6061 Aluminum Round Bar

6061 Aluminum Round Bar is a premium heat-treatable aluminum-magnesium-silicon alloy from the 6000 series, renowned for its exceptional combination of high strength, excellent corrosion resistance, and superior machinability. This versatile alloy contains 0.8–1.2% magnesium, 0.4–0.8% silicon, and 0.15–0.40% copper, creating an optimal balance of mechanical properties, workability, and corrosion resistance. Widely used in aerospace, marine, transportation, and general engineering industries, 6061 aluminum round bars are ideal for aircraft components, yacht frames, truck structures, bicycle parts, and CNC-machined elements.

6061 Aluminum Round Bar Advantages

| Heat Treatable | 6061 aluminium alloy is a heat treatable alloy, allowing 6061 aluminum round bars to be strengthened and hardened through heat treatment. |

| Good Corrosion Resistance | with higher levels of magnesium and silicon elements, 6061 aluminum round bars exhibit excellent corrosion resistance. |

| Easy to Machine | 6061 aluminum round bars have good machinability, making them easy to cut, drill, turn, and mill for mechanical operations such as manufacturing complex parts and precision machining. |

| Good Weldability | 6061 aluminum round bars maintain good weldability even in the heat-treated state, suitable for various welding processes such as TIG welding and MIG welding. Welded joints have high strength, meeting the requirements of most engineering applications. |

| Good Electrical Conductivity | 6061 aluminium alloy has excellent thermal conductivity, making it perform well in applications requiring efficient heat dissipation. |

Our 6061 aluminum alloy round bar meet international standards, including ASTM B221, ASTM B211, AMS-QQ-A-200/8, AMS 4117, AMS 4128. Our quality management system ensures compliance with these standards and provides reliable, certified materials for your critical applications.

HSTF Aluminum is a high-quality 6061 alloy aluminum bar supplier and manufacturer in China. We have large stock, factory direct price, quality assurance, fast delivery.

Specification

| Alloy | 6061 |

| Temper | T4, T6, T651, T6511 |

| Equivalent Name | A96061; AW-AlMg1SiCu; EN AW-6061; AlMgSiCu; AlMg1SiCu; HE20; AA6061; 3.3211 |

| Manufacturing Process | Extrusion, Cold Drawing, Forging |

| Diameter Range | Common diameters 1/8″ – 16″, larger diameters by custom order |

| Length Range | 12″ – 144″ or custom |

| Color | Black, Silver-White, or custom |

| Surface Treatment | Anodizing, Powder Coating |

| Packaging | Internal protective film, external wooden boxes, or custom |

| Deep Processing | Cutting, Polishing, Machining |

| Standards | ASTM B221, ASTM B211, AMS-QQ-A-200/8, AMS 4117, AMS 4128 |

6061 Aluminum Round Bar Performance Parameter

| Density (pounds per cubic inch) | 0.098 |

| Specific Gravity | 2.7 |

| Melting Point (Fahrenheit) | 1090 |

| Ultimate Tensile Strength psi | 45, 000 |

| Yield Strength psi | 40, 000 |

| Brinell Hardness | 95 |

| Rockwell Hardness | B60 |

HSTF 6061 Aluminum Round Bar Producr

6061 Aluminum Extruded Round Bar

Produced through direct extrusion, these bars are ideal for structural components where dimensional tolerance is less critical.

Applications: Load-bearing parts, frames, marine hardware.

Available in mill finish with standard tempers T6 and T6511

6061 Cold Finished Aluminum Round Bar

Enhanced dimensional accuracy and surface finish make cold finished bars suitable for CNC turning and high-speed automatic lathes.

Applications: Shafts, bushings, pins, connectors.

Offered in T6, T651, and T6511, with optional polishing

6061 Aluminum Polished Round Bar

Surface-polished bars provide enhanced visual quality and are suitable for applications with aesthetic or post-anodizing requirements.

Applications: Decorative parts, display hardware, visible components.

Available upon request with optional anodizing support

6061 Aluminum Cut-to-Length Round Bar

We offer custom length cutting services to meet your production needs, minimizing material waste and delivery time.

Applications: Prototyping, short-run machining, batch manufacturing.

Free cutting available for selected stock sizesHSTF 6061 Aluminium Alloy Round Bar Stock

| Product | Diameter(inch) | Manufacturing method |

| 1/8″ 6061-T6 Aluminum Round Bar | 1/8″ | Cold Finish |

| 1/4″ 6061-T6 Aluminum Round Bar | 1/4″ | Cold Finish |

| 3/8″ 6061-T6 Aluminum Round Bar | 3/8″ | Cold Finish |

| 1″ 6061-T6 Aluminum Round Bar | 1″ | Cold Finish |

| 1-1/4″ 6061-T6 Aluminum Round Bar | 1-1/4″ | Cold Finish |

| 1-3/4″ 6061-T6 Aluminum Round Bar | 1-3/4″ | Cold Finish |

| 3″ 6061-T6 Aluminum Round Bar | 3″ | Cold Finish |

| 5″ 6061-T6 Aluminium Round Bar | 5″ | Cold Finish |

| 6″ 6061-T6 Aluminium Round Bar | 6″ | Cold Finish |

| 1/8″ 6061-T6 Aluminium Round Bar | 1/8″ | Extruded |

| 1/4″ 6061-T6 Aluminium Round Bar | 1/4″ | Extruded |

| 3/8″ 6061-T6 Aluminium Round Bar | 3/8″ | Extruded |

| 3/4″ 6061-T6 Aluminium Round Bar | 3/4″ | Extruded |

| 1″ 6061-T6 Aluminium Round Bar | 1″ | Extruded |

| 1-1/4″ 6061-T6 Aluminium Round Bar | 1-1/4″ | Extruded |

| 1-1/2″ 6061-T6 Aluminium Round Bar | 1-1/2″ | Extruded |

| 1-3/4″ 6061-T6 Aluminium Round Bar | 1-3/4″ | Extruded |

| 2″ 6061-T6 Aluminium Round Bar | 2″ | Extruded |

| 6″ 6061-T6 Aluminum Round Bar | 6″ | Extruded |

| 1/8″ 6061-T651 Aluminum Round Bar | 1/8″ | Cold Finish |

| 1/4″ 6061-T651 Aluminum Round Bar | 1/4″ | Cold Finish |

| 3/4″ 6061-T651 Aluminium Round Bar | 3/4″ | Cold Finish |

| 1″ 6061-T651 Aluminium Round Bar | 1″ | Cold Finish |

| 1-1/4″ 6061-T651 Aluminium Round Bar | 1-1/4″ | Cold Finish |

| 1-1/2″ 6061-T651 Aluminium Round Bar | 1-1/2″ | Cold Finish |

| 1-3/4″ 6061-T651 Aluminium Round Bar | 1-3/4″ | Cold Finish |

| 2″ 6061-T651 Aluminium Round Bar | 2″ | Cold Finish |

| 4″ 6061-T651 Aluminium Round Bar | 4″ | Cold Finish |

| 1/8″ 6061-T6511 Aluminum Round Bar | 1/8″ | Extruded |

| 1/4″ 6061-T6511 Aluminium Round Bar | 1/4″ | Extruded |

| 3/8″ 6061-T6511 Aluminium Round Bar | 3/8″ | Extruded |

| 3/4″ 6061-T6511 Aluminium Round Bar | 3/4″ | Extruded |

| 1-3/4″ 6061-T6511 Aluminium Round Bar | 1-3/4″ | Extruded |

| 2″ 6061-T6511 Aluminium Round Bar | 2″ | Extruded |

| 3″ 6061-T6511 Aluminium Round Bar | 3″ | Extruded |

| 4″ 6061-T6511 Aluminium Round Bar | 4″ | Extruded |

| 6″ 6061-T6511 Aluminium Round Bar | 6″ | Extruded |

We update our inventory frequently. If you cannot find the specification you need, please contact us.

Contact Us NowApplication

| Field | Details |

| Aerospace & Defense |

|

| Automotive & Transportation |

|

| Marine & Offshore |

|

| Industrial Machinery |

|

| Architectural & Consumer |

|

HSTF’s Production Capacity

At HSTF, We employ a fully integrated manufacturing system to produce 6061 aluminum rod, encompassing all stages from alloy smelting, extrusion, precision machining, and customized packaging. Our combined large-scale production capacity and stringent quality control enable us to meet both high-volume orders and specialized processing needs.

- High-precision extrusion production lines are suitable for a wide range of products (10 mm to 390 mm) with strict control over mechanical properties and grain structure.

- Advanced cold-working production lines, including drawing, straightening, and chamfering equipment, meet high precision and high surface quality requirements.

- Custom cutting and chamfering services are available, supported by CNC machining centers and automatic lathes with optimized feed dimensions.

- Polishing and anodizing pretreatment services are offered for architectural or decorative applications.

- Digital die inventory and a quick-change system shorten lead times for both standard and non-standard sized products.

- Fully compliant with standards such as ASTM, AMS, and ISO, ensuring quality.

- Chemical composition and mechanical property verification are performed on each batch of products, along with dimensional inspection and surface quality checks.

From raw materials to finished bars, every step is rigorously controlled to ensure consistency, reliability, and traceability, meeting the stringent requirements of customers in the aerospace, automotive, and precision engineering industries. Contact us to discuss your technical requirements or obtain a quick quote for your specific needs.

Packaging

- Inner protection: Each aluminum rod is wrapped in PE film, with optional paper, cardboard, or foam layers formoisture and scratch resistance.

- Bundle securing: Aluminum rods are bundled and reinforced with steel or PET straps, with protective padding toprevent loosening and abrasion.

- Outer packaging: Bulk orders are packed in sturdy wooden crates or pallets, with optional export-gradefumigation and moisture-proof lining for compression and shock resistance.

Why Choose Us?

Quality Assurance – All products comply with ASTM, ISO, RoHS and other international standards, ensuring high purity, uniformstructure, and stable performance.

Professional Supplier – Professional 6061 aluminum alloy rod bar supplier in China. We have an advanced factory to ensure quality and efficiency.

Competitive Price – The mature supply chain system, advanced equipment and technology ensure that our products are highly competitive in cost and price.

Superior Quality – Quality supervision on whole process of production from raw materials, manufacturing, packaging, warehousing till container loading.

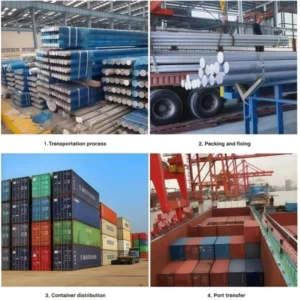

On-Time Delivery – The mature logistics management system and company self owned freight forwarder ensure that our OTD rate reaches 100%.

FQA

Yes,we promise to provide best quality products and delivery on time .Honesty is our company’s tenet.

We can provide the sample for customer with free, but the customer account will cover the courier freight.

The manufacturing process produces each piece in certified workshops. Our inspection team checks them piece by piece. This is done according to national QA/QC standards. We also could issue the warranty to customer to guarantee the quality.

We specialize in steel business for years. Our headquarters is in Liaocheng Economic Zone. This is in Shandong province. You are welcome to investigate in any way. By all means, you could place an order. Use trade assurance for your payment security.

Our team will check email and fax within 24 hours. Meanwhile, these platforms remain online 24 hours. They include Facebook, Skype, WeChat, and WhatsApp. Please send us your requirements and order information. Provide the specification details. These include steel grade, size, and quantity. Also include the destination port. We will work out the best price soon.