7075 Aluminum Round Bar

7075 aluminum round bar is a aerospace-grade alloy and one of the strongest aluminum alloys available. They combine exceptional strength, good fatigue resistance, and excellent corrosion resistance, making them ideal for demanding structural applications in the aerospace, defense, automotive, and precision engineering industries. Our 7075 aluminum round bar is manufactured to strict standards, resulting in excellent dimensional consistency, roundness, straightness, and surface quality.

We offer 7075 round bars in various tempering conditions and with different manufacturing processes, among which the most commonly used 7075 T6/T651 aluminum round bar is in stock in full specifications.

HSTF 7075 Aluminum Round Bar Advantages

Exceptional Mechanical Properties

HSTF’s 7075 aluminum rod possess mechanical properties that meet or exceed international standards, excellent machinability, fatigue resistance, and superior high-stress resistance. We can provide material test certificates and third-party inspection reports.

Consistent High Quality

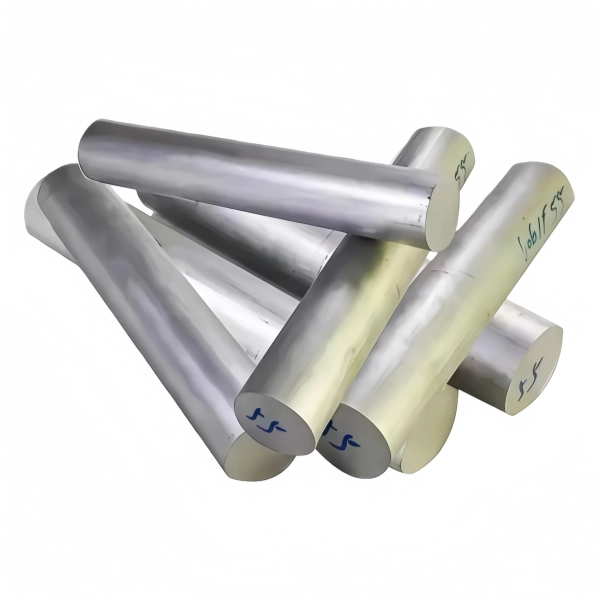

Our 7075 aluminum alloy round bar undergo a unique precision machining process to ensure a flawless surface, free from sand holes, pinholes, horizontal lines, bubbles, impurities, and cracks. Furthermore, they exhibit excellent dimensional consistency, roundness, and straightness to guarantee high product quality.

Standards and Customization

7075 aluminum rod is available in a variety of diameters to meet a wide range of application requirements, from small precision parts to large structural components. Standard and custom diameters can be tailored to specific design needs, allowing for precise control of dimensional tolerances.

Competitive Price

HSTF is a professional 7075 aluminum round bar manufacturer and supplier in China. We possess a mature supply chain system, advanced equipment, and technology, ensuring our products are highly competitive in terms of cost and price, approximately 5% lower than market prices.

Our 7075 aluminum rod conform to international standards such as ASTM B211, ASTM B221, AMS 4123, QQ-A-225/9, and EN 573-3. We also provide Material Testing Certificates (MTC). These documents record chemical composition and mechanical properties. They also include dimensional tolerances. Third-party inspection reports are available upon request. This ensures quality assurance for your critical applications.

HSTF is a professional 7075 aluminum bar manufacturer and supplier in China. We possess a mature supply chain system, advanced equipment, and technology, ensuring our products are highly competitive in terms of cost and price, approximately 5% lower than market prices.

Specification

| Product Name | 7050 Aluminum Round Bar |

| Temper | T6, T651, T7351, T73 |

| Diameter Range | 0.5 inches to 12 inches (custom sizes available) |

| Length | Standard 12 feet or custom cut to size |

| Tolerance | ASTM B221 (±0.005 inches – 0.031 inches, depending on diameter) |

| Surface Finish | Polished, smooth, or anodized |

| Sizes | Round bars come in various diameters (e.g., 1.5 inches, 4 inches, etc.) and lengths |

7075 Aluminum Round Bar Chemical Composition

| Element | Alloy 7075 min | Alloy 7075 max |

| Al | Rem | Rem |

| Si | – | 0.4 |

| Fe | – | 0.5 |

| Cu | 1.2 | 2 |

| Mn | – | 0.3 |

| Mg | 2.1 | 2.9 |

| Cr | 0.18 | 0.28 |

| Zn | 5.1 | 6.1 |

| Ti | – | 0.2 |

| Other Each | – | 0.05 |

| Others Total | – | 0.15 |

HSTF 7075 Aluminum Round Bar Common Size

| Diameter (inches) | Common Length (feet) | Remarks |

| 0.5″ (12.7 mm) | 12′ (Standard), 6′ (Short Cut) | Small size, suitable for precision parts or light structures. |

| 1″ (25.4 mm) | 12′ (Standard), Custom Length | General size, commonly used in machining and tool manufacturing. |

| 2″ (50.8 mm) | 12′ (Standard), Custom Length | Medium-sized structural components, such as shafts or support parts. |

| 3″ (76.2 mm) | 12′ (Standard) | High-load applications, such as aerospace frames. |

| 4″ (101.6 mm) | 12′ (Standard), Custom Length | Heavy-duty industrial parts or large machine components. |

| 6″ (152.4 mm) | 12′ (Standard), Custom Length | Special applications (e.g., military or large molds). |

| 8″ (203.2 mm) | Custom Length (Special Order Required) | Extremely thick sections, for extreme high-stress environments. |

| 10″ (254 mm) | Custom Length (Special Order Required) | Special needs, such as large hydraulic systems or custom equipment. |

| 12″ (304.8 mm) | Custom Length (Special Order Required) | Super-large projects, requires pre-production consultation. |

- Inventory size, quick delivery within 7-10 days.

- Our inventory is updated frequently. If you cannot find the specification you need, please contact us.

Application

7050 Aluminum Round Bar is widely used in high-performance fields, including:

- Aerospace: Aircraft fuselage frames, bulkheads, wing skins, and other structural components where high strength-to-weight ratio and corrosion resistance are critical.

- Military: Missile components, armored vehicles.

- Industrial: Shafts, hydraulic components, high-stress fasteners.

- Automotive: Suspension systems, racing components.

- Sporting goods: Bicycle frames, climbing gear.

- Other industries: High-stress industrial components, precision machinery, and applications requiring excellent machinability and high toughness.

Packaging

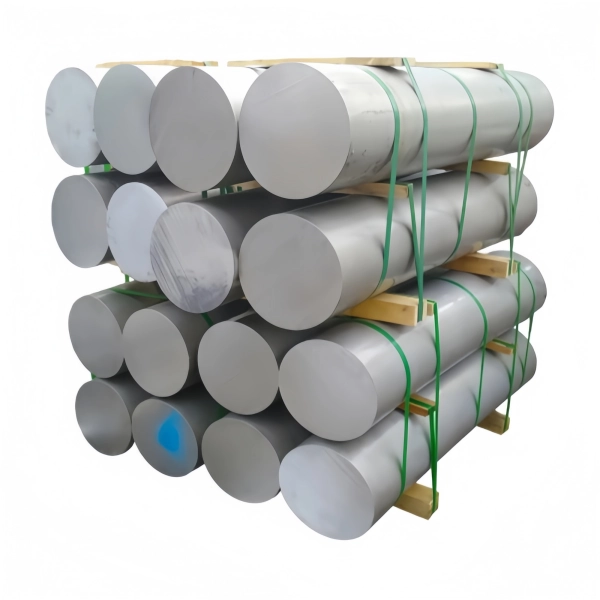

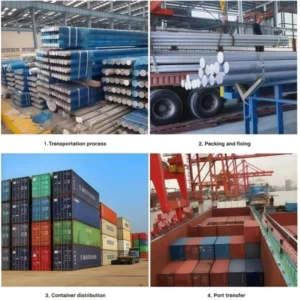

- Inner protection: We wrap each aluminum rod in PE film, with optional paper, cardboard, or foam layers to resist moisture and scratches.

- Bundle securing: The packaging process bundles and reinforces aluminum rods with steel or PET straps, with protective padding to prevent loosening and abrasion.

- Outer packaging: We pack bulk orders in sturdy wooden crates or pallets, with optional export-grade fumigation and moisture-proof lining for compression and shock resistance.

Why Choose Us?

Quality Assurance – All products comply with ASTM, AMS, EN, ISO and other international standards, ensuring high purity, uniformstructure, and stable performance.

Professional Supplier – Professional 7075 aluminum alloy bar supplier in China. We have an advanced factory to ensure quality and efficiency.

Competitive Price – The mature supply chain system, advanced equipment and technology ensure that our products are highly competitive in cost and price.

Superior Quality – Quality supervision on whole process of production from raw materials, manufacturing, packaging, warehousing till container loading.

On-Time Delivery – The mature logistics management system and company self owned freight forwarder ensure that our OTD rate reaches 100%.