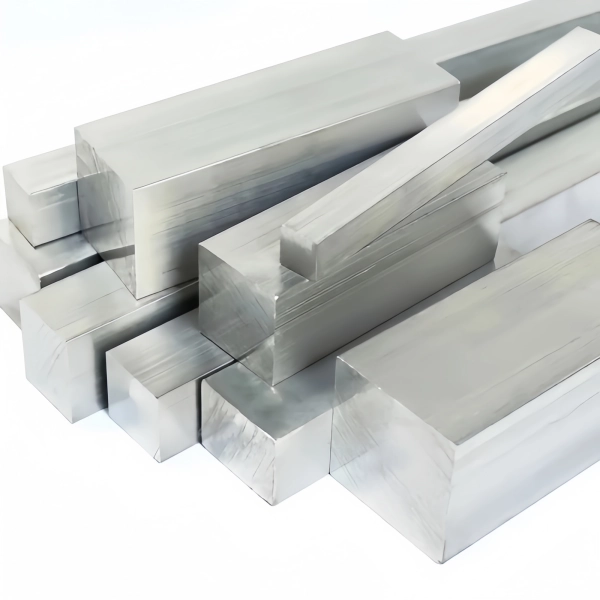

Aluminum Square Bar

Light weight, high stability, and corrosion resistance, and is widely used in various industries such as buildings, manufacturing, and parts processing.

Aluminum Hex Bar

Featuring a hexagonal cross-section, this bar is ideal for applications requiring high strength and precision, such as machinery parts and automotive parts.

More Precision Customization

HSTF also provides high-precision customized processing services, offering tailored solutions for various industries. Our factory possesses advanced German precision machining equipment and hydraulic extrusion technology, equipped with over 50 aluminum CNC machining centers, 20 sawing machines, and 3 ultra-high pressure waterjet cutting systems. It is capable of processing precise and complex cross-sectional contours and customizing complex aluminum extrusions.

HSTF Aluminum Bar Process Type

Extruded Aluminum Bar

HSTF’s high-quality aluminum extruded bars are produced using advanced extrusion presses with capacities ranging from 360 to 1800 tons. All products are controlled by a PLC system to ensure precision and consistency. China Railway can produce various alloy bars, including 2024, 2014, 2017A, 2618, 5083, 6061, and 7075. These bars are widely used in industries such as aerospace, automotive, and construction, providing excellent strength, durability, and corrosion resistance for high-performance applications.

Cold Finish Aluminum Bar

Cold-finished(CF) aluminum bars are produced using a cold-drawing process, repeatedly drawn to achieve the desired diameter. Our cold-finished aluminum bar feature precise dimensions (precise tolerances), a smooth surface (reducing machining/coating requirements), enhanced strength through strain hardening, and a stable grain structure for reliable performance. Suitable for precision parts in aerospace, automotive, and medical fields. Ideal for high-performance, low-maintenance applications.

Forged Aluminum Bar

HSTF forged aluminum bars have a relatively dense microstructure, making them less prone to internal defects; they find wide use in processing components requiring high strength and wear resistance. Maximum diameter: 600mm.

Hot-selling alloys: 2A01, 2A02, 2A10, 2A11, 2A12, 3A21, 3003, 3004, 3005, 5A02, 5A03, 5A05, 5B05, 5A06, 5050, 5052, 5056, 5086, 6A02, 6101, 6005, 6063, 6061, 6082, 7A04.

Large Diameter Aluminum Bar

HSTF supplies large-diameter bars, aluminum billets, and cast rods in flexible shapes and sizes, supporting diameters up to 650mm. These products are ideal for applications requiring low density, large cross-sections, or custom geometries. They are widely used in aerospace, semiconductor, tire mold, and heavy industrial parts.

HSTF Aluminum Bar Rod Series

All HSTF products comply with ASTM, AMS, and ISO international standards, ensuring high quality. We also offer customization services, including dimensional adjustments, surface treatments, and precision machining. With over 20 years of expertise in aluminum and rigorous quality control, we can provide solutions for applications in construction, transportation, electrical engineering, and high-performance industries.

1000 Series (Pure Aluminum Rod)

1000 series aluminum rod consist primarily of pure aluminum (99%+Al), offering excellent corrosion resistance, high thermal/electrical conductivity, and ductility. Their low strength limits their load-bearing applications, but their flexibility facilitates shaping. They are common in chemical equipment, conductors, reflectors, and decorative components.

1050 Aluminum Bar

Aluminum ≥ 99.5%; possesses high plasticity, corrosion resistance, and good electrical conductivity; used in reflectors, chemical containers, etc.

1060 Aluminum Bar

Aluminum≥99.6; with good elongation, tensile strength, plasticity, corrosion resistance, conductivity; Widely used in products with low strength, etc.

1070 Aluminum Bar

The 1070 aluminum bar typically contain over 99.7% aluminum and are renowned for their excellent electrical conductivity and corrosion resistance.

1100 Aluminum Bar

Alloy 1100 is renowned for its excellent corrosion resistance, machinability, and high purity, making it a versatile choice for both chemical and decorative applications.

2000 Series (Aluminum-Copper Alloy Rod Bar)

Typically containing over 99% aluminum, these bars exhibit excellent corrosion resistance and electrical conductivity. However, their relatively low strength limits their suitability for conductive materials and chemical equipment.

2011 Aluminum Bar

Due to the presence of low-melting point phases Pb7Bi3 and Bi in the alloy, high-speed cutting and large feed rate can be used.

2014 Aluminum Bar

Hard aluminum alloy with good thermal strength. Used for heavy-duty aircraft, structural and suspension system components.

2017 Aluminum Bar

Good cutting performance, high strength and excellent fatigue strength. When temperature is above 125 ℃, its strength is higher than 7075.

2024 Aluminum Bar

With exceptional strength, machinability, and surface finish, they are ideal for high-performance and precision components.

2219 Aluminum Bar

High-strength, heat-treatable alloy with excellent mechanical properties, good fracture toughness, and resistance to stress corrosion.

2618 Aluminum Bar

Designed specifically for applications requiring excellent high-temperature performance, high strength, and fatigue resistance.

3000 Series (Aluminum-Manganese Alloy Rod Bar)

With an aluminum content typically above 99%, they possess excellent corrosion resistance and electrical conductivity. However, their strength is relatively low, making them suitable for conductive materials and chemical equipment.

3003 Aluminum Bar

3003 material has excellent rust prevention properties and is often used for parts that are easy to process and form, highly corrosion resistant, and have good weldability.

3A21 Aluminum Bar

3A21 is renowned for its excellent corrosion resistance, good formability, and moderate strength. It is an ideal material for applications requiring both durability and ease of processing.

5000 Series (Aluminum-Magnesium Alloy Rod)

5000 series aluminum bars, alloyed with magnesium, offer excellent corrosion resistance, weldability, and moderate strength. Lightweight yet durable and easy to form, they are ideal for marine, automotive, and construction applications—truck bodies, ship plates, fuel tanks. Not heat-treatable.

5005 Aluminum Bar

Medium-strength, non-heat-treatable aluminum-magnesium alloy. Due to its excellent corrosion resistance and good formability, it is a popular choice for construction and marine applications.

5052 Aluminum Bar

Excellent corrosion resistance, formability, and weldability make it suitable for applications in harsh environments. It is an important material in the aerospace and industrial fields.

5056 Aluminum Bar

5056 aluminum alloy bars are known for their excellent corrosion resistance (especially in marine and corrosive industrial environments) as well as good strength and ductility.

5083 Aluminum Bar

High-strength, non-heat-treatable aluminum-magnesium alloys are designed for applications requiring marine environments. They offer excellent corrosion resistance and weldability.

5A02 Aluminum Bar

With moderate strength, good mechanical properties, and machinability, it is suitable for marine, construction, and general industrial applications.

5A06 Aluminum Bar

Premium marine-grade alloy. Features excellent corrosion resistance, outstanding weldability, and balanced mechanical properties. Suitable for marine or industrial environments.

5754 Aluminum Bar

Excellent corrosion resistance, good weldability, and high fatigue strength. Suitable for industries with extremely high reliability requirements and harsh environmental conditions.

5086 Aluminum Bar

It has excellent corrosion resistance and good weldability. It often carries the designation “sister alloy” of 5083 aluminum alloy, but with higher strength.

6000 Series (Aluminum-Magnesium-Silicon Alloy Rod)

The 6000 series aluminum bar, alloyed with magnesium and silicon, is heat-treatable, offering good strength, corrosion resistance, and weldability. Lightweight and easily formed, it’s widely used in automotive frames, structural parts, and machinery. Its balanced properties suit both structural and aesthetic applications, making it versatile for manufacturing.

6061 Aluminum Bar

One of the most widely used and best-balanced aluminum alloys. It achieves an optimal balance of strength, corrosion resistance, and machinability, making it suitable for a wide range of industrial and commercial applications.

6063 Aluminum Bar

Designed specifically for architectural, decorative, and structural applications. Offers excellent formability, corrosion resistance, and surface finish. Particularly suitable for applications requiring high aesthetic appeal.

6082 Aluminum Bar

One of the most widely used aluminum alloys in structural load-bearing and industrial applications. Particularly suitable for applications requiring extremely high strength, reliability, and durability.

7000 Series (Aluminum-Zinc Alloy Rod)

7000 series aluminum bar, alloyed with zinc (plus magnesium/copper), is heat-treatable, delivering very high strength—ideal for aerospace, automotive, and sports gear. Lightweight yet robust, it balances strength and formability, though corrosion resistance is moderate (needs coating). Preferred for high-load, weight-sensitive structural parts.

7050 Aluminum Bar

The 7050 was developed specifically for aerospace and high-performance engineering applications where a combination of high strength, fracture toughness, and resistance to stress corrosion cracking (SCC) is critical.

7075 Aluminum Bar

Excellent fatigue and corrosion resistance, while possessing mechanical properties comparable to many types of steel. It is the material of choice for aerospace, defense, and high-performance applications.

7A04 Aluminum Bar

Renowned for its superior mechanical properties and reliability in the most demanding engineering applications, it is an essential material for aerospace, transportation, defense, and advanced industrial applications.

7005 Aluminum Bar

Heat-treatable aluminum-zinc-magnesium alloys combine high strength, good weldability, and lightweight properties. They are widely used in welded structures where high strength and fracture toughness are required.

HSTF Aluminum Bar Customization Options

Professional Aluminum Rod Processing Services

HSTF offers a full range of customized aluminum rod services to meet the diverse needs of various industries.

One-Stop Solution

High Precision and Consistency

Global Compliance and Certification

Professional Technical Team Support

Size Customization

Aluminum bars can be customized in length, diameter, and tolerance according to customer requirements. We ensure high-precision products that meet strict dimensional standards.

Alloy Composition

We customize alloy compositions to meet specific application requirements. We offer a full range of aluminum bars from 1xxx to 7xxx series to satisfy diverse performance needs.

Shape Customization

Provide various shapes, including round bars, square bars, hex bars, flat bars, and more, to suit different application scenarios. We also offer custom shapes and precision profile machining.

Surface Treatment

Offer surface treatments such as anodizing, electroplating, and painting to enhance corrosion resistance and appearance, fulfilling both functional and decorative needs.

Heat Treatment

Depending on the application, heat treatment processes such as quenching and aging are provided to improve the mechanical properties and durability of aluminum bars.

Cutting Services

Perform precise cutting to customer-specified sizes or shapes, ensuring smooth, burr-free cutting surfaces suitable for precision machining or direct use.

Bending Services

Deliver professional aluminum bar bending services according to customer drawings or requirements, ensuring high accuracy and surface quality, ideal for structural and decorative applications.

Packaging and Logistics

Offer professional packaging services to ensure the safety of products during transportation, with global logistics support for prompt delivery to meet customer demands.

Project Application Solutions

At HSTF, our expert technical team can provide comprehensive one-stop solutions specifically for your project application needs.

Aluminum Alloy Bar for Aerospace

- Recommended Alloys: 7075, 7050, 2024, 2219

- Services: Precision cutting for high-accuracy aerospace componentsHeat treatment (e.g., T6, T73) to enhance strength and fatigue resistanceSurface treatment (anodizing, anti-corrosion coating) for durability.

Aluminum Bar for Marine industry

Recommended Alloys: 5083, 5086, 5754

Services: Special alloy customization for saltwater corrosion resistanceCutting and packaging for easy transportation and installationHeat treatment to enhance fatigue strength.

HSTF Aluminum Bar for Building and Decoration

Recommended Alloys: 6063, 6061, 5086

Services: Custom sizes are available to meet installation requirements; decorative surface treatments (anodizing, polishing) enhance aesthetics and durability; bending services are available to meet complex architectural design needs.

Aluminum Bar for Automotive Industry

- Recommended Alloys: 6061, 6082, 5083, 4032

- Services: Custom bending to fit structural partsSurface coating to improve aesthetics and wear resistanceSmall-batch customization for prototype development.

Aluminum Bar for Tooling and Mold

Recommended Alloys: 6061, 6063, 5052

Services: Custom tolerances are available to meet high-precision machining requirements; surface treatments (coatings, anodizing) are available to enhance corrosion resistance; and small-batch customization is available for tooling and mold making.

Aluminum Bar for Industrial Machinery

Recommended Alloys: 6061, 6063, 7075, 2024, 3003

Services: Cutting, polishing, stamping, bending, machining, pipe end forming, etc., suitable for assembly and piping needs; Anodizing (including colored anodizing), hard anodizing, sandblasting, spraying, etc., taking into account both corrosion resistance and appearance.

Packaging

- Inner protection: Each aluminum rod is wrapped in PE film, with optional paper, cardboard, or foam layers formoisture and scratch resistance.

- Bundle securing: Aluminum rods are bundled and reinforced with steel or PET straps, with protective padding toprevent loosening and abrasion.

- Outer packaging: Bulk orders are packed in sturdy wooden crates or pallets, with optional export-gradefumigation and moisture-proof lining for compression and shock resistance.

Why Choose Us?

Quality Assurance – All products comply with ASTM, ISO and other international standards, ensuring high purity, uniformstructure, and stable performance.

Professional Supplier – Professional aluminum alloy bar rod supplier in China. We have an advanced factory to ensure quality and efficiency.

Competitive Price – The mature supply chain system, advanced equipment and technology ensure that our products are highly competitive in cost and price.

Superior Quality – Quality supervision on whole process of production from raw materials, manufacturing, packaging, warehousing till container loading.

On-Time Delivery – The mature logistics management system and company self owned freight forwarder ensure that our OTD rate reaches 100%.

HSTF Aluminum Bar Size and Inventory Table

- Inventory size, quick delivery within 7-30 days.

- We update our inventory frequently. If you cannot find the specification you need, please contact us.

Aluminum Round Bar Size |

|||||

| Inch Diameter/in | Metric Diameter/mm | Inch Diameter/in | Metric Diameter/mm | Inch Diameter/in | Metric Diameter/mm |

| 1/8″ | 3mm | 1-7/8″ | 47mm | 6-1/4″ | 160mm |

| 3/16″ | 5mm | 2″ | 50mm | 6-3/4″ | 170mm |

| 1/4″ | 6mm | 2-1/8″ | 54mm | 7″ | 180mm |

| 5/16″ | 8mm | 2-1/4″ | 57mm | 7-1/2″ | 190mm |

| 3/8″ | 10mm | 2-3/8″ | 60mm | 8″ | 200mm |

| 7/16″ | 11mm | 2-1/2″ | 64mm | 8-1/4″ | 210mm |

| 1/2″ | 12.7mm | 2-5/8″ | 67mm | 8-5/8″ | 220mm |

| 9/16″ | 14mm | 2-3/4″ | 70mm | 9″ | 230mm |

| 5/8″ | 16mm | 3″ | 75mm | 9-3/8″ | 240mm |

| 11/16″ | 17mm | 3-1/8″ | 80mm | 9-7/8″ | 250mm |

| 3/4″ | 19mm | 3-1/4″ | 83mm | 10-1/4″ | 260mm |

| 13/16″ | 20mm | 3-3/8″ | 85mm | 10-5/8″ | 270mm |

| 7/8″ | 22mm | 3-1/2″ | 90mm | 11″ | 280mm |

| 1″ | 25mm | 3-5/8″ | 92mm | 11-3/8″ | 290mm |

| 1-1/16″ | 28mm | 3-3/4″ | 95mm | 11-7/8″ | 300mm |

| 1-1/8″ | 30mm | 4″ | 100mm | 12-1/4″ | 310mm |

| 1-1/4″ | 32mm | 4-3/8″ | 110mm | 12-5/8″ | 320mm |

| 1-3/8″ | 35mm | 4-3/4″ | 120mm | 13″ | 330mm |

| 1-1/2″ | 38mm | 5-1/8″ | 130mm | 13-3/8″ | 340mm |

| 1-5/8″ | 40mm | 5-1/2″ | 140mm | 13-3/4″ | 350mm |

| 1-3/4″ | 45mm | 6″ | 150mm | ||

Aluminum Square Bar Size |

|||||

| Metric Size/in | Metric Size/mm | Inch Size/in | Metric Size/mm | Inch Size/in | Metric Size/mm |

| 1/4″ | 6mm | 1-5/8″ | 40mm | 3-3/8″ | 85mm |

| 3/8″ | 10mm | 1-3/4″ | 45mm | 3-1/2″ | 90mm |

| 1/2″ | 12.7mm | 2″ | 50mm | 3-3/4″ | 95mm |

| 5/8″ | 16mm | 2-1/4″ | 55mm | 4″ | 100mm |

| 3/4″ | 19mm | 2-3/8″ | 60mm | 4-3/8″ | 110mm |

| 7/8″ | 22mm | 2-1/2″ | 64mm | 4-3/4″ | 120mm |

| 1″ | 25mm | 2-3/4″ | 70mm | 5-1/8″ | 130mm |

| 1-1/8″ | 30mm | 3″ | 75mm | 5-1/2″ | 140mm |

| 1-3/8″ | 35mm | 3-1/8″ | 80mm | 6″ | 150mm |

Aluminum Hex Bar Size |

|||||

| Inch Size/in | Metric Size/mm | Inch Diameter/in | Metric Diameter/mm | Inch Size/in | Metric Size/mm |

| 1/4″ | 6mm | 1-1/2″ | 38mm | 3-3/8″ | 85mm |

| 3/8″ | 10mm | 1-3/4″ | 45mm | 3-1/2″ | 90mm |

| 1/2″ | 12.7mm | 2″ | 50mm | 3-3/4″ | 95mm |

| 5/8″ | 16mm | 2-1/8″ | 55mm | 4″ | 100mm |

| 3/4″ | 19mm | 2-3/8″ | 60mm | 4-3/8″ | 110mm |

| 7/8″ | 22mm | 2-1/2″ | 64mm | 4-3/4″ | 120mm |

| 1″ | 25mm | 2-3/4″ | 70mm | 5-1/8″ | 130mm |

| 1-1/8″ | 30mm | 3″ | 75mm | 5-1/2″ | 140mm |

| 1-1/4″ | 32mm | 3-1/8″ | 80mm | 6″ | 150mm |

luminum Flat Bar Size |

|||||

| Metric Size/in | Metric Size/mm | Inch Size/in | Metric Size/mm | Inch Size/in | Metric Size/mm |

| 1/16″ x 3/8″ | 1.5mm x 10mm | 3/16″ x 2″ | 5mm x 50mm | 3/8″ x 1-1/2″ | 10mm x 38mm |

| 1/16″ x 1/2″ | 1.5mm x 13mm | 3/16″ x 2-1/2″ | 5mm x 64mm | 3/8″ x 2″ | 10mm x 50mm |

| 1/16″ x 3/4″ | 1.5mm x 19mm | 3/16″ x 3″ | 5mm x 76mm | 3/8″ x 2-1/2″ | 10mm x 64mm |

| 1/16″ x 1″ | 1.5mm x 25mm | 3/16″ x 4″ | 5mm x 102mm | 3/8″ x 3″ | 10mm x 76mm |

| 1/8″ x 3/8″ | 3mm x 10mm | 1/4″ x 3/8″ | 6mm x 10mm | 3/8″ x 4″ | 10mm x 102mm |

| 1/8″ x 3/4″ | 3mm x 19mm | 1/4″ x 1/2″ | 6mm x 13mm | 3/8″ x 5″ | 10mm x 127mm |

| 1/8″ x 1″ | 3mm x 25mm | 1/4″ x 3/4″ | 6mm x 19mm | 1/2″ x 3/4″ | 13mm x 19mm |

| 1/8″ x 1-1/4″ | 3mm x 32mm | 1/4″ x 1″ | 6mm x 25mm | 1/2″ x 1″ | 13mm x 25mm |

| 1/8″ x 1-1/2″ | 3mm x 38mm | 1/4″ x 1-1/4″ | 6mm x 32mm | 1/2″ x 1-1/4″ | 13mm x 32mm |

| 1/8″ x 2″ | 3mm x 50mm | 1/4″ x 1-1/2″ | 6mm x 38mm | 1/2″ x 1-1/2″ | 13mm x 38mm |

| 1/8″ x 2-1/2″ | 3mm x 64mm | 1/4″ x 2″ | 6mm x 50mm | 1/2″ x 2″ | 13mm x 50mm |

| 1/8″ x 3″ | 3mm x 76mm | 1/4″ x 2-1/2″ | 6mm x 64mm | 1/2″ x 2-1/2″ | 13mm x 64mm |

| 3/16″ x 1/2″ | 5mm x 13mm | 1/4″ x 3″ | 6mm x 76mm | 1/2″ x 3″ | 13mm x 76mm |