6061 Aluminum Bar Rod

6061 aluminum bar rod is one of the most versatile and widely used aluminum alloys, combining excellent mechanical properties with good corrosion resistance and workability. This precipitation-hardened aluminum alloy belongs to the 6000 series, which uses magnesium and silicon as its primary alloying elements. The 6061 aluminium bar offers an optimal balance of strength, corrosion resistance, and machinability, making it suitable for a broad range of industrial and commercial applications.

Our 6061 aluminum alloy bar conform to multiple international standards, including ASTM B221, AMS 4117, AMS 4115, AMS 4116, QQ-A-200/8, QQ-A-225/8, EN 3342. We can also provide Material Testing Certificates (MTC) and third-party inspection reports upon request to ensure quality assurance for your critical applications. We consistently adhere to stringent quality control standards to ensure the dimensional accuracy, mechanical properties, and surface quality of our 6061 aluminum alloy bars.

Characteristics |

Description |

| Strength and Hardness | 6061 aluminum alloy exhibits moderate to high strength and moderate hardness after appropriate heat treatment (such as T6 condition), making it suitable for withstanding certain mechanical stresses. |

| Corrosion Resistance | This alloy has good resistance to corrosion in atmospheric conditions, moisture, and marine environments, making it ideal for use in external parts of aircraft and those exposed to harsh environments. |

| Machinability | 6061 aluminum alloy has excellent machinability, allowing it to be manufactured into various shaped components through turning, milling, drilling, and other machining processes. |

| Welding Performance | The weldability of 6061 alloy is good, particularly suitable for gas-shielded welding processes (such as TIG and MIG welding), retaining high mechanical strength after welding. |

| Formability | In the annealed or T4 condition, 6061 aluminum bars can be formed through cold bending, stretching, and other methods. |

| Heat Treatment Characteristics | 6061 is an aluminum alloy that can be strengthened through heat treatment, with significantly increased strength after T6 treatment. |

HSTF Aluminum is a high-quality 6061 aluminum bar rod supplier and manufacturer in China.We have large stock, factory direct price, quality assurance, fast delivery.

Specification

| Product Name | 6061 Aluminium Bar |

| Temper | O, T4, T6, T651, T451 |

| Equivalent Name | AW-6061, 6061 (UNS A96061), EN AW-6061 (EN AW-AlMg1SiCu) |

| 6061 T4 Aluminum Bar Rod Diameter | 0.125″ – 7″ (3.175mm – 177.8mm) |

| 6061 O Aluminum Bar Rod Diameter | 0.125″ – 7″ (3.175mm – 177.8mm) |

| 6061 T6/T651 Aluminum Bar Rod Diameter | 0.125″ – 7″ (3.175mm – 177.8mm) |

| 6061 T451 Aluminum Bar Rod Diameter | 0.250″ – 12″ (6.35mm – 304.8mm) |

| Standard Lengths | Up to 6 meters (approx. 20 feet), with options for fixed, cut-to-length, or custom lengths. |

| 6061 aluminum bar cold finish specification | AMS 4116 6061-T4 Cold finished bars, rod AMS 4117 6061-T6/T651 Cold finished bars, rod QQ-A-225/8 6061-T6 / T651 Cold finished bar |

|

6061 aluminum bar extruded specifications |

QQ-A-200/8 6061-T6/T6511 Extruded bar EN 3342 6061-T4 Extruded bar |

6061 Aluminum Bar Chemical Composition

| Element | Composition % |

| Si | 0.40-0.80 |

| Fe | 0.70 |

| Cu | 0.15-0.40 |

| Mn | 0.15 |

| Mg | 0.8-1.20 |

| Ti | 0.15 |

| Al | Remainder |

HSTF 6061 Aluminum Bar Temper

6061 O Aluminum Bar

The 6061 O (annealed) aluminum bar rod is in its softest state, having undergone a complete annealing process. This results in a material that is highly ductile and malleable and that can easily form and shape. While it does not possess the high strength characteristics of other tempers, it finds use in applications where workability is critical, such as in forming and bending operations.

6061 T4 Aluminum Bar

6061 T4 aluminum bar rods are made from the 6061 aluminum alloy and are heat-treated to achieve the T4 temper, which involves solution heat treatment followed by natural aging. This temper provides a good balance of strength, workability, and corrosion resistance, making it suitable for applications that require excellent machinability and moderate strength. Common uses include structural components and aerospace applications.

6061 T6/T651 Aluminum Bar

6061 T6 / T651 aluminum bar rods are heat-treated to the T6 temper, providing a significant increase in strength compared to the T4 and O tempers. The T651 designation indicates that the material’s processing includes solution heat treating, artificial aging, and stress-relieving processes to minimize distortion. It finds wide use in structural applications, aerospace components, and other high-strength applications due to its excellent mechanical properties and corrosion resistance.

6061 T4/T451 Aluminum Bar

The 6061 T4/T451 aluminium bar rods are similar to the T4 temper but have undergone additional processing (T451) to relieve residual stresses, making them more stable and less prone to warping during machining. This combination offers a good balance of strength and workability, making it suitable for applications in aerospace and structural components that require precision machining while maintaining good mechanical properties.

| 6061 Mechanical Properties Reference Table | ||||

| Temper | 6061-O | 6061-T4 | 6061-T451 | 6061-T6/T651 |

| Yield Strength | 8 ksi (55 MPa) | 34 ksi (235 MPa) | 40 ksi (275 MPa) | 45 ksi (310 MPa) |

| Tension Strength | 8 ksi (125 MPa) | 45 ksi (310 MPa) | 68 ksi (470 MPa) | 40 ksi (275 MPa) |

| Elongation | 25% | 10% | 12% | 8% |

| Hardness | 65 HB | 95 HRB | 120 HB | 95 HRB |

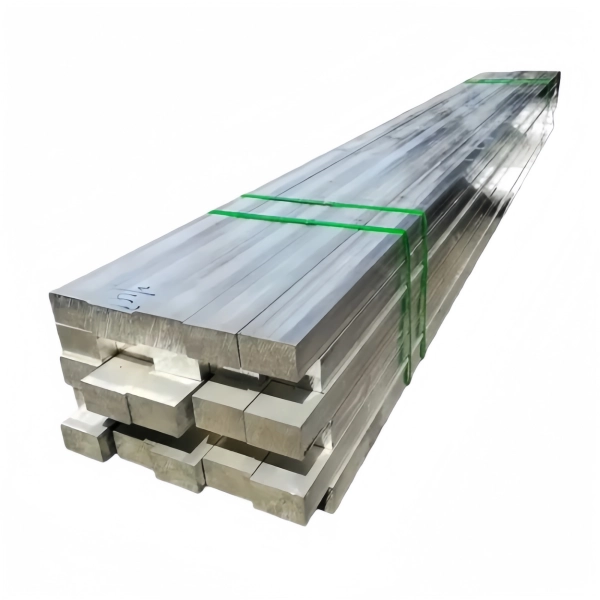

HSTF 6061 Aluminum Bar Producr

6061 Aluminum Extruded Bar

We produce 6061 aluminum extruded bar through an extrusion process, which allows for the creation of long, uniform shapes with excellent dimensional tolerances. This type of bar specifically serves aerospace applications, where lightweight and high-strength materials are essential. The extrusion process enhances the mechanical properties and surface finish, making it suitable for various structural and non-structural components in aircraft and spacecraft.

6061 Aluminum Forged Bar

We create 6061 aluminum forged bar through the forging process, which involves shaping the material using compressive forces. This process improves the grain structure, resulting in superior mechanical properties, including increased strength and toughness. Forged bars find common use in high-stress applications within the aerospace industry, such as in aircraft frames, landing gear, and other critical components.

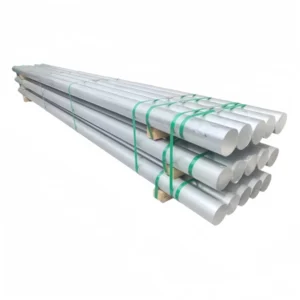

6061 Aluminum Round Bar

6061 aluminum round bar is cylindrical bars made from the 6061 alloy, specifically designed for aerospace applications. These bars are available in extruded or forged forms and feature their excellent strength-to-weight ratio and corrosion resistance. They often find use in applications requiring precision machining, such as in fasteners, fittings, and various structural components in aircraft.

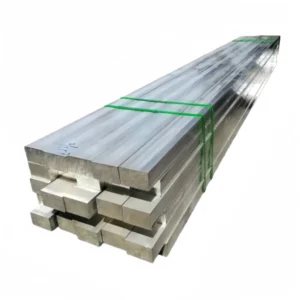

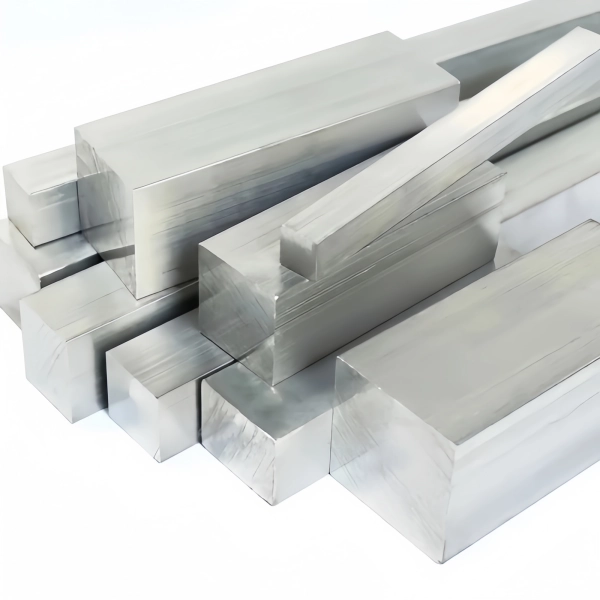

6061 Aluminum Flat Bar

6061 aluminum flat bar is flat, rectangular bars made from the 6061 alloy, designed for use in aerospace applications.6061 Aluminum Flat Bar has excellent machinability and it commonly serves applications such as support frames, structural components, and other parts that require flat materials. Their lightweight and high-strength properties make them ideal for aerospace construction.

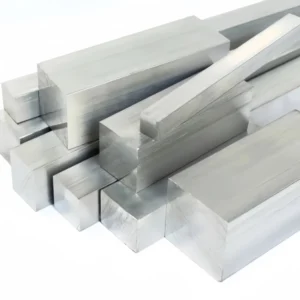

6061 Aluminum Square Bar

6061 aluminum square bar is square-shaped bars made from the 6061 alloy, tailored for aerospace applications. Similar to round bars, they offer excellent mechanical properties and corrosion resistance. Typically used in structural applications, supports, and frames, where design requirements necessitate specific cross-sectional shapes.

6061 Aluminum Hex Bar

6061 aluminum hex bar is hexagonal-shaped bars made from the 6061 aluminum alloy, designed for aerospace applications. The hexagonal shape allows for easy gripping and handling in certain applications, and like other 6061 bars, they offer excellent strength, corrosion resistance, and machinability. They often find use in applications requiring unique shapes for fittings, connectors, or other specialized components.

Application

Aerospace & Aviation

6061 aluminium bar is used in aerospace for its good strength-to-weight ratio, corrosion resistance, and weldability. It forms aircraft structural members, wing ribs, fuselage brackets, and fuel system components. Its machinability and reliability suit both commercial and general aviation applications. The bar helps reduce weight while maintaining structural integrity, contributing to fuel efficiency, safety, and long service life in demanding flight environments.

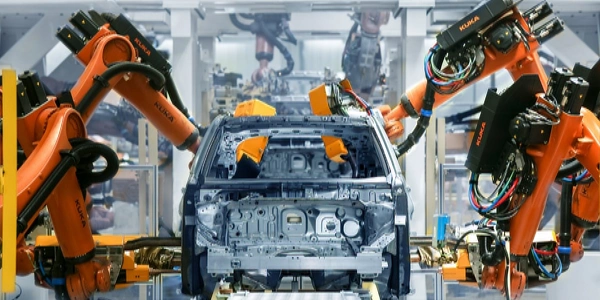

Automotive Industry

6061 aluminium bar is used for chassis frames, suspension brackets, drive shafts, and lightweight body parts. Its high strength and corrosion resistance improve vehicle durability and safety, while its light weight enhances fuel efficiency and handling. Good weldability and machinability enable complex, reliable components, making it ideal for modern automotive designs focused on performance and sustainability.

Marine & Shipbuilding

6061 aluminium bar is valued in marine applications for its corrosion resistance, strength, and weldability. It serves in hull fittings, deck hardware, railings, and structural supports for boats and ships. Its ability to withstand seawater exposure ensures durability and low maintenance. The lightweight nature aids buoyancy and performance, making it ideal for recreational craft and commercial marine structures operating in harsh aquatic environments.

Construction & Structural

6061 aluminium bar is used in construction for trusses, frames, curtain walls, and scaffolding due to its high strength, corrosion resistance, and weldability. It suits both indoor and coastal builds, enduring harsh weather with minimal upkeep. Its lightweight nature eases handling and installation, while reliable structural performance supports modern, durable architecture and infrastructure projects.

Machinery & Manufacturing

6061 aluminium bar is widely used for machine bases, shafts, gears, jigs, fixtures, and tooling frames. Its excellent machinability, weldability, and corrosion resistance ensure precise, durable components with minimal downtime. The lightweight yet strong bar simplifies assembly and reduces equipment weight, boosting efficiency and longevity in industrial manufacturing, automation, and precision engineering applications.

Sports Equipment

6061 aluminium bar is used in bicycles, golf club shafts, tent poles, fitness machines, and outdoor gear for its light weight, strength, and corrosion resistance. It enhances performance, durability, and portability, allowing athletes to enjoy reliable equipment in diverse conditions. Its good machinability enables custom designs, making it ideal for high‑quality, responsive sports and recreation products.

Why Choose Us?

Quality Assurance – All products comply with ASTM, AMS, EN and other international standards, ensuring high purity, uniformstructure, and stable performance.

Professional Supplier – Professional 6061 aluminum bar rod supplier in China. We have an advanced factory to ensure quality and efficiency.

Competitive Price – The mature supply chain system, advanced equipment and technology ensure that our products are highly competitive in cost and price.

Superior Quality – Quality supervision on whole process of production from raw materials, manufacturing, packaging, warehousing till container loading.

On-Time Delivery – The mature logistics management system and company self owned freight forwarder ensure that our OTD rate reaches 100%.

6061 Aluminum – General Purpose Alloy

6061 aluminum alloy achieves an optimal balance in key indicators such as strength, toughness, machinability, corrosion resistance, and cost, with no significant defects. It meets a wide range of application needs, from aerospace to everyday consumer goods, making it a “safe choice” and “preferred material” in industrial design.

2024 vs 6061

- Characteristics: 2024 has a reputation for its extremely high strength and fatigue resistance but has poor corrosion resistance. In contrast, 6061 offers high strength, excellent mechanical properties, good weldability, and corrosion resistance.

- Applications: 2024 finds primary use in aerospace structures and military equipment, while 6061 has broader applications in aerospace, automotive, construction, and machinery.

- Strength: 2024 has very high strength, suitable for high-stress and high-fatigue applications; 6061, though slightly lower in strength, is still suitable for a variety of high-strength applications.

6063 vs 6061

- Characteristics: 6063 offers good extrudability and corrosion resistance, and is suitable for anodizing. In contrast, 6061 provides high strength, excellent mechanical properties, and good weldability and corrosion resistance.

- Applications: 6063 finds common use for architectural profiles, door and window frames, and decorative purposes, while 6061 finds wide use in aerospace, automotive parts, structural applications, and shipbuilding.

- Strength: 6063 has lower strength, suitable for medium-strength applications, whereas 6061 has higher strength, suitable for high-strength applications.

7075 vs 6061

- Characteristics: 7075 has extremely high strength and hardness but poorer weldability and machinability. In contrast, 6061 offers a balanced performance in terms of high strength, mechanical properties, weldability, and corrosion resistance.

- Applications: 7075 finds common use in aerospace and high-strength mechanical components, while 6061 sees wide application across various industrial and construction sectors.

- Strength: 7075 has very high strength, suitable for applications requiring extreme strength; 6061 has high strength, making it suitable for a wide range of high-strength applications.

6061 Aluminum Bar Shape Selection

- 6061 Aluminum Round Bar: The most common form of bar stock, with excellent machinability, easy to machine by turning, milling, and other machining processes. Widely used in mechanical parts, shaft parts, precision instruments, mold manufacturing, electronic components, and other applications requiring circular cross-sections.

- 6061 Aluminum Square Bar: Easy to position and install, and has good structural stability. It finds its main use in applications requiring right-angle positioning. These include building structural components and frame supports. Other applications are furniture manufacturing and machinery panels.

- 6061 Aluminum Flat Bar: With a large width and small thickness, it is suitable for applications requiring a flat structure. It commonly serves for parts that require a flat shape, such as mechanical panels, brackets, guide rails, and decorative strips.

- 6061 Aluminum Hex Bar: With six opposite sides, it facilitates wrench gripping and securing, and offers excellent anti-slip properties. It primarily serves for applications requiring wrench operation, such as with bolts, nuts, tool handles, and mechanical fasteners.