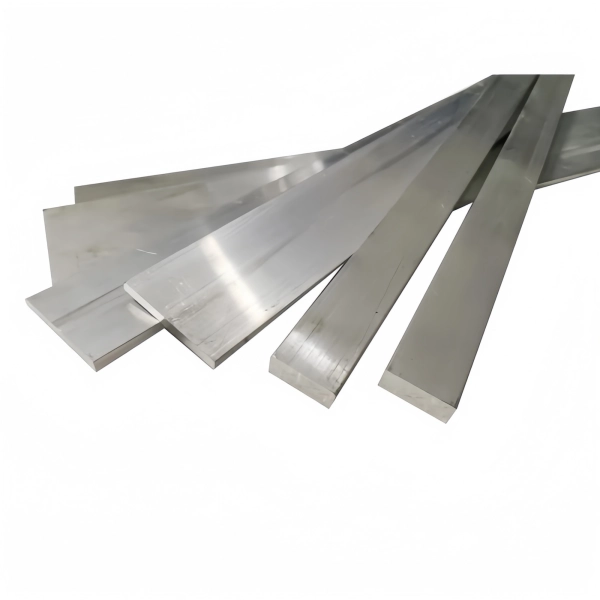

7075 Aluminum Flat Bar

7075 aluminum flat bar is a high-strength aluminum alloy that offers steel-like strength while maintaining the lightweight advantages of aluminum. With excellent fatigue resistance and mechanical stability, it is a preferred material for aerospace structural components, high-performance automotive parts, mold bases, and other high-stress structural applications.

Compared with standard aluminum alloys, the tensile strength of 7075 aluminum flat bars exceeds 540 MPa. Tempers such as T73 and T7351 provide enhanced corrosion resistance, making it suitable for harsh environments such as marine, aerospace, and high-humidity applications.

7075 Aluminum Flat Bar Features

Ultra-High Strength

Tensile strength up to 560 MPa, approaching that of high-strength steels.

Strength-to-Weight Ratio

Offers high strength while being much lighter than steel.

Superior Fatigue Resistance

Stable performance under long-term loading and vibration.

Corrosion Resistance

T6 has low corrosion resistance, but the T73/T73511 tempering treatment significantly improves its resistance to stress corrosion cracking (SCC).

Good Machinability

7075 aluminum alloy is suitable for CNC precision machining; T6511 has higher dimensional stability.

Temperature Resistance

7075 aluminum alloy maintains its properties over a wide temperature range, making it suitable for applications requiring high dimensional stability.

Our 7075 aluminum flat bar conform to international standards such as EN 755, ASTM B221, AMS 4126, AMS 4131, AMS 4141. We also provide Material Testing Certificates (MTC). These documents record chemical composition and mechanical properties. They also include dimensional tolerances. Third-party inspection reports are available upon request. This ensures quality assurance for your critical applications.

HSTF is a professional 7075 aluminum bar manufacturer and supplier in China. We possess a mature supply chain system, advanced equipment, and technology, ensuring our products are highly competitive in terms of cost and price, approximately 5% lower than market prices.

Specification

| Product Name | 7075 Aluminum Flat Bar |

| Thickness | 1/8 inch (0.125 inch) to 2 inches (common), custom sizes available |

| Width | 1/2 inch to 12 inches |

| Length | Standard 12-foot bars, customizable upon request |

| Tolerance | Compliant with ASTM B209 |

| Surface Treatment | Mill finish (extruded), anodized, powder-coated (custom colors), polished, or brushed finish |

| Material | 7075 Aluminum Flat Bar |

| Temper | T6/T651 Cold Finished, T6/T651 Extruded, T7351 Cold Finished |

| Supply Form | Available in full-size bars and custom-cut lengths |

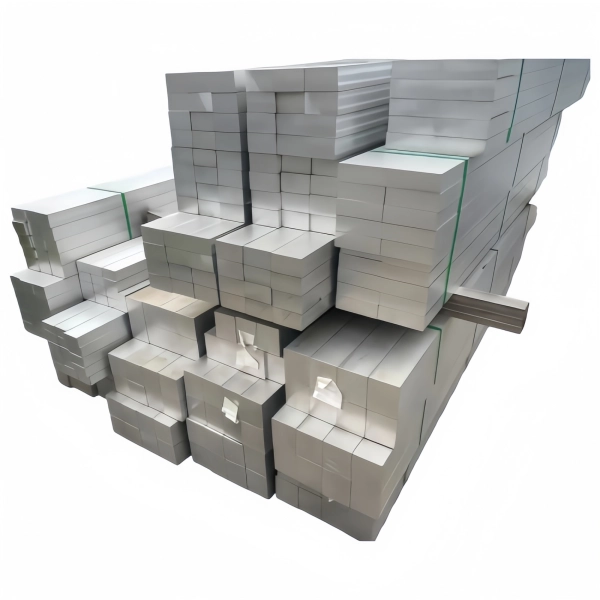

| Package | 1.Inner protection: We wrap each aluminum rod in PE film, with optional paper, cardboard, or foam layers to resist moisture and scratches.

2.Bundle securing: The packaging process bundles and reinforces aluminum rods with steel or PET straps, with protective padding to prevent loosening and abrasion. 3.Outer packaging: We pack bulk orders in sturdy wooden crates or pallets, with optional export-grade fumigation and moisture-proof lining for compression and shock resistance. |

7075 Aluminum Flat Bar Chemical Composition

| Element | Alloy 7075 min | Alloy 7075 max |

| Al | Rem | Rem |

| Si | – | 0.4 |

| Fe | – | 0.5 |

| Cu | 1.2 | 2 |

| Mn | – | 0.3 |

| Mg | 2.1 | 2.9 |

| Cr | 0.18 | 0.28 |

| Zn | 5.1 | 6.1 |

| Ti | – | 0.2 |

| Other Each | – | 0.05 |

| Others Total | – | 0.15 |

HSTF 7075 Aluminum Flat Bar Product

7075 Extruded Aluminum Flat Bar

Temper: 7075-O, 7075-T6510, 7075-T6511, 7075-T73, 7075-T73511

These extruded flat bars offer excellent dimensional stability and low internal stress. They are suited for high-strength structural parts, automotive chassis, rail transit components, and other applications with strict shape requirements.

7075 Cold Finished Aluminium Flat Bar

Temper: 7075-T6, 7075-T651, 7075-T7351

Cold-finished flat bars, processed via cold drawing or cold rolling, have a higher surface finish, tighter tolerances, and more uniform mechanical properties compared to extruded products. They are ideal for precision machining, aerospace fasteners, and defense-grade parts.

7075 Forged Aluminium Flat Bar

Produced through forging, these flat bars have a denser internal structure, superior fatigue resistance, and higher impact toughness. They are widely used in high-load aerospace components, racing chassis, military equipment, and related applications.

HSTF 7075 Aluminum Flat Bar Product

HSTF offers a full range of heat treatment states for 7075 aluminum flat bars, including O, T6, T6511, T73, T73511, T76 —each with unique performance advantages and suitable applications.

7075-O Aluminium Flat Bar

The O state is fully annealed, offering the lowest tensile strength but the best elongation and formability.

7075-T6 Aluminium Flat Bar

The T6 state is achieved through solution heat treatment and artificial aging, reaching maximum strength. It is ideal for high-load and impact-resistant applications.

7075-T6511 Aluminium Flat Bar

The T6511 state is obtained by stretching after T6 heat treatment to eliminate residual stress, providing excellent dimensional stability and rigidity.

7075-T73 Aluminium Flat Bar

The T73 state undergoes extended over-aging, trading some strength for improved corrosion resistance, making it suitable for high-humidity and salt-spray environments.

7075-T73511 Aluminium Flat Bar

T73511 is a variant of T73 that has undergone extrusion and stress relief, resulting in improved corrosion resistance and reduced processing stress in long-term high-humidity applications.

7075-T76 Aluminium Flat Bar

T76 state optimizes the aging process on a T6 base to improve fatigue resistance while maintaining high strength, suitable for applications requiring long fatigue life.

7075 Flat Bar Mechanical Properties by Temper |

|||||

| Temper | Tensile Strength (Ksi) | Tensile Strength (MPa) | Yield Strength (Ksi) | Yield Strength (MPa) | Elongation (%) |

| 7075-O | – | – | 40 | 276 | 10% |

| 7075-T6 | 78 – 81 | 538 – 560 | 70 – 73 | 483 – 503 | 6-7% |

| 7075-T6511 | 78 – 81 | 538 – 560 | 70 – 72 | 483 – 496 | 6-7% |

| 7075-T73 | 65 – 70 | 448 – 483 | 55 – 58 | 379 – 400 | 7-8% |

| 7075-T73511 | 65 – 69 | 448 – 476 | 55 – 59 | 379 – 407 | 7-8% |

| 7075-T76 | 73 – 75 | 503 – 517 | 63 – 65 | 434 – 448 | 7% |

| 7075-T76511 | 74 – 75 | 510 – 517 | 64 – 65 | 441 – 448 | 7% |

If you’re unsure which tempering grade is best for your application, our technical team can help you select the appropriate grade and processing conditions. Contact us for expert advice, data sheets, or custom supply options tailored to your project.

HSTF 7075 Aluminum Flat Bar Stock

| Thickness | 0.25″, 0.375″, 0.5″, 0.625″, 0.75″, 1″, 1.25″, 1.5″, 2″, 2.5″, 4″ |

| Width | 2″, 3″, 1″, 1.5″, 0.75″, 2.5″, 4″, 4.5″, 6″, 3.75″, 3.5″, 1.25″, 5″ |

| Temper | T6, T651, T73511, T7351, T6511 |

| Production Method | Cold Finish- CF, Extruded- EX |

| Specification | Thickness | Width | Production Method |

| 0.25″ x 2″ 7075-T6 Aluminium Flat Bar | 0.25″ | 2″ | CF |

| 0.25″ x 3″ 7075-T6 Aluminium Flat Bar | 0.25″ | 3″ | CF |

| 0.25″ x 1″ 7075-T6 Aluminium Flat Bar | 0.25″ | 1″ | CF |

| 0.25″ x 1.5″ 7075-T6 Aluminium Flat Bar | 0.25″ | 1.5″ | CF |

| 0.375″ x 3″ 7075-T6 Aluminium Flat Bar | 0.375″ | 3″ | CF |

| 0.375″ x 1″ 7075-T6 Aluminium Flat Bar | 0.375″ | 1″ | CF |

0.375″ x 1.5″ 7075-T6 Aluminum Flat Bar |

0.375″ | 1.5″ | CF |

| 0.375″ x 2″ 7075-T6 Aluminium Flat Bar | 0.375″ | 2″ | CF |

| 0.5″ x 1″ 7075-T651 Aluminium Flat Bar | 0.5″ | 1″ | CF |

| 0.5″ x 1.5″ 7075-T651 Aluminium Flat Bar | 0.5″ | 1.5″ | CF |

| 0.5″ x 2″ 7075-T651 Aluminium Flat Bar | 0.5″ | 2″ | CF |

| 0.5″ x 0.75″ 7075-T651 Aluminium Flat Bar | 0.5″ | 0.75″ | CF |

| 0.5″ x 2.5″ 7075-T651 Aluminium Flat Bar | 0.5″ | 2.5″ | CF |

0.5″ x 2″ 7075-T651 Aluminum Flat Bar |

0.5″ | 2″ | EX |

| 0.625″ x 1″ 7075-T73511 Aluminium Flat Bar | 0.625″ | 1″ | EX |

| 0.75″ x 2″ 7075-T651 Aluminum Flat Bar | 0.75″ | 2″ | CF |

| 0.75″ x 2.5″ 7075-T651 Aluminium Flat Bar | 0.75″ | 2.5″ | CF |

| 0.75″ x 3″ 7075-T651 Aluminium Flat Bar | 0.75″ | 3″ | CF |

| 0.75″ x 1″ 7075-T73511 Aluminium Flat Bar | 0.75″ | 1″ | EX |

0.75″ x 1″ 7075-T651 Aluminum Flat Bar |

0.75″ | 1″ | CF |

| 0.75″ x 1.5″ 7075-T651 Aluminium Flat Bar | 0.75″ | 1.5″ | CF |

| 0.75″ x 1″ 7075-T6511 Aluminium Flat Bar | 0.75″ | 1″ | EX |

| 1″ x 2″ 7075-T651 Aluminium Flat Bar | 1″ | 2″ | CF |

| 1″ x 3″ 7075-T651 Aluminium Flat Bar | 1″ | 3″ | CF |

| 1″ x 4″ 7075-T651 Aluminium Flat Bar | 1″ | 4″ | CF |

| 1″ x 1.5″ 7075-T651 Aluminium Flat Bar | 1″ | 1.5″ | CF |

| 1″ x 1.5″ 7075-T73511 Aluminium Flat Bar | 1″ | 1.5″ | EX |

1″ x 2″ 7075-T73511 Aluminium Flat Bar |

1″ | 2″ | EX |

| 1″ x 2.5″ 7075-T651 Aluminium Flat Bar | 1″ | 2.5″ | CF |

| 1″ x 1.25″ 7075-T7351 Aluminium Flat Bar | 1″ | 1.25″ | CF |

| 1″ x 3″ 7075-T6511 Aluminium Flat Bar | 1″ | 3″ | EX |

| 1.25″ x 4″ 7075-T651 Aluminium Flat Bar | 1.25″ | 4″ | CF |

| 1.25″ x 3″ 7075-T651 Aluminium Flat Bar | 1.25″ | 3″ | CF |

| 1.25″ x 2″ 7075-T651 Aluminium Flat Bar | 1.25″ | 2″ | CF |

| 1.25″ x 2.5″ 7075-T651 Aluminium Flat Bar | 1.25″ | 2.5″ | CF |

1.5″ x 3″ 7075-T73511 Aluminum Flat Bar |

1.5″ | 3″ | EX |

| 1.5″ x 2″ 7075-T651 Aluminium Flat Bar | 1.5″ | 2″ | CF |

| 1.5″ x 3″ 7075-T651 Aluminum Flat Bar | 1.5″ | 3″ | CF |

| 1.5″ x 4.5″ 7075-T651 Aluminum Flat Bar | 1.5″ | 4.5″ | CF |

| 1.5″ x 2.5″ 7075-T73511 Aluminum Flat Bar | 1.5″ | 2.5″ | EX |

| 1.5″ x 3″ 7075-T6511 Aluminum Flat Bar | 1.5″ | 3″ | EX |

| 2″ x 3″ 7075-T651 Aluminum Flat Bar | 2″ | 3″ | CF |

2″ x 4″ 7075-T73511 Aluminum Flat Bar |

2″ | 4″ | EX |

| 2″ x 6″ 7075-T73511 Aluminum Flat Bar | 2″ | 6″ | EX |

| 2″ x 3″ 7075-T73511 Aluminum Flat Bar | 2″ | 3″ | EX |

| 2″ x 6″ 7075-T651 Aluminium Flat Bar | 2″ | 6″ | CF |

| 2″ x 4″ 7075-T651 Aluminum Flat Bar | 2″ | 4″ | EX |

| 2.5″ x 4″ 7075-T73511 Aluminum Flat Bar | 2.5″ | 4″ | EX |

| 2.5″ x 3″ 7075-T651 Aluminum Flat Bar | 2.5″ | 3″ | CF |

| 2.5″ x 4″ 7075-T651 Aluminum Flat Bar | 2.5″ | 4″ | CF |

| 2.5″ x 6″ 7075-T7351 Aluminum Flat Bar | 2.5″ | 6″ | CF |

Application

| Application | Description |

Aerospace |

7075 aluminum flat bars are widely used in the aerospace industry for manufacturing various structural components. Their exceptional strength and good corrosion resistance make them ideal for producing wing beams, fuselage frames, and tail structures. The material has low weight. This does not compromise its strength. It ensures stable performance under high load. It also performs well in high-stress environments. This guarantees the aircraft’s structural safety. It also ensures long-term durability. |

Military |

In military applications, 7075 aluminum flat bars are extensively used to produce high-strength and lightweight components, such as structural elements of armored vehicles and other tactical vehicles. Their excellent strength-to-weight ratio enhances armor protection while maintaining a low weight, contributing to improved mobility and durability of military equipment. Additionally, their corrosion resistance ensures reliable performance in harsh environments. |

Automotive |

7075 aluminum flat bars are widely applied in the high-performance automotive sector, particularly for manufacturing frames and suspension components. They effectively reduce weight while enhancing structural strength. These components must withstand significant impact forces, vibrations, and high-speed pressures. The exceptional strength and light weight of 7075 aluminum make it an ideal choice for racing and performance vehicles, improving handling and safety. |

Industrial |

In industrial applications, 7075 aluminum flat bars are commonly used in high-stress machinery, fixtures, and tooling. Due to their superior strength, they provide reliable support for demanding mechanical equipment. Their lightweight properties also facilitate ease of operation and reduce equipment loads. Additionally, the stability and durability of 7075 aluminum flat bars make them a preferred choice for precision industrial manufacturing. |

Sports |

7075 aluminum flat bars are extensively used in sports equipment, including bicycle frames and climbing gear, where high strength is crucial. Their lightweight and durable characteristics allow athletes to reduce unnecessary weight while ensuring durability and stability during activities. The material has excellent impact absorption capability. This ensures sports equipment can withstand external forces. Such forces occur during high-intensity use. This provides safety for athletes. |

Why Choose Us?

Quality Assurance – All products comply with ASTM, AMS, ISO and other international standards, ensuring high purity, uniformstructure, and stable performance.

Professional Supplier – Professional 7075 aluminum alloy bar supplier in China. We have an advanced factory to ensure quality and efficiency.

Competitive Price – The mature supply chain system, advanced equipment and technology ensure that our products are highly competitive in cost and price.

Superior Quality – Quality supervision on whole process of production from raw materials, manufacturing, packaging, warehousing till container loading.

On-Time Delivery – The mature logistics management system and company self owned freight forwarder ensure that our OTD rate reaches 100%.