7075 T6 Aluminum Round Bar

7075 T6 aluminum round bar is a high-performance cold-worked product made from one of the strongest aluminum alloys available.

The T6 temper denotes a two-step heat treatment process: solution heat treatment (to dissolve alloying elements into solid solution) followed by artificial aging (to precipitate strengthening phases). This results in a round bar with extraordinary tensile and yield strength—outperforming nearly all other aluminum alloys—while maintaining dimensional stability and machinability. Unlike softer aluminum grades, 7075-T6 round bars excel in structural and load-bearing roles, where they resist deformation, fatigue, and stress fractures even under extreme cyclic or static loads.

7075 T6 Aluminum Round Bar Features

Strength-to-Weight Ratio

T6-tempered 7075 delivers tensile strength (~550 MPa) comparable to low-alloy steel but at 1/3 the weight—ideal for weight-sensitive applications like aerospace and EVs.

Peak T6 Temper Performance

Maximizes strength via controlled precipitation hardening, outperforming 6061-T6 (≈310 MPa tensile) and 2024-T3 (≈470 MPa) in structural roles.

Superior Fatigue Resistance

Withstands millions of stress cycles without failure, critical for rotating parts (e.g., shafts) and cyclic-load components (e.g., suspension systems).

Precision Dimensional Control

Tight diameter and straightness tolerances (±0.02mm for small diameters) enable “near-net-shape” machining, reducing waste and production time.

Excellent Machinability

T6 temper allows efficient cutting, drilling, and threading with carbide tools, achieving fine surface finishes (Ra ≤0.8μm) for precision parts.

Temperature Resilience

Maintains 90%+ of room-temperature strength at -40°C and 80%+ at 120°C, suitable for arctic exploration gear and high-heat industrial equipment.

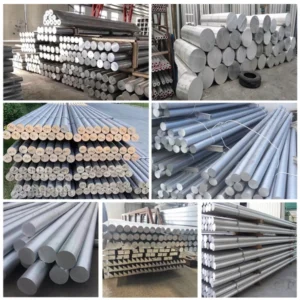

Our 7075-T6 aluminum round bar is manufactured with aerospace and military-grade precision, with strict control over diameter tolerances, straightness, surface finish, and grain structure. Our 7075-T6 aluminum round bars conform to international standards such as ASTM B211, AMS 4126, QQ-A-225/9, and EN 754-2. We can also provide Material Testing Certificates (MTC) and third-party inspection reports upon request.

HSTF is a professional 7075 aluminum round bar manufacturer and supplier in China. We possess a mature supply chain system, advanced equipment, and technology, ensuring our products are highly competitive in terms of cost and price, approximately 5% lower than market prices.

Specification

| Product Name | 7075 T6 Aluminum Round Bar |

| Temper | T6 (solution heat treated + artificially aged for peak strength) |

| Form | Round Bar (solid cylindrical profile) |

| Chemical Composition | Aluminum (90.0–91.4%), Zinc (5.1–6.1%), Magnesium (2.1–2.9%), Copper (1.2–2.0%), Chromium (0.18–0.28%), Iron (≤0.5%), Silicon (≤0.4%), Manganese (≤0.3%), Titanium (≤0.2%), Others (each ≤0.05%, total ≤0.15%) |

| Density | 2.81 g/cm³ (0.101 lb/in³) |

| Diameter Range | 3mm–200mm (standard); 200mm–400mm (custom); miniatures down to 1mm (precision orders) |

| Diameter Tolerance | ±0.02mm–±0.1mm (varies by diameter: e.g., ±0.02mm for Ø3–10mm; ±0.05mm for Ø10–50mm; ±0.1mm for Ø50–200mm) |

| Length Range | 1m–6m (standard); cut-to-length (e.g., 0.5m–12m) or random lengths available |

| Length Tolerance | ±2mm (standard); ±1mm (precision cuts) |

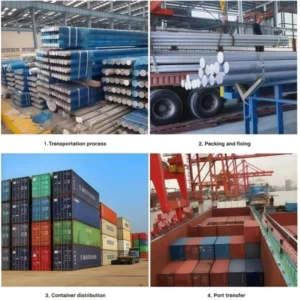

| Package | 1.Inner protection: We wrap each aluminum rod in PE film, with optional paper, cardboard, or foam layers to resist moisture and scratches.

2.Bundle securing: The packaging process bundles and reinforces aluminum rods with steel or PET straps, with protective padding to prevent loosening and abrasion. 3.Outer packaging: We pack bulk orders in sturdy wooden crates or pallets, with optional export-grade fumigation and moisture-proof lining for compression and shock resistance. |

7075 T6 Aluminum Round Bar Mechanical Properties

| Property | Value (Imperial) | Value (Metric) |

| Tensile Strength, Ultimate | 83,000 psi |

572 MPa |

| Tensile Strength, Yield | 73,000 psi | 503 MPa |

| Elongation at Break | 11% |

11% |

| Modulus of Elasticity | 10,400 ksi | 71.7 GPa |

| Shear Strength | 48,000 psi |

331 MPa |

| Brinell Hardness | 150 HB | 150 HB |

| Fatigue Strength | 23,000 psi (at 500 million cycles) |

159 MPa (at 500 million cycles) |

HSTF 7075 T6 T651 Round Bar Stock

| Description | Diameter | Temper | Production Method |

| 7075-T6 Aluminum Round Bar | 0.25″ | T6 | Cold Finish |

| 0.3125″ | T6 | Cold Finish | |

| 0.375″ | T6 | Cold Finish | |

| 7075-T651 Aluminum Round Bar | 0.5″ | T651 | Cold Finish |

| 0.5625″ | T651 | Cold Finish | |

| 0.625″ | T651 | Cold Finish | |

| 0.75″ | T651 | Cold Finish | |

| 0.875″ | T651 | Cold Finish | |

| 1″ | T651 | Cold Finish | |

| 7075-T651 Aluminum Round Bar | 1.125″ | T651 | Cold Finish |

| 1.25″ | T651 | Cold Finish | |

| 1.375″ | T651 | Cold Finish | |

| 1.5″ | T651 | Cold Finish | |

| 1.625″ | T651 | Cold Finish | |

| 1.75″ | T651 | Cold Finish | |

| 7075-T651 Aluminum Round Bar | 1.875″ | T651 | Cold Finish |

| 2″ | T651 | Cold Finish | |

| 2.125″ | T651 | Cold Finish | |

| 2.25″ | T651 | Cold Finish | |

| 2.5″ | T651 | Cold Finish | |

| 2.625″ | T651 | Cold Finish | |

| 7075-T651 Aluminum Round Bar | 2.75″ | T651 | Cold Finish |

| 3″ | T651 | Cold Finish | |

| 3.25″ | T651 | Cold Finish | |

| 3.5″ | T651 | Cold Finish | |

| 3.75″ | T651 | Cold Finish | |

| 4″ | T651 | Cold Finish | |

| 7075-T651 Aluminum Round Bar | 4.25″ | T651 | Cold Finish |

| 4.5″ | T651 | Cold Finish | |

| 4.75″ | T651 | Cold Finish | |

| 5″ | T651 | Cold Finish | |

| 5.5″ | T651 | Cold Finish | |

| 6″ | T651 | Cold Finish |

- Inventory size, quick delivery within 7-10 days.

- Our inventory is updated frequently. If you cannot find the specification you need, please contact us.

Application

Due to its excellent strength-to-weight ratio, 7075-T6 aluminum round bar typically serves in demanding aerospace, high-performance automotive, and military applications. It is also suitable for precision-machined parts, such as gears, shafts, and structural components, where lightweight and high strength are crucial.

| Application Field | Description |

Aerospace |

7075-T6 aluminum round bar is widely used in the aerospace industry, primarily in critical load-bearing components such as aircraft wing beams, landing gear, and fuselage frames. These components endure significant dynamic loads and environmental pressures during flight, so the material must have high strength, lightweight properties, and fatigue resistance. With its exceptional mechanical properties and good structural stability, 7075-T6 aluminum round bar is the preferred material for aerospace structural parts. |

Automotive Industry |

In the automotive industry, 7075-T6 aluminum round bar is commonly used to manufacture chassis, suspension systems, and engine components for high-performance racing cars. These components need to balance lightweight and strength to enhance vehicle handling and acceleration performance. The high strength-to-weight ratio of 7075-T6 aluminum round bar makes it an ideal choice for achieving ultimate performance in the automotive field while effectively reducing overall vehicle weight. |

Defense and Military |

7075-T6 aluminum round bar also plays an important role in the defense and military fields, commonly used in firearm components such as receivers and barrels, as well as some armored structures. Due to its excellent strength and hardness, it can withstand high-impact and high-pressure loads while maintaining material stability. Its fatigue resistance and wear resistance ensure the reliability and long service life of weaponry in harsh environments. |

Industrial Manufacturing |

In industrial manufacturing, 7075-T6 aluminum round bar is commonly used to manufacture shafts, gears, high-stress fasteners, and support components in marine engineering. These parts are often subjected to high loads and complex environments, requiring materials with excellent mechanical properties and some corrosion resistance. The corrosion resistance of 7075-T6 aluminum round bar is not as high as some anti-corrosion alloys. However, the treatment process can significantly improve its performance in harsh environments. This process achieves it. |

Sports |

7075-T6 aluminum round bar is widely used in the sports industry to manufacture bicycle frames and climbing equipment. Due to its high strength and lightweight characteristics, bicycle frames reduce weight while maintaining strength, improving riding efficiency. In climbing equipment, the material’s toughness and impact resistance ensure athlete safety. 7075-T6 aluminum round bar has become the material of choice for many outdoor sports equipment manufacturers. |

Why Choose Us?

Quality Assurance – All products comply with ASTM, AMS, EN, ISO and other international standards, ensuring high purity, uniformstructure, and stable performance.

Professional Supplier – Professional 7075 aluminum bar supplier in China. We have an advanced factory to ensure quality and efficiency.

Competitive Price – The mature supply chain system, advanced equipment and technology ensure that our products are highly competitive in cost and price.

Superior Quality – Quality supervision on whole process of production from raw materials, manufacturing, packaging, warehousing till container loading.

On-Time Delivery – The mature logistics management system and company self owned freight forwarder ensure that our OTD rate reaches 100%.