7A04 Aluminum Bar

7A04 aluminum bar rod is an ultra-high-strength aluminum alloy belonging to the Al-Zn-Mg-Cu system. It has significantly high strength, good corrosion resistance and excellent processing performance. This aluminum alloy is widely used in fields such as aerospace, automotive and defense industries that require high strength and durability. Its advantage lies in maintaining stable mechanical properties in high-stress environments while providing a lightweight solution.

7A04 Aluminum Bar Rod Features

High Strength

The tensile strength of 7A04 aerospace aluminum rod can reach over 500MPa, making it one of the strongest aluminum alloys and able to meet the high strength requirements of the aerospace industry.

Lightweight

7A04 aviation aluminum rods have a low density and are lighter than metals such as steel and titanium alloys, which can effectively reduce aircraft weight and improve load capacity and economy.

Good corrosion resistance

The surface of 7A04 aluminum rods undergoes special treatment, giving them excellent corrosion resistance and enabling long-term use in harsh environments such as the atmosphere and seawater.

Excellent Processing Performance

7A04 aerospace aluminum rod bar have excellent machinability and can be processed into parts of various complex shapes using various processing techniques.

Our 7A04 aluminum bars are manufactured to stringent dimensional and metallurgical standards, ensuring uniform mechanical properties, excellent straightness, and superior surface quality. Our 7A04 aluminum bars conform to ASTM B211, AMS 4123, UNS A97A04, and QQA 200/2. We can provide Material Testing Certificates (MTC) and third-party inspection reports upon request, ensuring full traceability and compliance with aerospace, defense, and industrial quality systems.

HSTF is a professional 7A04 aluminum rod bar manufacturer and supplier in China. We possess a mature supply chain system, advanced equipment, and technology, ensuring our products are highly competitive in terms of cost and price, approximately 5% lower than market prices.

Specification

| Alloy | 7A04 Aluminum |

| Material Tempers | T3, T6, T8, T651, T6511 |

| Standard | UNS A97A04, QQA 200/2 |

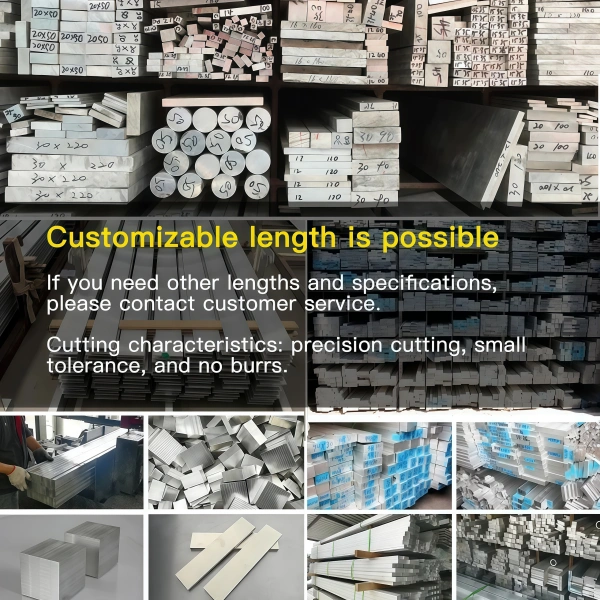

| Diameter | From 0.25″ (6.35 mm) to 10″ (254 mm) |

| Length | Usually about 12 feet (3.66 meters), custom lengths available |

| Other Dimensions | Varies based on application needs |

| Package | 1.Inner protection: We wrap each aluminum rod in PE film, with optional paper, cardboard, or foam layers to resist moisture and scratches.

2.Bundle securing: The packaging process bundles and reinforces aluminum rods with steel or PET straps, with protective padding to prevent loosening and abrasion. 3.Outer packaging: We pack bulk orders in sturdy wooden crates or pallets, with optional export-grade fumigation and moisture-proof lining for compression and shock resistance. |

7A04 Aluminum Bar Chemical Composition

| Element | Composition % |

| Si | 0.5 |

| Fe | 0.5 |

| Cu | 1.4-2.0 |

| Mn | 0.20-0.60 |

| Mg | 1.8-2.8 |

| Ti | 0.1 |

| Cr | 0.10-0.25 |

| Zn | 5.0-7.0 |

| Other (Each) | 0.0-0.05 |

7A04 Aluminum Bar Physical Properties

| Properties | 7A04 |

| Density | 2.72 g/cm³ |

| Melting Point | 562-646°C |

| Thermal Conductivity | 150 W/m·K |

| Coefficient of Thermal Expansion | 23.2 µm/m·°C |

| Electrical Conductivity | 40 % IACS |

| Tensile strength Rm/Mpa | 530 |

| Yield strength Rp0.2/Mpa | 400 |

| Elongation | 6% |

| Hardness | 156HB |

HSTF 7A04 Aluminum Bar Product

7A04 Extrusion Aluminum Bar

Temper: O,T6,T6511,T73,T73511,T76,T76511

DIA: 0.4″-16″(10-420mm)

7A04 Cold Finished Aluminum Bar

Temper: O,T6,T651,T73,T7351

DIA: 0.2″-8″(5-200mm)

7A04 Forged Aluminum Bar

Temper: T6,T652,T73,T7352

DIA: 7.8″-40″(200-1000mm)

7A04-O Extrusion Aluminum Bar

It possesses high strength, corrosion resistance, and good formability, and exists in a soft “O” state. Lightweight yet robust, it is ideal for aerospace, automotive, and structural applications. Excellent weldability and thermal stability ensure its reliability in harsh environments.

7A04-T6/T6511 Extrusion Aluminum Bar

Provides peak strength and toughness under T6/T6511 tempering conditions. It retains its lightweight, excellent corrosion resistance, and weldability. It is ideal for aerospace, defense, and high-load structures, meeting the requirements of extreme machinery and environments.

7A04-T73/T73511 Extrusion Aluminum Bar

It possesses high strength and exhibits excellent resistance to stress corrosion after aging treatment. In the T73/T73511 condition, it maintains good toughness, weldability, and dimensional stability. It is an ideal choice for aerospace structural engineering applications.

7A04-T76/T76511 Extrusion Aluminum Bar

Through controlled over-aging treatment, it exhibits excellent resistance to stress corrosion and spalling, while maintaining good toughness and dimensional stability. It is ideal for applications requiring extremely high reliability and long-term performance.

7A04-T652 Forged Aluminum Bar

Exhibits high strength and toughness in the T652 condition (stress-relieved). It also demonstrates excellent fatigue resistance and corrosion resistance. Suitable for aerospace, defense, and high-load components, ensuring reliable operation under extreme stress.

7A04-T7352 Forged Aluminum Bar

The T7352 stress-relief treatment ensures excellent toughness, dimensional stability, and weldability. Lightweight and durable, this aluminum rod is ideal for aerospace, defense, and heavy-duty components operating in harsh environments.

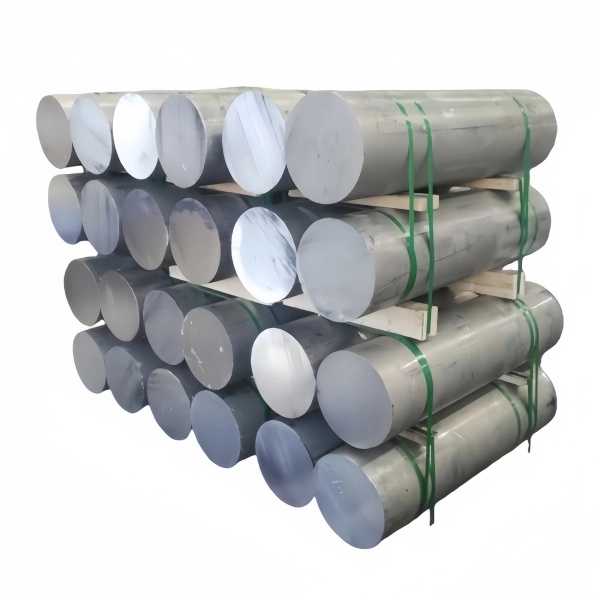

7A04 Aluminum Round Bar

7A04 aluminium round bar is valued for its uniform radial strength and torsional resistance, making it ideal for shafts, axles and pins. Its circular cross‑section reduces stress concentrations and eases machining. High strength and corrosion resistance, available in multiple tempers, suit dynamic load applications in aerospace and automotive fields.

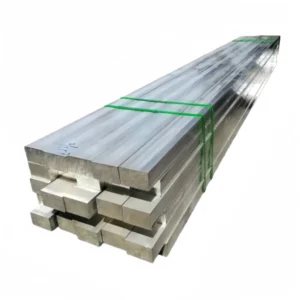

7A04 Aluminum Flat Bar

7A04 aluminium flat bar offers a high strength‑to‑weight ratio with broad planar surfaces, perfect for brackets, frames and mounting plates. Easy to weld and machine, its shape allows efficient material use and surface contact. Different tempers balance formability, strength and stress‑corrosion resistance for versatile structural and mechanical roles.

7A04 Aluminum Square Bar

7A04 aluminium square bar provides equal strength in all four sides, giving excellent rigidity and alignment for precision components. Its geometry aids stable fixturing and machining accuracy. With high strength, toughness and corrosion resistance across tempers, it is preferred for machine bases, structural supports and high‑load frameworks.

HSTF 7A04 T6 Aluminum Bar Stock |

|||||||

| 0.394″ | 0.63″ | 0.787″ | 0.984″ | 1.181″ | 1.378″ | 1.575″ | 1.772″ |

| 1.969″ | 2.165″ | 2.362″ | 2.559″ | 2.756″ | 2.953″ | 3.15″ | 3.346″ |

| 3.543″ | 3.74″ | 3.937″ | 4.134″ | 4.331″ | 4.528″ | 4.724″ | 4.921″ |

| 5.118″ | 5.315″ | 5.512″ | 5.709″ | 5.906″ | 6.102″ | 6.496″ | 6.693″ |

| 6.89″ | 7.087″ | 7.283″ | 7.48″ | 7.874″ | 8.268″ | 8.661″ | 9.016″ |

| 9.055″ | 9.449″ | 9.843″ | 10.236″ | 11.024″ | 11.417″ | 11.811″ | 12.205″ |

| 12.598″ | 12.992″ | 13.386″ | 13.78″ | 15.63″ | |||

- Inventory size, quick delivery within 7-10 days.

- Our inventory is updated frequently. If you cannot find the specification you need, please contact us.

Application

Aerospace

High strength‑to‑weight ratio and excellent fatigue resistance make 7A04 ideal for critical aircraft and spacecraft structures.

- Wing spars and ribs: ultra‑strong bars bear aerodynamic loads and ensure flight safety.

- Fuselage frame connectors: tough bars join sections reliably under pressurization and vibration.

- Satellite boom and bracket components: lightweight bars reduce launch mass while withstanding space conditions.

High‑Performance Vehicles

Superior mechanical properties help 7A04 deliver speed, endurance, and safety in racing and specialty transport.

- Racing car suspension arms and roll‑cage bars: high strength absorbs crash energy and improves handling.

- Motorcycle frame and swingarm components: lightweight bars boost agility and reduce unsprung mass.

- High‑speed train bogie frames: tough bars ensure stability and longevity at elevated speeds.

Defense & Military

Exceptional strength and impact resistance suit 7A04 for armored and high‑stress defense equipment.

- Armored vehicle chassis and turret supports: bars resist ballistic impacts and heavy loads.

- Artillery and missile launcher frames: strong bars maintain accuracy and durability in combat.

- Naval gun mount reinforcements: corrosion‑resistant bars endure marine and recoil forces.

Heavy Machinery Equipment

Outstanding load capacity and toughness allow 7A04 to excel in demanding industrial machinery roles.

- Hydraulic excavator booms and arm sections: bars withstand bending moments and abrasive forces.

- Crane jib and tower sections: high strength enables lifting of massive loads safely.

- Press machine frames and dies: rigid bars maintain shape and precision under extreme forces.

Why Choose Us?

- Price Advantage: We support both retail and bulk purchases for metal distributors, offering discounts and rebate policies for B2B customers. Our pricing is transparent, ensuring a competitive advantage with equivalent-quality aluminum bars.

- Fast Delivery: With thousands of tons of stock available, standard sizes can be matched directly from our existing inventory, ensuring rapid shipment. Our advanced equipment and professional team help shorten delivery times and provide convenient logistics, ensuring on-time delivery.

- High-Quality Products: We use high-quality aluminum bar billets and employ precise alloying and heat treatment processes to optimize product strength and ductility. Our uniform cooling and annealing processes ensure high tensile strength and superior performance.

- Excellent Grain Control: Produced via reverse extrusion, we control the cooling rate and homogenization process. Grain ring size is typically controlled to ≤0.5mm, reducing defects and improving material consistency, enhancing product uniformity.

- Comprehensive Quality Testing: We strictly implement multiple inspection processes, including tensile strength, elongation performance, ultrasonic testing, metallographic inspection, etc., ensuring that the aluminum bars meet AMS, EN, NADCAP, and other certification standards.

- Customer Service: We provide comprehensive after-sales service to address any customer concerns. Our experienced technical team offers professional consulting and guidance, establishing a robust customer service system to ensure a premium service experience.