7005 Aluminum Rod Bar

7005 aluminum rod bar is a heat-treatable Al-Zn-Mg alloy that combines high strength, good weldability, and lightweight properties. It is widely used in welded structures requiring high strength and fracture toughness, such as trusses, struts, and containers in transport vehicles, as well as large heat exchangers and sporting equipment like tennis rackets and baseball bats.

The grade of 7075 alloy is AA 7005 / UNS A97005, listed as GB 7005 in Chinese standards and JIS 7N11 in Japanese standards. Common tempers include T1, T3, T4, T5, 7005-T6, and T8, with T6 often used for structural applications. This alloy is typically supplied in a rolled finish condition, and anodizing and coating treatments are available for enhanced surface protection or improved appearance.

HSTF 7005 Aluminum Bar Advantages

Exceptional Strength-to-Weight Ratio

As a heat-treatable 7xxx-series alloy, 7005 delivers high mechanical strength—typical T6 temper offers ultimate tensile strength (UTS) of 524–560 MPa and yield strength (YS) of 455–480 MPa—while maintaining aluminum’s low density (~2.78 g/cm³). This makes it ideal for weight-sensitive applications (e.g., bicycle frames, truck components) where structural integrity without excess mass is critical.

Superior Weldability

Unlike many high-strength 7xxx alloys. 7005 has a copper content near or below 0.2%, enabling reliable resistance welding (a common method for structural assemblies). While fusion welding requires careful process control, its weldability outperforms higher-copper 7xxx counterparts, making it a preferred choice for joined load-bearing parts.

Excellent Machinability and Surface Finish Compatibility

7005 machines cleanly with good tool life and minimal burring, supporting efficient production of precision components. It also responds exceptionally well to anodizing and polishing, allowing for durable, corrosion-resistant surfaces that meet aesthetic or functional requirements (e.g., sports equipment, automotive trim).

Balanced Corrosion Resistance and Toughness

It offers solid general corrosion resistance and, in certain tempers (e.g., T73/T76), improved resistance to stress-corrosion cracking (SCC) and exfoliation. Combined with decent elongation (~10–11% in 7005-T6), this balance of toughness and corrosion performance ensures reliability in demanding environments (e.g., outdoor machinery, marine components).

Our 7005 aluminum rod conform to international standards such as ASTM B221, EN 755, EN 573, and ISO 9001. We also provide Material Testing Certificates (MTC). These documents record chemical composition and mechanical properties. They also include dimensional tolerances. Third-party inspection reports are available upon request. This ensures quality assurance for your critical applications.

HSTF is a professional aluminum rod bar manufacturer and supplier in China. We possess a mature supply chain system, advanced equipment, and technology, ensuring our products are highly competitive in terms of cost and price, approximately 5% lower than market prices.

Specification

| Product Name | 7005 Aluminum Bar |

| Temper | T5, T53, 7005-T6 |

| Equivalent Name | AA 7005 / UNS A97005 / EN AW‑7005 / JIS 7N11 |

| Length | 1–6 m standard; cut‑to‑length available |

| Surface Finish | Polished, smooth, or anodized |

| Shape | Round, Square, Hexagonal, Flat, Rectangular |

7005 Aluminum Bar Chemical Composition

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others (Each) | Others (Total) |

| 0.35 | 0.40 | 0.10 | 0.2-0.7 | 1.0-1.8 | 0.06-0.20 | 4.0-5.0 | 0.01-0.06 | 0.05 | 0.15 |

7005 Aluminum Bar Properties

| Properties | Value | Properties | Value |

| Density | 2.78 g/cm³ | Tensile strength Rm/Mpa | 340-350 |

| Melting Point | 610 – 640°C | Yield strength Rp0.2/Mpa | 270-290 |

| Thermal Conductivity | 160 W/m·K | Elongation | 8-10% |

| Coefficient of Thermal Expansion | 23.1 µm/m·°C | Hardness | 110 |

| Electrical Conductivity | 33 % IACS | – | – |

HSTF 7005 Aluminum Bar Products

7005 T5 Aluminum Bar

7005 T5 aluminum bars undergo artificial aging treatment, resulting in high strength and excellent dimensional stability. They are commonly used in structural components requiring high strength and good machinability, with typical applications including transport vehicle trusses, struts, containers, large heat exchangers, and sporting equipment such as tennis rackets and baseball bats.

7005 T53 Aluminum Bar

The T53 temper is a specific heat-treated condition for 7005 aluminum, offering high fatigue strength (170 MPa) and a solid strength-to-weight ratio, with a tensile strength reaching up to 390 MPa. Although it has lower ductility, its strength and fatigue resistance make it ideal for applications with high stress and repetitive loads, such as sports equipment and structural components.

7005 T6 Aluminum Bar

7005 T6 aluminum is one of the most common heat-treated variations of this alloy. The “T6” temper is a hardening process that enhances mechanical properties for greater strength and durability, making it especially suitable for applications where improved strength is essential, such as bicycle frames and sports equipment made from 7005 aluminum alloy.

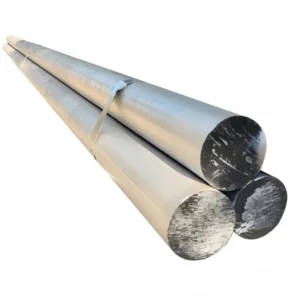

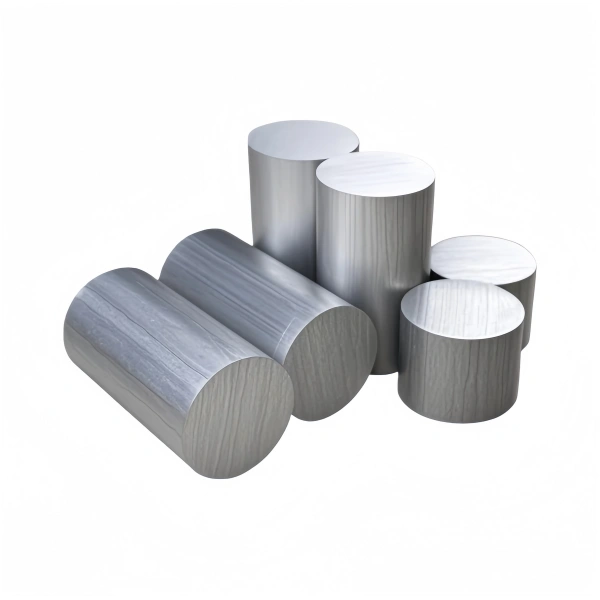

7005 Aluminum Round Bar

The 7005 aluminum round bar offers exceptional strength and fatigue resistance, making it widely used in high-load-bearing structures. Its excellent corrosion resistance and weldability make it suitable for outdoor and harsh environments.

| Description | Diameter (in) | Diameter (mm) |

| 7005 Aluminium Round Bar | 0.75″ | 19.05 |

| 7005 Aluminium Round Bar | 1.0″ | 25.4 |

| 7005 Aluminium Round Bar | 1.25″ | 31.75 |

| 7005 Aluminium Round Bar | 1.5″ | 38.1 |

| 7005 Aluminium Round Bar | 1.75″ | 44.45 |

| 7005 Aluminium Round Bar | 2.0″ | 50.8 |

| 7005 Aluminium Round Bar | 2.25″ | 57.15 |

| 7005 Aluminium Round Bar | 2.5″ | 63.5 |

| 7005 Aluminum Round Bar | 2.75″ | 69.85 |

| 7005 Aluminum Round Bar | 3.0″ | 76.2 |

| 7005 Aluminum Round Bar | 3.5″ | 88.9 |

| 7005 Aluminum Round Bar | 4.0″ | 101.6 |

| 7005 Aluminum Round Bar | 5.0″ | 127 |

| 7005 Aluminum Round Bar | 6.0″ | 152.4 |

7005 Aluminum Flat Bar

Size: 5-200mm

Known for its high strength and lightweight properties, the 7005 aluminum flat bar is ideal for use in construction and machinery manufacturing where flat support and frame structures are needed. Its superior fatigue resistance and machinability make it a top choice for a wide range of industrial applications.

| Description | Thickness (mm) | Width (mm) |

| 7005 Aluminium Flat Bar | 5 | 10/20/30/40 |

| 7005 Aluminium Flat Bar | 10 | 20/30/40/50/60 |

| 7005 Aluminium Flat Bar | 15 | 20/30/40/50/60 |

| 7005 Aluminium Flat Bar | 20 | 30/40/50/60/70 |

| 7005 Aluminium Flat Bar | 30 | 40/50/60/70/80 |

| 7005 Aluminium Flat Bar | 40 | 50/60/70/80/90 |

| 7005 Aluminium Flat Bar | 50 | 60/70/80/90/100 |

| 7005 Aluminium Flat Bar | 60 | 70/80/90/100/110 |

| 7005 Aluminium Flat Bar | 70 | 80/90/100/110/120 |

| 7005 Aluminium Flat Bar | 80 | 90/100/110/120/130 |

| 7005 Aluminium Flat Bar | 90 | 100/110/120/130/140 |

| 7005 Aluminium Flat Bar | 100 | 110/120/130/140/150 |

| 7005 Aluminium Flat Bar | 110 | 120/130/140/150/160 |

| 7005 Aluminium Flat Bar | 120 | 130/140/150/160/170 |

Application

Bicycle Manufacturing

Due to its high strength, corrosion resistance, and lightweight properties. 7005 aluminum alloy is the preferred choice for high-end bicycle brands like Motobecane and Kinesis. Frames and beams made from 7005 aluminum provide excellent impact resistance, delivering a superior riding experience on rough terrain.

Outdoor Sports Equipment

In outdoor sports, 7005 aluminum alloy stands out for its strength-to-weight ratio and weldability. Beyond bike frames, it serves for aluminum tent poles, tennis rackets, softball bats, golf clubs, and trekking poles.

Automotive Industry

With its strength, lightweight nature, and corrosion resistance. 7005 aluminum finds wide application in transportation for trusses, rods, support structures, automotive crash beams, truck reinforcements, trailers, containers, and rapid transit vehicles. This improves vehicle stability, transport efficiency, and fuel economy.

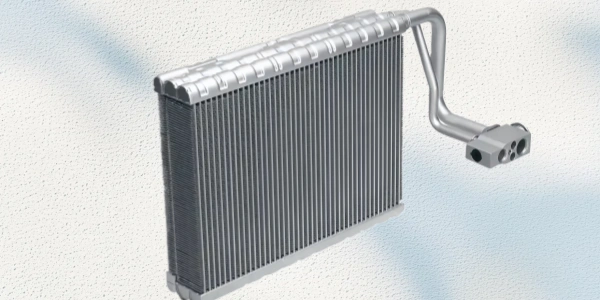

Large Heat Sinks

7005 aluminum is well-suited for medium-strength, high-toughness large heat sinks and heat exchanger components. Particularly where post-weld heat treatment is not possible. Its natural strength and corrosion resistance make it ideal for high-temperature, high-stress parts, ensuring heat dissipation efficiency and durability.

Packaging

- Inner protection: We wrap each aluminum rod in PE film, with optional paper, cardboard, or foam layers to resist moisture and scratches.

- Bundle securing: The packaging process bundles and reinforces aluminum rods with steel or PET straps, with protective padding to prevent loosening and abrasion.

- Outer packaging: We pack bulk orders in sturdy wooden crates or pallets, with optional export-grade fumigation and moisture-proof lining for compression and shock resistance.

Why Choose Us?

Quality Assurance – All products comply with ASTM, EN, ISO and other international standards, ensuring high purity, uniformstructure, and stable performance.

Professional Supplier – Professional 7005 aluminum alloy bar supplier in China. We have an advanced factory to ensure quality and efficiency.

Competitive Price – The mature supply chain system, advanced equipment and technology ensure that our products are highly competitive in cost and price.

Superior Quality – Quality supervision on whole process of production from raw materials, manufacturing, packaging, warehousing till container loading.

On-Time Delivery – The mature logistics management system and company self owned freight forwarder ensure that our OTD rate reaches 100%.

Compared with Other Alloys

7005 vs 7075

| Properties | 7005 | 7075 |

| Main Alloying Elements | Zinc (Zn), Magnesium (Mg) | Zinc (Zn), Magnesium (Mg), Copper (Cu) |

| Tensile Strength | 290-350 MPa | 510-600 MPa |

| Weldability | Excellent | Poor |

| Processability | Good | Difficult |

| Corrosion Resistance | Excellent | Poor |

| Density | 2.78 g/cm³ | 2.81 g/cm³ |

| Hardness | 94 | 150 |

- Strength/Weldability: 7075 aluminum is stronger but has lower weldability, prone to cracking. 7005 aluminum offers excellent weldability while maintaining high strength, ideal for applications requiring strong welded connections like bicycle frames.

- Machinability: 7075 aluminum has higher hardness, making it challenging to machine, whereas 7005 aluminum offers better machinability for complex profile designs.

- Corrosion Resistance: 7005 aluminum is more corrosion-resistant, suitable for outdoor and humid environments, while 7075 performs poorly in corrosive settings.

- Cost: With lower zinc content, 7005 aluminum is more affordable, providing a cost advantage over 7075.

In summary, 7075 aluminum excels in extreme high-stress environments with its superior strength and hardness but lacks in weldability and corrosion resistance. 7005 aluminum is favored for lightweight applications with its weldability, corrosion resistance, and cost-efficiency, particularly in bicycle frames and building structures.

7005 vs 6061

| Properties | 7005 | 6061 |

| Main alloying elements | Zinc (Zn), Magnesium (Mg) | Magnesium (Mg), Silicon (Si) |

| Tensile strength | 290-350 MPa | 240-310 MPa |

| Weldability | Good | Excellent |

| Processability | Difficult | Excellent |

| Corrosion resistance | Excellent | Fine |

- Strength: 7005 aluminum has greater strength, ideal for applications requiring high load-bearing, such as bicycle frames and heavy transport equipment. 6061 aluminum provides adequate strength for many industrial uses.

- Weldability & Machinability: With magnesium and silicon content, 6061 aluminum offers superior weldability and machinability. Although 7005 aluminum requires post-weld heat treatment for strength recovery, it welds better than 7075.

- Lightweight Design: 7005 aluminum’s high strength allows for thinner tubing, making it excellent for weight-sensitive designs like bike frames. While heavier, 6061 aluminum has a good strength-to-weight ratio for general industrial use.

- Cost: 7005 aluminum has higher production costs due to zinc content and processing complexity, whereas 6061 aluminum is cost-effective for high-volume industrial production.

In conclusion, 7005 aluminum outperforms in strength and lightweight design but has higher processing costs, suitable for high-strength, high-load applications. 6061 aluminum offers versatility with excellent machinability and lower costs, commonly used in construction and industrial equipment.