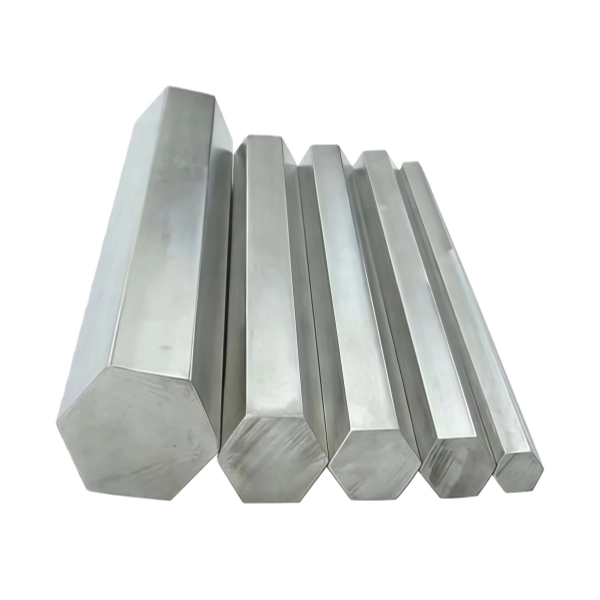

6061 T6 Aluminum Hex Bar

6061 aluminum alloy hex bar is a medium-strength, heat-treatable, forged aluminum alloy. Combining excellent properties such as strength, corrosion resistance, machinability, and weldability, 6061 is one of the most widely used aluminum alloys across various industries. Hexagonal structures offer practical advantages in applications requiring a firm grip, torque transmission, or rotational alignment, such as fasteners, shafts, valve stems, and custom-machined parts.

- 6061 Aluminum Hex Rod is an alloy made of magnesium and silicon. It has excellent corrosion resistance.

- Compared with other heat-treated aluminum, 6061 aluminum has lower strength but the strongest corrosion resistance.

- There are many different methods to form this grade of aluminum, such as machining, welding, hot working, and cold working.

- Suitable for anodizing, other coatings can also be applied, its conductivity is 40% of copper.

Our 6061 aluminum alloy hex bars conform to multiple international standards, including ASTM B221, AMS 4117, QQ-A-200/8. We can also provide Material Testing Certificates (MTC) and third-party inspection reports upon request to ensure quality assurance for your critical applications. We consistently adhere to stringent quality control standards to ensure the dimensional accuracy, mechanical properties, and surface quality of our 6061 aluminum alloy hex bars.

HSTF Aluminum is a high-quality 6061 aluminum bar supplier and manufacturer in China. We have large stock, factory direct price, quality assurance, fast delivery.

Specification

| Product Name | 6061 Aluminum Hex Bar |

| Temper | T6, T6511 |

| Standard Lengths | Up to 6 meters (approx. 20 feet), with options for fixed, cut-to-length, or custom lengths. |

| Cutting Tolerance | Standard cut tolerance approx. ±6mm (approx. ±1/4 inch); precision custom cuts available up to ±1.5mm (approx. ±1/16 inch). |

|

Standards |

ASTM B221, AMS 4117, QQ-A-200/8 |

| Package | 1. Inner protection: We wrap each aluminum rod in PE film, with optional paper, cardboard, or foam layers to resist moisture and scratches.

2. Bundle securing: The packaging process bundles and reinforces aluminum rods with steel or PET straps, with protective padding to prevent loosening and abrasion. 3. Outer packaging: We pack bulk orders in sturdy wooden crates or pallets, with optional export-grade fumigation. And moisture-proof lining for compression and shock resistance. |

6061 Aluminum Hex Bar Mechanical Properties

| Density | 2.7 g/cm3 |

| Tensile Strength | 310 MPa |

| Yield Tensile Strength | 276 MPa |

| Shear Strength | 207 MPa |

| Elongation | 17% |

| Modulus of Elasticity | 68.9 GPa |

HSTF 6061 Aluminum Hex Bar Stock

| Product | Width(inch) |

| Aluminum Hexagonal Bar 6061-T6-Extruded | 0.472″ |

| Aluminum Hexagonal Bar 6061-T6-Extruded | 0.551″ |

| Aluminum Hexagonal Bar 6061-T6-Extruded | 0.63″ |

| Aluminum Hexagonal Bar 6061-T6-Extruded | 0.669″ |

| Aluminum Hexagonal Bar 6061-T6-Extruded | 0.748″ |

| Aluminum Hexagonal Bar 6061-T6-Extruded | 0.787″ |

| Aluminum Hexagonal Bar 6061-T6-Extruded | 0.866″ |

| Aluminum Hexagonal Bar 6061-T6-Extruded | 0.945″ |

| Aluminum Hexagonal Bar 6061-T6-Extruded | 0.984″ |

| Aluminum Hexagonal Bar 6061-T6-Extruded | 1.024″ |

| Aluminium Hexagonal Bar 6061-T6-Extruded | 1.063″ |

| Aluminium Hexagonal Bar 6061-T6-Extruded | 1.102″ |

| Aluminium Hexagonal Bar 6061-T6-Extruded | 1.181″ |

| Aluminium Hexagonal Bar 6061-T6-Extruded | 1.26″ |

| Aluminium Hexagonal Bar 6061-T6-Extruded | 1.339″ |

| Aluminium Hexagonal Bar 6061-T6-Extruded | 1.417″ |

| Aluminium Hexagonal Bar 6061-T6-Extruded | 1.496″ |

| Aluminium Hexagonal Bar 6061-T6-Extruded | 1.575″ |

- Inventory size, quick delivery within 7-10 days.

- Our inventory is updated frequently. If you cannot find the specification you need, please contact us.

Application

Aerospace

6061 aluminum hex bar suitable for lightweight, durable aerospace components.

- Aircraft structural brackets and fittings: hex bar allows secure bolting and alignment in airframe assemblies.

- Wing rib and spar attachment points: easily machined into precise shapes for reliable joining.

- Fuel system valve stems and mounts: corrosion‑resistant hex bar ensures leak‑free operation in harsh conditions.

Marine Industry

Excellent resistance to seawater corrosion enables 6061 hex bar to serve reliably in boat and ship hardware.

- Deck cleats and stanchion bases: hex shape provides firm grip for wrench tightening and secure mounting.

- Hatch hinges and latch rods: corrosion‑proof material ensures long life and low maintenance.

- Rail and ladder fittings: strong yet lightweight bars simplify installation and withstand marine loads.

Machinery Parts

Good machinability and mechanical strength make 6061 hex bar ideal for producing robust industrial machine components.

- Shaft collars and gear blanks: hex bar can be turned or milled into accurate rotating parts.

- Drive couplings and linkage pins: hex form resists rotation during torque transmission.

- Pump housing studs and motor mounts: easy threading and welding for stable, vibration‑resistant assemblies.

Fixtures & Tooling

Versatile shaping and reliable performance let 6061 hex bar serve in custom jigs, fixtures, and manufacturing aids.

- Drill jig locator pins and stops: hex profile prevents slippage during setup and machining.

- Welding fixture clamps and supports: strong bars hold workpieces firmly with consistent alignment.

- Assembly line indexing guides: corrosion‑resistant hex bars ensure repeatable positioning in production.

Why Choose Us?

Quality Assurance – All products comply with ASTM, AMS, ISO, RoHS and other international standards, ensuring high purity, uniformstructure, and stable performance.

Professional Supplier – Professional 6061 T6 aluminum hex bar supplier in China. We have an advanced factory to ensure quality and efficiency.

Competitive Price – The mature supply chain system, advanced equipment and technology ensure that our products are highly competitive in cost and price.

Superior Quality – Quality supervision on whole process of production from raw materials, manufacturing, packaging, warehousing till container loading.

On-Time Delivery – The mature logistics management system and company self owned freight forwarder ensure that our OTD rate reaches 100%.