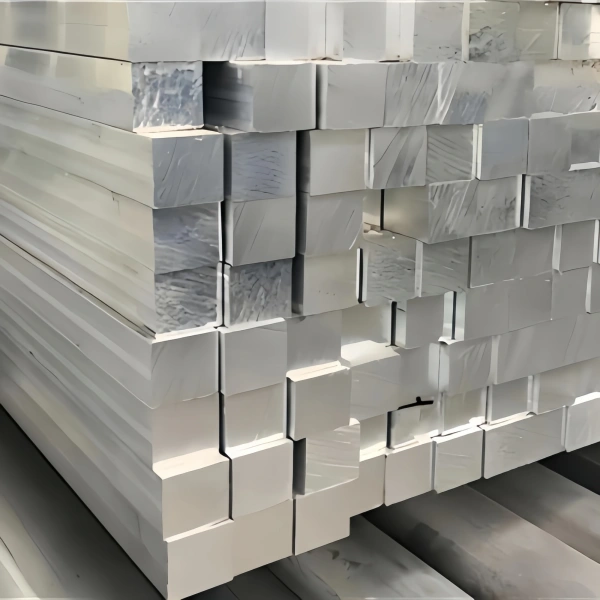

6063 Aluminum Bar

6063 aluminum bar is a premium aluminum material designed for architectural, decorative, and structural applications where appearance, corrosion resistance, and machinability are as important as strength.6063 is primarily an alloy of magnesium and silicon, an alloy that combines excellent formability, corrosion resistance, and surface finish. Therefore, 6063 aluminum rods are particularly suitable for applications with high aesthetic requirements, such as building framing, decorative moldings, and structural components requiring a high degree of surface finish.

Advantage |

Description |

|

Excellent Surface Finish |

6063 aluminum bar produces an exceptionally smooth, uniform surface with excellent reflectivity, making it ideal for architectural and decorative applications where appearance is critical. |

|

Superior Anodizing |

The alloy responds exceptionally well to the anodizing process, creating a protective oxide layer that significantly improves corrosion resistance while allowing for a wide range of colors and finishes. |

|

Outstanding Corrosion Resistance |

The alloy’s natural corrosion resistance is further enhanced through anodizing or other surface treatments, ensuring reliable performance in harsh environments including coastal and marine applications. |

|

Versatile Forming |

6063 alloy easily extrudes into complex shapes and profiles, facilitating creation of custom architectural and decorative elements with precise dimensions and intricate details. |

|

Good Workability |

6063 aluminum allows easy machining, drilling, and forming with standard techniques, particularly in softer tempers, providing flexibility in manufacturing processes. |

|

Excellent Thermal Conductivity |

The 6063 aluminum’s thermal conductivity properties make it suitable for applications where heat dissipation is beneficial, particularly in lighting and electronic applications. |

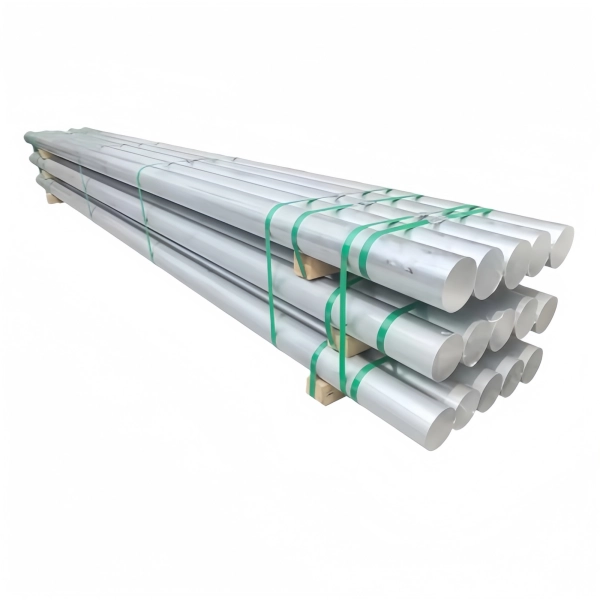

Our 6063 aluminum bar rod conform to international standards such as ASTM B221, ASTM B211, AMS 4156, EN 755 and AMS-QQ-A-200/8. We can also provide Material Testing Certificates (MTC) and third-party inspection reports upon request to ensure quality assurance and traceability for your critical applications. We offer a variety of thicknesses and widths to meet diverse application needs, and provide standard and custom sizes to meet specific design requirements.

HSTF Aluminum is a high-quality 6063 aluminum bar rod supplier and manufacturer in China.We have large stock, factory direct price, quality assurance, fast delivery.

Specification

| Alloy | 6063 aluminum bar |

| Temper | T4, T5, T6, T52, O |

| Out Diameter | 6mm-150mm |

| Length | 4000mm, 6000mm |

| Standard | BS H9 Alloy 6063 DTD 372B 6063 Bars and Sections AMS 4156 6063-T6 Extrusions QQ-A-200/9 6063 |

6063 Aluminum Bar Chemical Composition

| Element | Composition % |

| Si | 0.20-0.60 |

| Fe | 0.35 |

| Cu | 0.10 |

| Mn | 0.10 |

| Mg | 0.45-0.90 |

| Ti | 0.10 |

| Al | Remainder |

HSTF 6063 Aluminum Flat Bar Temper

6063 T4 Aluminum Bar

6063 T4 aluminum bar rod is an extruded product that has been solution heat-treated and then naturally aged to achieve its mechanical properties.

Properties: This temper offers moderate strength, excellent corrosion resistance, and good workability. It is often used in applications where good mechanical properties and a smooth surface finish are required, such as architectural applications.

6063 T5 Aluminum Bar

The 6063 T5 aluminum bar rod is also an extruded product, but it is cooled from the extrusion process and then artificially aged.

Properties: This temper provides higher strength than T4, making it suitable for structural applications. It is known for its good surface finish and corrosion resistance, often used in architectural frames, window frames, and other applications.

6063 T6 Aluminum Bar

The 6063 T6 aluminum bar rod undergoes a more rigorous heat treatment process, involving solution heat treatment followed by artificial aging.

Properties: T6 offers the highest strength among the 6063 tempers while maintaining good corrosion resistance and workability. It is commonly used in structural applications and components requiring enhanced strength.

6063 T52 Aluminum Bar

The 6063 T52 aluminum bar rod is a variation of the T5 temper but with specific modifications in the manufacturing process that enhance its properties.

Properties: T52 offers improved strength compared to T5 and is often used in applications where higher strength and good weldability are required. It still retains good corrosion resistance and is suitable for structural applications.

|

Mechanical Property of 6063 Aluminum Bar |

|||||

| Alloy | Temper | Tension strength(MPa) | Yield strength(MPa) | Elongation(%) | Hardness(HB) |

| 6063 | O | ≤90 | ≤50 | ≥15 | ≤35 |

| T4 | ≥130 | ≥60 | ≥12 | 50-75 | |

| T5 | ≥160 | ≥110 | ≥8 | 60-85 | |

| T6 | ≥205 | ≥170 | ≥8 | 75-90 | |

Tell us your specific machining requirements or intended use, and our engineers will provide professional machining solutions to ensure the finished product meets your project requirements.

HSTF 6063 Aluminum Bar Product

6063 Extruded Aluminum Bar

The 6063 aluminum alloy forms this extruded bar with specific design for aerospace applications.

It typically meets stringent aerospace standards, offering a lightweight, high-strength solution with excellent corrosion resistance. This type serves in various components of aircraft structures.

6063 Forged Aluminum Bar

The 6063 aluminum alloy forms 6063 forged aluminum bar through a forging process that enhances its mechanical properties.

Properties: Forged bars demonstrate superior strength and toughness compared to extruded bars, making them suitable for high-stress aerospace components and applications.

6063 Aluminum Round Bar

6063 aluminum round bar is a versatile, medium-strength aluminum alloy known for its excellent corrosion resistance, smooth surface finish, and ease of machining. Ideal for architectural, structural, and decorative applications, it offers good weldability and formability. Commonly used in tubing, frames, and extrusions, 6063 provides a balance of strength, durability, and aesthetics.

6063 Aluminum Square Bar

6063 aluminum square bar is a lightweight, corrosion-resistant aluminum alloy with a smooth finish and strong machinability. It is known for its excellent weldability and formability, and it finds wide use in architectural, structural, and decorative applications. The square shape provides stability and precision, making it ideal for framing, supports, and custom fabrications.

6063 Aluminum Flat Bar

6063 aluminum flat bar is a versatile, corrosion-resistant aluminum alloy with excellent machinability and weldability. Known for its smooth surface and structural integrity, it’s ideal for framing, brackets, and architectural applications. The flat shape ensures easy handling and precise fitting in construction, machinery, and decorative projects.

HSTF 6063 Aluminum Bar Stock

6063 Aluminum Bar Chemical Composition |

|

| Description | Diameter (inches) |

| 3⁄16″ 6063 T52 Aluminum Round Bar | 0.1875 |

| 5⁄16″ 6063 T52 Aluminum Round Bar | 0.3125 |

| 3⁄8″ 6063 T52 Aluminum Round Bar | 0.375 |

| 7⁄16″ 6063 T52 Aluminum Round Bar | 0.4375 |

| 9⁄16″ 6063 T52 Aluminum Round Bar | 0.5625 |

| 5⁄8″ 6063 T52 Aluminum Round Bar | 0.625 |

| 7⁄8″ 6063 T52 Aluminum Round Bar | 0.875 |

| 1″ 6063 T52 Aluminum Round Bar | 1 |

| 1 1⁄8″ 6063 T52 Aluminum Round Bar | 1.125 |

| 1 1⁄4″ 6063 T52 Aluminum Round Bar | 1.25 |

| 1 1⁄2″ 6063 T52 Aluminum Round Bar | 1.5 |

| 1 3⁄4″ 6063 T52 Aluminum Round Bar | 1.75 |

| 2″ 6063 T52 Aluminum Round Bar | 2 |

| 2 1⁄2″ 6063 T52 Aluminum Round Bar | 2.5 |

| 3″ 6063 T52 Aluminum Round Bar | 3 |

| 4″ 6063 T52 Aluminum Round Bar | 4 |

| 5″ 6063 T52 Aluminum Round Bar | 5 |

6063-T52 Extruded Aluminum Flat Bar |

||

| Description | Thickness (in) | Width (in) |

| 0.1875″ x 1″ 6063-T52 Aluminium Flat Bar | 0.1875 | 1 |

| 0.1875″ x 1.25″ 6063-T52 Aluminium Flat Bar | 0.1875 | 1.25 |

| 0.1875″ x 1.5″ 6063-T52 Aluminium Flat Bar | 0.1875 | 1.5 |

| 0.1875″ x 2″ 6063-T52 Aluminium Flat Bar | 0.1875 | 2 |

| 0.1875″ x 2.5″ 6063-T52 Aluminium Flat Bar | 0.1875 | 2.5 |

| 0.25″ x 1″ 6063-T52 Aluminium Flat Bar | 0.25 | 1 |

| 0.25″ x 1.25″ 6063-T52 Aluminium Flat Bar | 0.25 | 1.25 |

| 0.25″ x 1.5″ 6063-T52 Aluminium Flat Bar | 0.25 | 1.5 |

| 0.25″ x 1.75″ 6063-T52 Aluminium Flat Bar | 0.25 | 1.75 |

| 0.25″ x 2″ 6063-T52 Aluminium Flat Bar | 0.25 | 2 |

| 0.25″ x 2.5″ 6063-T52 Aluminium Flat Bar | 0.25 | 2.5 |

| 0.25″ x 3″ 6063-T52 Aluminium Flat Bar | 0.25 | 3 |

| 0.375″ x 0.625″ 6063-T52 Aluminum Flat Bar | 0.375 | 0.625 |

| 0.375″ x 0.75″ 6063-T52 Aluminum Flat Bar | 0.375 | 0.75 |

| 0.375″ x 1″ 6063-T52 Aluminum Flat Bar | 0.375 | 1 |

| 0.375″ x 1.25″ 6063-T52 Aluminum Flat Bar | 0.375 | 1.25 |

| 0.375″ x 1.5″ 6063-T52 Aluminum Flat Bar | 0.375 | 1.5 |

| 0.375″ x 2″ 6063-T52 Aluminum Flat Bar | 0.375 | 2 |

| 0.375″ x 3″ 6063-T52 Aluminum Flat Bar | 0.375 | 3 |

| 0.5″ x 1.5″ 6063-T52 Aluminum Flat Bar | 0.5 | 1.5 |

| 0.5″ x 2″ 6063-T52 Aluminum Flat Bar | 0.5 | 2 |

| 0.5″ x 2.5″ 6063-T52 Aluminum Flat Bar | 0.5 | 2.5 |

| 0.5″ x 3″ 6063-T52 Aluminum Flat Bar | 0.5 | 3 |

| 0.5″ x 6″ 6063-T52 Aluminum Flat Bar | 0.5 | 6 |

Our inventory is updated frequently. If you cannot find the specification you need, please contact us.

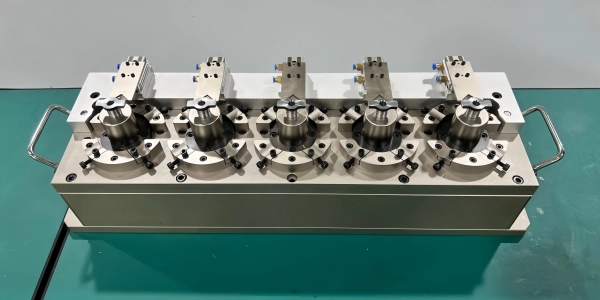

Contact Us NowHSTF Processing Services

We also offer comprehensive, customized machining services to meet your specific needs. With advanced equipment and expertise, we can machine aluminum round bars into custom components that perfectly fit your project, helping you optimize your production processes and reduce overall costs.

Professional Processing

Tell us your specific machining requirements or intended use, and our engineers will provide professional machining solutions to ensure the finished product meets your project requirements.

| Processing Services | Description |

| Surface Treatment | Polishing for a bright shine.

Anodizing for enhanced corrosion resistance and a variety of colors. Sandblasting for a uniform matte or textured surface. |

| Custom Length Cutting | Precise cutting to your specified length, ensuring accurate dimensions and reducing material waste. |

| Edge Smoothing Treatment | Deburring and chamfering for smooth, flat edges, enhancing safety and aesthetics. |

| Drilling | High-precision drilling according to drawings, ensuring perfect compatibility with your components. |

| Bending | Accurate bending and forming of aluminum flat bars according to design requirements. |

| Other | Milling, welding, and surface brushing. |

Application

Aerospace

For lightweight, non-critical structures and internal applications.

- Interior cabin frames: Formed into seat tracks, overhead bins, and partition supports that are light yet durable for passenger comfort and safety.

- Ventilation duct system: extruded into smooth, corrosion-resistant channels to achieve efficient airflow within the aircraft cabin.

- Non‑load‑bearing fairings: Shaped into aerodynamic covers and access panels where weight reduction and weather resistance are priorities.

Busbar Manufacturing

6063 has excellent electrical conductivity, corrosion resistance and outstanding extrudability, making it highly suitable for manufacturing lightweight and durable busbars in power distribution systems.

- Power distribution busbars: Extruded into flat or rectangular bars for switchgear and panel boards, offering efficient current transfer with reduced weight.

- Custom profile busbars: Machined or extruded into special shapes for compact, space‑saving connections in control panels and renewable energy systems.

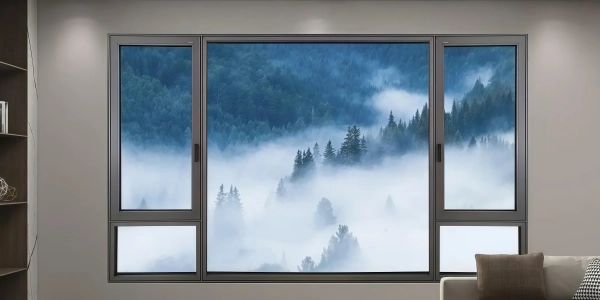

Architecture & Building Facades

Lightweight, corrosion‑resistant bar ideal for modern, aesthetic and durable exterior structures.

- Curtain wall mullions: sleek, anodizable bars create weather‑stable building envelopes.

- Window and door frames: strong, smooth bars ensure tight seals and long service life.

- Handrail and balustrade systems: attractive, corrosion‑proof bars enhance safety and design.

Heat Sinks & Electronics Enclosures

Good thermal conductivity and corrosion resistance benefit electronic cooling and housing.

- LED lighting heat sinks: efficient bars dissipate heat, extending fixture lifespan.

- Power supply casings: anodized bars protect electronics while aiding thermal management.

- Server rack frames: lightweight bars support equipment with minimal added heat load.

Transportation Components

High formability and moderate strength suit lightweight, efficient transport parts.

- Truck and trailer profiles: extruded bars reduce weight while maintaining load capacity.

- Bus interior handrails and seat frames: durable, easy‑to‑clean bars improve passenger comfort.

- Railcar interior panels and brackets: corrosion‑resistant bars lower maintenance costs.

Industrial Profiles

Easy extrusion and machining enable cost‑effective protective and structural parts.

- Machine safety guards: smooth, anodized bars provide visibility and corrosion resistance.

- Conveyor track supports: lightweight bars reduce motor load and ease maintenance.

- Custom jigs and framing: formable bars meet precise industrial layout needs efficiently.

Why Choose Us?

Quality Assurance – All products comply with ASTM, AMS, EN, ISO, ensuring high purity, uniformstructure, and stable performance.

Professional Supplier – Professional 6063 aluminum bar rod supplier in China. We have an advanced factory to ensure quality and efficiency.

Competitive Price – The mature supply chain system ensure that our products are highly competitive in cost and price.

Superior Quality – Quality supervision on whole process of production from raw materials, manufacturing, packaging, warehousing till container loading.

On-Time Delivery – The mature logistics management system and company self owned freight forwarder ensure that our OTD rate reaches 100%.

6000 Series Alloy Comparison

1. Mechanical Properties Comparison (T6 Temper)

|

Alloy Grade |

Tensile Strength (MPa) | Yield Strength (MPa) |

Elongation (%) |

Hardness (HB) |

|

6082-T6 |

≥310 | ≥260 |

≥8 |

≥80 |

|

6061-T6 |

≥310 | ≥276 | ≥12 | ≥95 |

| 6063-T6 | 205–230 | ≥170 | ≥12 |

– |

- 6082 and 6061 have similar tensile strength, but 6082 has slightly higher yield strength.

- 6063 offers the lowest strength but the best ductility.

2. Corrosion Resistance Comparison

- 6082 Aluminum Alloy: Exhibits excellent corrosion resistance, particularly in marine environments. Due to the absence of copper, its corrosion resistance is superior to 6061, performing exceptionally well in seawater and industrial atmospheric environments.

- 6061 Aluminum Alloy: Offers good corrosion resistance, but due to the presence of a small amount of copper, its performance in certain acidic and alkaline environments is not as good as 6082. Containing chromium, 6061 exhibits good resistance to stress corrosion cracking.

- 6063 Aluminum Alloy: Demonstrates excellent corrosion resistance and exhibits no tendency for stress corrosion cracking. Among heat-treatable aluminum alloys, it is the only alloy without any observed stress corrosion cracking.

3. Welding Performance Comparison

- 6082 Aluminum Alloy: Excellent weldability, suitable for various welding methods such as MIG welding and TIG welding. The weld joint strength can reach over 85% of the base metal. ER5356 or ER5183 welding wire is recommended.

- 6061 Aluminum Alloy: Excellent weldability, known as the “King of Aluminum,” with high welding speed and good weldability.

- 6063 Aluminum Alloy: Excellent weldability, good cold workability, and moderate strength.

4. Processing Performance Comparison

|

Alloy Grade |

Cold Formability | Machinability | Anodizing Quality | Extrudability |

|

6082 |

Good | Good | Good | Good |

| 6061 | Excellent | Excellent | Excellent |

Excellent |

|

6063 |

Excellent | Excellent | Excellent |

Excellent |

- 6061 has the best machinability;

- 6063 has excellent extrusion properties and is a typical extrusion alloy;

- 6082 has good machinability, but slightly inferior to 6061.

5. Selection Recommendations

- Balanced Overall Performance: Choose 6082 or 6061. 6082 has a slightly higher yield strength, while 6061 offers better machinability.

- Building Doors and Windows: Choose 6063 for optimal extrusion performance.

- Shipbuilding: Choose 6082 for excellent seawater corrosion resistance.