6082 Aluminum Round Bar

6082 aluminum round bar is the strongest material in the 6000 series, often referred to as a “structural alloy.” It contains magnesium, manganese, and silicon, which enhance its mechanical strength and corrosion resistance while maintaining good machinability and weldability. The T6 and T651 tempers exhibit excellent strength and machinability, making them ideal for processes like turning, milling, drilling, threading, and welding.

6082 aluminum is commonly made by extrusion and rolling, although it is generally not used for casting as a forged alloy. It cannot be work-hardened, but strength can be increased through heat treatment, though this lowers ductility. It is used in high-stress applications such as trusses, bridges, cranes, and other structural engineering projects.

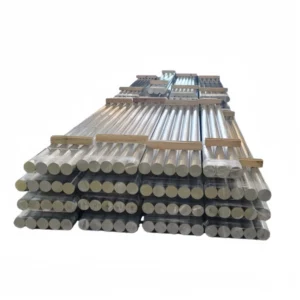

HSTF offers custom production processes for 6082 aluminum rod according to customer requirements, including extruded bars, cold-worked bars, and forged aluminum bars. Specific size ranges are listed below:

Extrusion Aluminum Round Bar

- Temper: O,T4, T5, T6,T66

- DIA: 0.4″-16″(10-420mm)

- Spec: BS HE30, EN 2326

- Extruded Rod Size Chart

Cold Finished Aluminum Round Bar

- Temper: O, T4, T6,T66

- DIA: 0.125″-8″(3-200mm)

- Spec: EN 754

- Cold Finished Rod Size Chart

Forged Aluminum Round Bar

- Temper: 7.8″-40″(200-1000mm)

- Extremely High Strength

- Excellent Fatigue Resistance

- Excellent Heat Resistance.

Our 6082 aluminum alloy rod conforms to international standards. These include EN573-3, BS EN 755-2, and ASTM B221. It also meets AMS 4156, ASTM B209, and EN485. Furthermore, it conforms to AMS QQ-A-200/9. We can also provide Material Testing Certificates (MTC). Third-party inspection reports are available upon request. This ensures quality assurance for your critical applications. It also provides traceability. Our 6082 aluminum alloy rod is available in various diameters. This meets different application needs. Both standard and custom sizes are available. They meet specific design requirements.

Specification

| Alloy | 6082 |

| Equivalent Name | HE30 ,AA6082,H30TF,DIN 3.2315,EN AW-6082,A96082,AlMgSi1 |

| Temper | T4, T6, T651, T6511, O |

| Length | 1-6m, Random, Fix & Cut Length or as per clients’ requirement |

| Surface | Bright, Polish & Black |

| Production Process | Cold finish, Extruded, Forged |

| Standard | UNS A96082,EN573-3,BS EN 755-2,ASTM B221,AMS 4156,ASTM B209,EN485,AMS 4156,AMS QQ-A-200/9 |

6082 Aluminum Round Bar Chemical Composition

| Element | EN AW-6082 |

| Si | 0.7-1.3 |

| Fe | 0.5 |

| Cu | 0.1 |

| Mn | 0.4-1.0 |

| Mg | 0.6-1.2 |

| Cr | 0.25 |

| Zn | 0.2 |

| Ti | 0.1 |

| Others (Total) | 0.15 |

| Al | Rem |

6082 Aluminum Round Bar Physical Properties

| Physical Property | Value |

| Density | 2.70 g/cm³ |

| Melting Point | 555℃ |

| Thermal Expansion | 24×10^-6 /K |

| Modulus of Elasticity | 70GPa |

| Thermal Conductivity | 180 W/m.K |

| Electrical Resistivity | 0.038 x10^-6Ω.m |

HSTF 6082 Aluminum Rod Temper

6082 T6 Aluminum Round Bar

The 6082-T6 aluminum bar undergoes solution heat treatment and artificial aging, resulting in high strength and excellent machinability. It is suitable for applications requiring strength and cutting performance. When machining, it is recommended to use chip breakers to improve chip formation. However, due to quenching limitations, some thin-walled profiles may not be available in the T6 condition.

6082 T651 Aluminum Round Bar

The 6082-T651 aluminum bar undergoes solution heat treatment, stress relief, and artificial aging, providing high strength and excellent machining performance. Chip breakers can be used during machining to cut the metal chips into small segments, preventing tangling and improving efficiency. It is ideal for high-strength, precision-machined components, such as those in aerospace and high-stress applications.

6082 T6511 Aluminum Round Bar

6082-T6511 aluminum bar undergoes solution heat treatment, stress relief, and artificial aging, offering high strength and excellent machinability. Compared to the T6 condition, the stress-relief process in T6511 improves material stability and machining consistency, reducing the risk of deformation. It is suitable for applications requiring high precision and strength, such as aerospace and structural components.

6082 T4 Aluminum Round Bar

The 6082-T4 aluminum bar undergoes solution heat treatment and is naturally aged to a stable state, providing good formability, and making it suitable for bending and forming applications. In the T4 condition, it offers medium strength and high ductility and is commonly used for products that do not require cold working.

6082 O Aluminum Round Bar

6082 O aluminum bar is in a fully annealed state, offering maximum ductility and excellent forming properties, making it ideal for applications that require complex bending and forming. However, due to its lower strength, the machinability of O-temper 6082 is poor, and it is not suitable for high-stress or high-strength requirements.

HSTF 6082 Aluminum Rod Size

| 6082 Extruded Aluminum Round Bar | |||||

| 1/2″ | 1-5/8″ | 3-1/2″ | 9/16″ | 1-3/4″ | 3-5/8″ |

| 5/8″ | 1-7/8″ | 3-3/4″ | 11/16″ | 2″ | 4″ |

| 3/4″ | 2-1/8″ | 4-1/2″ | 13/16″ | 2-1/4″ | 5″ |

| 7/8″ | 2-3/8″ | 6″ | 15/16″ | 2-1/2″ | 7″ |

| 1″ | 2-5/8″ | 8″ | 1-1/8″ | 2-3/4″ | 10″ |

| 1-1/4″ | 3″ | 12″ | 1-5/16″ | 3-1/4″ | 14″ |

| 1-1/2″ | 3-3/8″ | 16″ | |||

| 6082 Cold Finish Aluminum Round Bar | |||||

| 1/2″ | 1-1/2″ | 3-1/4″ | 9/16″ | 1-5/8″ | 3-3/8″ |

| 5/8″ | 1-3/4″ | 3-1/2″ | 11/16″ | 1-7/8″ | 3-5/8″ |

| 3/4″ | 2″ | 3-3/4″ | 13/16″ | 2-1/8″ | 4″ |

| 7/8″ | 2-1/4″ | 4-1/2″ | 15/16″ | 2-3/8″ | 5″ |

| 1″ | 2-1/2″ | 5-1/2″ | 1-1/8″ | 2-5/8″ | 6″ |

| 1-1/4″ | 2-3/4″ | 7″ | 1-5/16″ | 3″ | 8″ |

In addition to standard round bars, HSTF also supplies a variety of other shapes of 6082 aluminum, such as square bars, flat bars, and hexagonal bars. If you require other profiles or custom specifications, please feel free to contact our team to find a solution suitable for your project.

Application

6082 Round Bar for Structural Engineering

High strength and excellent weldability make it ideal for load‑bearing frameworks in buildings and bridges.

- Truss and beam members: strong bars provide reliable support in roof and floor structures.

- Bridge girders and connectors: corrosion‑resistant bars ensure durability in harsh outdoor conditions.

- Scaffolding and modular frameworks: lightweight yet sturdy bars simplify assembly and transport.

6082 Round Bar for Transportation and Automotive

Combines strength with light weight for improved performance and fuel efficiency in vehicles.

- Truck chassis and trailer frames: tough bars handle heavy loads with reduced vehicle mass.

- Railway carriage structures: strong bars enhance safety and longevity in rolling stock.

- Suspension components: fatigue‑resistant bars maintain performance under dynamic stresses.

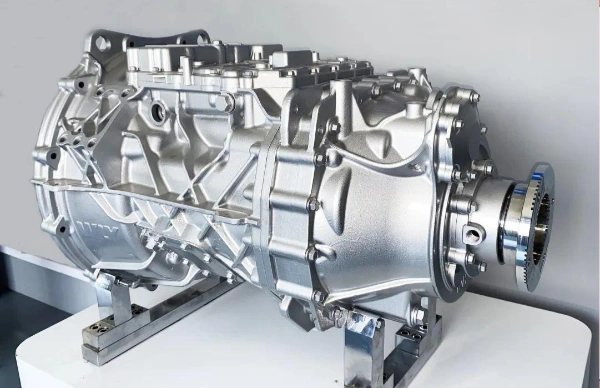

6082 Round Bar for Machinery Equipment

Good machinability and mechanical properties support robust, precise industrial parts.

- Machine tool bases and frames: rigid bars provide stability and vibration damping.

- Gearbox and transmission housings: strong bars endure mechanical stress and wear.

- Robotic arm components: lightweight bars improve speed and reduce actuator loads.

6082 Round Bar for Marine Industry

Superior corrosion resistance in seawater makes it suitable for marine structures and fittings.

- Hull stiffeners and deck supports: bars retain strength and resist saltwater degradation.

- Boat mast and rigging bases: durable bars withstand cyclic loads and marine exposure.

- Offshore platform brackets: high strength ensures safety in harsh offshore environments.

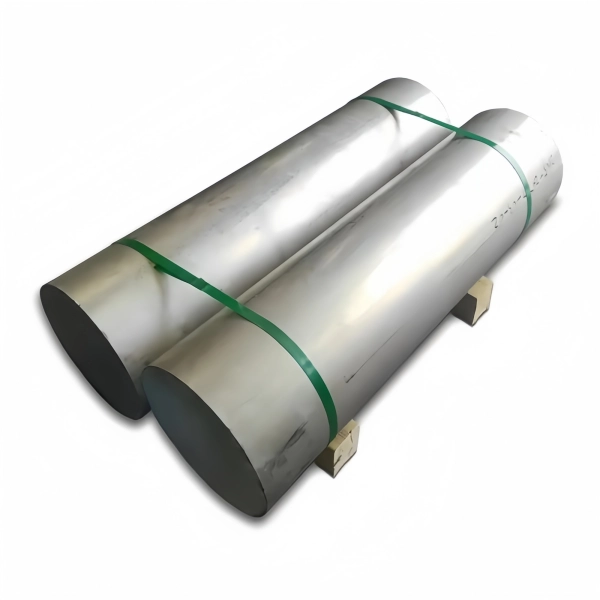

Package

| Packing | 1,Generaally package:Anti-water paper+strapped with min three strapping strips. |

| 2,Standard exporting package:Anti-water paper and plastic+covered by iron shrrt+strapped with min three strapping strips. | |

| 3,Excellent package:Anti-water paper and plastic film+covered by iron sheet+strapped with min three strapping strip+fixed on the iron or wooden pallets by strapping strips. | |

| Shipping | 1,Shipping by containers |

| 2,Shipping by bulk ship | |

| Custom | Customization is available upon request |

Why Choose Us?

- Price Advantage: We support both retail and bulk purchases for metal distributors, offering discounts and rebate policies for B2B customers. Our pricing is transparent, ensuring a competitive advantage with equivalent-quality aluminum bars.

- Fast Delivery: With thousands of tons of stock available, standard sizes can be matched directly from our existing inventory, ensuring rapid shipment. Our advanced equipment and professional team help shorten delivery times and provide convenient logistics, ensuring on-time delivery.

- High-Quality Products: We use high-quality aluminum bar billets and employ precise alloying and heat treatment processes to optimize product strength and ductility. Our uniform cooling and annealing processes ensure high tensile strength and superior performance.

- Excellent Grain Control: Produced via reverse extrusion, we control the cooling rate and homogenization process. Grain ring size is typically controlled to ≤0.5mm, reducing defects and improving material consistency, enhancing product uniformity.

- Comprehensive Quality Testing: We strictly implement multiple inspection processes, including tensile strength, elongation performance, ultrasonic testing, metallographic inspection, etc., ensuring that the aluminum bars meet AMS, EN, NADCAP, and other certification standards.

- Customer Service: We provide comprehensive after-sales service to address any customer concerns. Our experienced technical team offers professional consulting and guidance, establishing a robust customer service system to ensure a premium service experience.