7075 Aluminum Bar

7075 aluminum bar rod is among the strongest aluminum alloys available, possessing excellent strength-to-weight ratio, good fatigue resistance, and good corrosion resistance. The 7075 aluminum alloy primarily uses zinc as the main alloying element, supplemented with magnesium and copper, allowing it to maintain the lightweight advantages of aluminum alloys while possessing mechanical properties comparable to many types of steel. Therefore, 7075 aluminum alloy rod have become the preferred material in aerospace, defense, and high-performance applications.

7075 Aluminum Alloy Bar Features

High Strength

7075 aluminum rod is one of the strongest aluminum alloys, especially in the T6 tempered state, making it suitable for structural applications with extremely high strength requirements.

Fatigue Resistance

This alloy exhibits excellent resistance to fatigue failure and maintains structural integrity under repeated stress cycles, which is crucial for components subjected to cyclic loads in harsh applications.

Superior High-Stress

7075 aluminum maintains its strength characteristics under significant stress conditions, making it suitable for critical structural applications where reliability under load is paramount.

Excellent Machinability

7075-T651/T7351 aluminum materials have excellent processing performance and can be used to produce precision parts with strict tolerances and excellent surface finish through common processing techniques.

Corrosion Resistance

Although 7075 aluminum alloy has better corrosion resistance than some other high-strength alloys, it is still susceptible to corrosion and may require protective coatings in harsh environments.

Weldability

7075 aluminum alloy is usually not weldable because welding would significantly reduce the strength of 7075 alloy. Therefore, riveting or adhesives and other alternative connection methods are usually adopted.

Our 7075 aluminum bars conform to international standards such as ASTM B211, AMS 4123, QQ-A-225/9, and EN 573-3. We can also provide Material Testing Certificates (MTC) and third-party inspection reports upon request to ensure quality assurance and traceability for your critical applications. We offer a variety of diameters to meet diverse application needs, and provide both standard and custom sizes to meet specific design requirements.

HSTF is a professional 7075 aluminum bar rod manufacturer and supplier in China. We possess a mature supply chain system, advanced equipment, and technology, ensuring our products are highly competitive in terms of cost and price, approximately 5% lower than market prices.

Specification

| Alloy | 7075 |

| Form | Bar (Round, Flat,Square,Hexagonal, and Custom Shapes) |

| Typical Tempers | T6, T651, T73, T7351 |

| Common Diameter Range (Round Bars) | 3mm – 150mm (custom diameters available) |

| Common Side Length Range (Hex/Other Bars) | 5mm – 100mm (custom sizes available) |

| Length | 1m – 6m (or as per customer requirement) |

| Electrical Conductivity | 33% IACS (International Annealed Copper Standard) |

| Thermal Conductivity | 130 – 145 W/m·K (approximately) |

| Melting Range | 475°C – 635°C (885°F – 1175°F) |

| Packaging | Packed in export wooden boxes or wooden pallets, fumigated wooden pallets, and provide fumigation certificates. |

7075 Aluminum Bar Chemical Composition

| Element | Alloy 7075 min | Alloy 7075 max |

| Al | Rem | Rem |

| Si | – | 0.4 |

| Fe | – | 0.5 |

| Cu | 1.2 | 2 |

| Mn | – | 0.3 |

| Mg | 2.1 | 2.9 |

| Cr | 0.18 | 0.28 |

| Zn | 5.1 | 6.1 |

| Ti | – | 0.2 |

| Other Each | – | 0.05 |

| Others Total | – | 0.15 |

HSTF 7075 Aluminum Bar Product

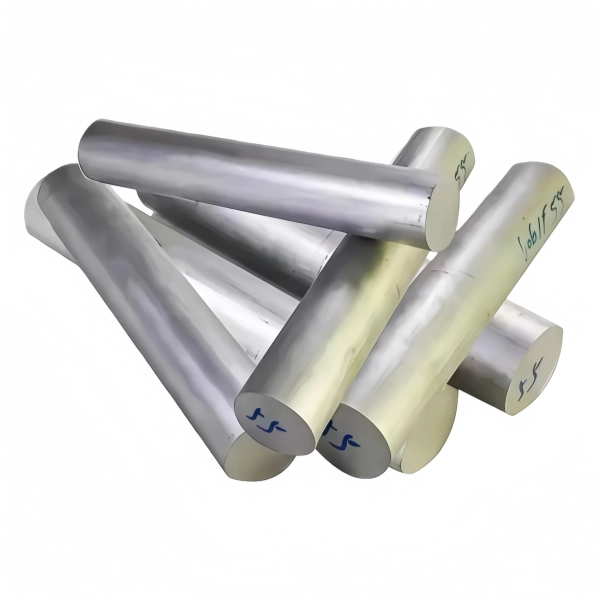

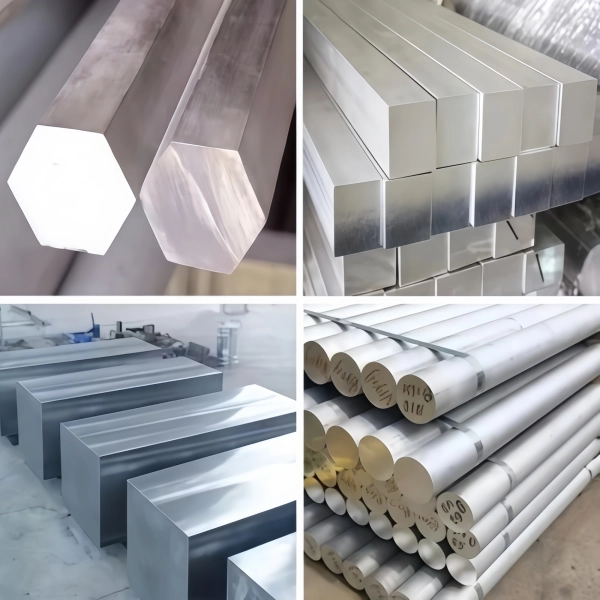

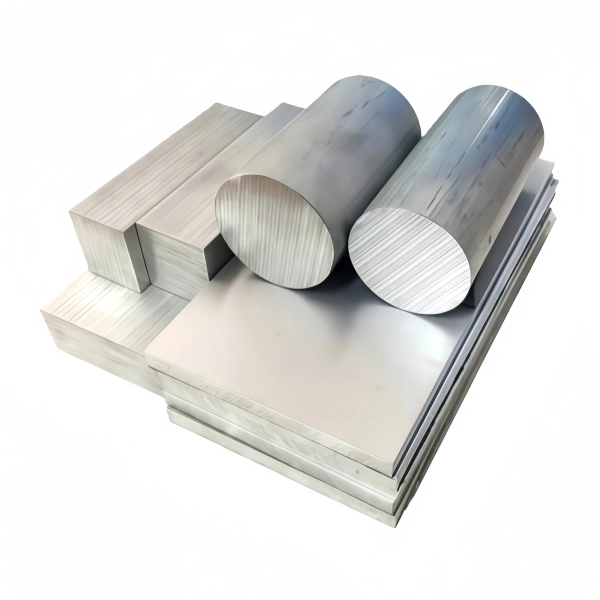

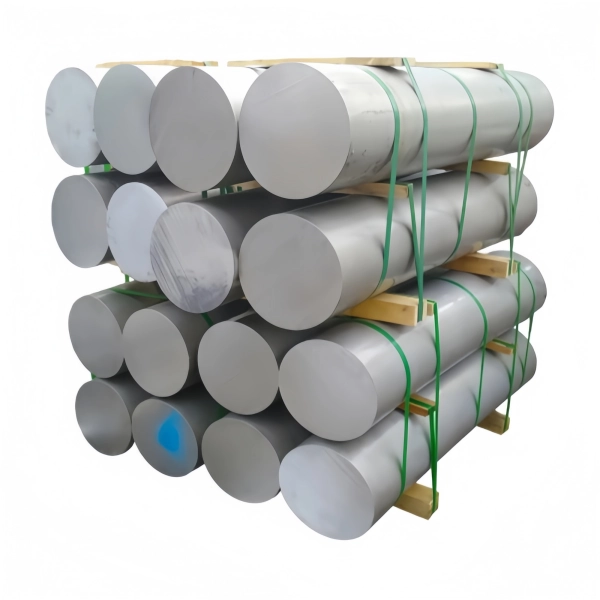

7075 Aluminum Round Bar

Width: Φ5mm – Φ350mm

Available temper: T6, T651, T7351, T73, F

The most widely used form for aerospace and structural applications, offering excellent strength-to-weight ratio, fatigue resistance, and stable machinability.

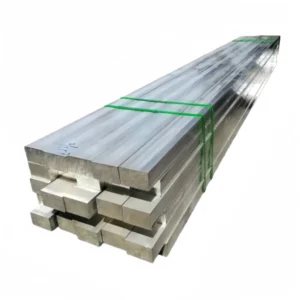

7075 Aluminum Flat Bar

Thickness: 2mm–100mm

Tempers available: T6, T651, T73

High-tensile strength bar ideal for load-bearing frames, jigs, and high-stress components requiring rigidity with light weight.

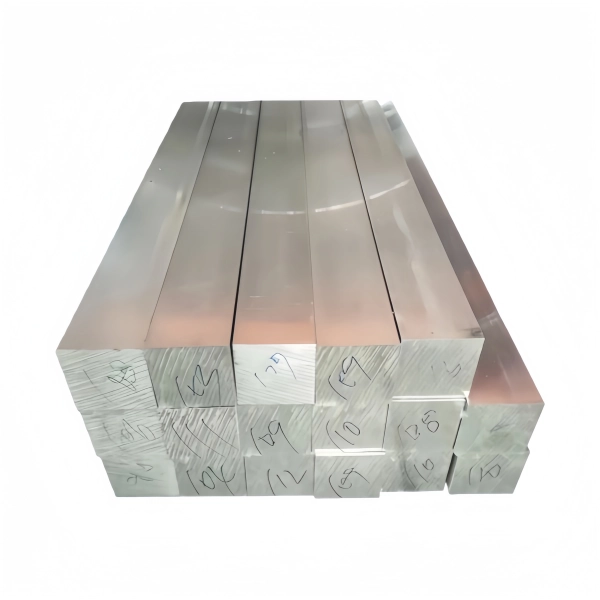

7075 Aluminum Square Bar

Size range: 5×5mm – 200×200mm

Tempers available: T6, T651

Perfect for electronics, fixtures, and precision structures requiring dimensional stability and compressive strength.

7075 Aluminum Hexagon Bar

Across flats: 5mm – 200mm

Tempers available: T6, T651

Preferred for shafts, gears, and fastening components where torsional strength and lightweight performance are critical.

7075 Extruded Aluminum Bar

Available Dimensions: Round bar Ø5mm – Ø350mm, Flat bar 5mm – 100mm thick, up to 6000mm long

Shapes: Round, flat, square, hexagonal (custom extrusions available)

7075 extruded bars provide superior mechanical strength, consistent dimensions, and smoother surfaces. Ideal for aerospace components, automotive chassis, fixtures, and high-performance frames.

7075 Cold Drawn Aluminum Bar

Available Dimensions: Ø5mm – Ø150mm; Square and flat options available

Shapes: Round, square, flat (with fine surface finish and ±0.05mm tolerance)

Cold drawn 7075 bars achieve higher strength and dimensional precision. These are widely used in defense systems, performance tooling, and motion equipment where geometric accuracy is vital.

7075 Forged Aluminum Bar

Available Dimensions: Diameter Ø200mm – Ø1000mm; Lengths up to 5000mm

Shapes: Round forged bar, forged preforms (custom machining available)

Forged 7075 aluminum bars are suitable for critical load-bearing components such as aircraft bearing races, base flanges, and engine mounts. They are ideal for applications requiring high fatigue and stress resistance.

Large Diameter 7075 Aluminum Bar

HSTF specializes in producing extra-large 7075 aluminum bar rod in extrusion, forging, and hot-rolled forms. These bars are designed for heavy-duty, load-bearing, and structurally critical applications in industries such as aerospace, mold making, and transportation systems.

HSTF 7075 Aluminum Bar Rod Temper

7075-T651 / T6511 Aluminum Bar

Most popular temper with excellent strength and dimensional stability. Ideal for precision-machined components and structural parts. Apply in aerospace brackets, structural bars, mold components, machined shafts.

7075-T6 Aluminum Bar

Standard high-strength solution heat-treated and aged alloy. Preferred for general-purpose structural use without stress-relief requirements. Apply in automotive parts, bicycles, sports equipment, tooling.

7075-T7351 / T73511 Aluminum Bar

Stress-relieved and overaged condition for enhanced corrosion resistance, especially in marine or outdoor environments. Apply in aircraft fuselage fittings, marine connectors, industrial fasteners.

7075-T73 Aluminum Bar

The base overaged condition before stress relief. Lower strength than T6 but excellent resistance to stress-corrosion cracking. Appy in naval hardware, defense equipment, heavy-duty connectors.

7075-T76511 Aluminum Bar

Balanced condition offering better toughness and fatigue resistance than T651. Used in parts subject to cyclic stress or vibration. Apply in aircraft landing gear arms, control linkages, suspension components.

7075-T652 Forged Aluminum Bar

High-performance forged temper for critical structural and aerospace applications. Offers enhanced density and mechanical consistency. Apply in aerospace ring segments, pressure-bearing flanges.

7075 Aluminum Bar Rod Mechanical Properties by Temper |

|||||

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Notable Features |

| T651 / T6511 | 572–610 | 503–540 | 11–13 | 150–160 | Excellent dimensional stability and machining performance |

| T6 | 570–610 | 500–540 | 10–11 | 150–160 | Standard strength, good for general use |

| T73 | 500–540 | 420–460 | 13–14 | 130–140 | Improved corrosion resistance, moderate strength |

| T7351 / T73511 | 490–530 | 420–460 | 13–15 | 130–140 | Excellent stress corrosion cracking resistance |

| T76511 | 520–560 | 460–500 | 11–13 | 140–150 | Superior fatigue performance for cyclic load parts |

| T652 (Forged) | 550–590 | 490–530 | 10–12 | 150–165 | Exceptional toughness & density for critical applications |

If you’re unsure which tempering grade is best for your application, our technical team can help you select the appropriate grade and processing conditions. Contact us for expert advice, data sheets, or custom supply options tailored to your project.

Application

7075 Aluminum Alloy Bar for Aerospace

- Airframe components: aircraft frames, wing spars, and other load-bearing parts.

- Engine components: turbine blades and engine mounts.

- Landing gear parts: landing gear struts and shock absorber assemblies.

- Connectors and fasteners: aerospace connectors, bolts, and nuts.

7075 Aluminum Bar for Military Defense

- Airframe components: artillery parts, missile launch tubes.

- Armor structures: tank armor plates and protective structures.

- Military vehicle structural parts: frames and chassis of military vehicles.

- Communication equipment: military antennas and communication equipment mounts.

HSTF 7075 Aluminum Bar for Mold and Tooling

- Mold bases: plastic injection mold cavities and stamping mold cavities.

- Mold cavities: tank armor plates and protective structures.

- Mold accessories: mold support pillars and guide pillars.

- Mold frames: mold frames and frame components.

7075 Aluminum Bar for Automobile Industry

- Body structure components: frames and chassis structures.

- Suspension system parts: suspension brackets and arms.

- Powertrain components: drive shafts and transmission mounts.

- Wheel components: hubs and spokes.

7075 Aluminum Bar for Sports Equipment

- Bicycle components: bike frames and handlebars.

- Climbing gear: trekking poles and climbing protection gear.

- Ski equipment: ski poles and ski binding components.

- Fitness equipment: exercise machine frames and weightlifting gear.

Packaging

- Inner protection: Each aluminum rod is wrapped in PE film, with optional paper, cardboard, or foam layers formoisture and scratch resistance.

- Bundle securing: Aluminum rods are bundled and reinforced with steel or PET straps, with protective padding toprevent loosening and abrasion.

- Outer packaging: Bulk orders are packed in sturdy wooden crates or pallets, with optional export-gradefumigation and moisture-proof lining for compression and shock resistance.

Why Choose Us?

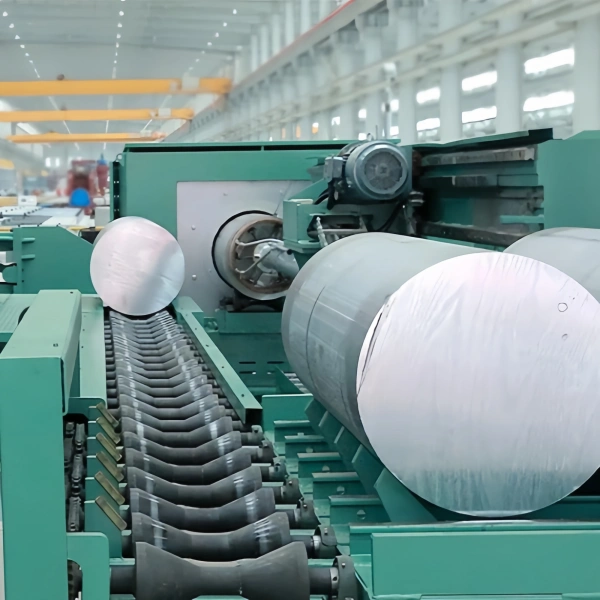

Quality Assurance – All products comply with ASTM, AMS, ISO and other international standards, ensuring high purity, uniformstructure, and stable performance.

Professional Supplier – Professional 7075 aluminum alloy bar rod supplier in China. We have an advanced factory to ensure quality and efficiency.

Competitive Price – The mature supply chain system, advanced equipment and technology ensure that our products are highly competitive in cost and price.

Superior Quality – Quality supervision on whole process of production from raw materials, manufacturing, packaging, warehousing till container loading.

On-Time Delivery – The mature logistics management system and company self owned freight forwarder ensure that our OTD rate reaches 100%.

7075 Aluminum Bar Knowledge Center

HSTF is a professional aluminum bar supplier and manufacturer, and we can provide solutions that will satisfy you. For more information about aluminum alloys, please contact us.

1. Mechanical Properties Comparison (T6 Temper)

|

Alloy Grade |

Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Density (g/cm³) |

| 572 | 503 | 11% | ≥150 | 2.81 | |

| 7050-T7451 | 524 | 469 | 11% | 135 |

2.83 |

|

7050-T7651 |

552 | 490 | 11% | 135 | 2.83 |

| 7A04-T6 | ≥530 | ≥400 | ≥5% | – |

– |

- 7075 has the highest strength; 7050 can approach 7075 strength with T7651 treatment; 7A04 has similar strength to 7050 but lower elongation.

2. Corrosion Resistance Comparison

- 7A04 Alloy: Lower stability; susceptible to stress corrosion cracking; inferior corrosion resistance compared to 7075 and 7050.

- 7050 Alloy: Excellent stress corrosion cracking (SCC) resistance; performs stably in humid and marine environments via T7451/T7651 overaging; first choice for aerospace applications.

- 7075 Alloy: Susceptible to SCC in T6 temper, especially in the short transverse direction; prone to intergranular cracking; requires cladding or other protective treatments.

3. Stress Corrosion Cracking (SCC) Resistance

- 7050: Excellent; overaging (T74/T76/T77) treatments precipitate and stabilize strengthening phases at grain boundaries, dramatically improving SCC resistance.

- 7075: Poor; highly sensitive to SCC in high-strength tempers (especially T6), a major weakness.

- 7A04: Prone to stress corrosion cracking; less resistant than 7075.

4. Weldability

- All three alloys have limited weldability. 7075 and 7050 are not recommended for fusion welding unless post-weld heat treatment is applied. 7A04 has good spot weldability but poor gas weldability.

5. Selection Guidelines

- Maximum Static Strength: Choose 7075-T651; lower cost, suitable for dry, non-corrosive environments.

- High SCC Environments: Must choose 7050-T7451/T7651; higher cost but excellent SCC resistance; ideal for aerospace and marine engineering.

- Aerospace Structures: 7A04 is mature and reliable, with strength comparable to 7050 but lower corrosion resistance.

7050 is a comprehensive upgrade of 7075 in terms of reliability, safety, and overall performance, addressing 7075’s critical SCC weakness. Although more expensive, this “reliability premium” is essential for modern high-end equipment manufacturing. 7A04 remains widely used in aerospace as a mature alloy, but with inferior corrosion resistance compared to 7050.

Both 2024 and 7075 are high-strength materials commonly used in aerospace and high-stress structural applications. They also offer excellent machinability, making them suitable for manufacturing precision parts. However, they differ slightly in composition, properties, and applications:

- 7075 primarily contains zinc as its main alloying element, while 2024 primarily contains copper.

- 7075 has better corrosion resistance, whereas 2024 exhibits weaker corrosion resistance.

- 7075 offers higher fatigue strength, making it suitable for applications requiring high fatigue performance. 2024 has relatively lower fatigue strength.

- 7075 is commonly used in high-strength and high-fatigue-strength applications, such as aerospace structural components. 2024 is often used in parts requiring high strength and good machinability, such as aircraft frames and aerospace components.

Both 6061 and 7075 are widely used in industries such as aerospace and automotive. They both possess excellent machinability and are easy to cut and process. However, there are some subtle differences in their composition and properties:

- 7075 primarily consists of zinc as its alloying element, whereas 6061 primarily contains magnesium and silicon.

- 7075 has higher strength, making it more suitable for high-stress applications, while 6061 has lower strength but maintains a good balance between strength and toughness.

- 6061 offers better corrosion resistance than 7075, especially in marine environments.

- 6061 has better weldability compared to 7075, making it more suitable for structural applications that