5754 Aluminum Bar Rod

5754 aluminum bar is a medium-strength wrought aluminum-magnesium alloy belonging to the 5000 series. Known for its excellent corrosion resistance, good weldability, and high fatigue strength, 5754 is widely used in industries where reliability under challenging environmental conditions is critical. The main alloying elements are magnesium (approximately 2.6–3.6%) and small controlled additions of manganese, which enhance strength and resistance to stress-corrosion cracking without significantly compromising ductility.

One of the standout features of 5754 is its exceptional resistance to seawater and atmospheric corrosion, making it a top choice for marine structures, shipbuilding components, and offshore installations. The protective oxide layer formed naturally on the surface effectively prevents further oxidation, even in chloride-rich environments. In addition, 5754 shows strong resistance to many industrial chemicals and weathering effects, ensuring long service life with minimal maintenance.

5754 aluminum bar combines strength, corrosion resistance, and ease of fabrication. Therefore, it is extensively specified for pressure vessels. It is also used for vehicle bodies and bridge components. Other applications include storage tanks and marine hardware. It is also used in architectural structures.

- Our 5083 aluminum rod bar meet international standards, including ASTM B221, B211, B565, B316, ASME SB221, SB211, SB565, SB316. Our quality management system ensures compliance with these standards and provides reliable, certified materials for your critical applications.

- HSTF Aluminum is a high-quality 5754 aluminum bar rod supplier and manufacturer in China. We have large stock, factory direct price, quality assurance, fast delivery.

Specification

| Alloy | 5754 aluminum alloy |

| Temper | O, F, H14, H24, H34 H18, H28, H38, H111, H112 |

| Equivalent Names | UNS A95754; EN AW-5754; DIN AlMg3; ISO AlMg3; USA AA5754; WNR 3.3535 |

| Surface Treatment | anodizing, bright surface, black, polished … |

| Product Type | 5754 aluminum alloy cold drawn rod; 5754 aluminum alloy extruded rod |

| Length | 1-6m; can be cut to any length. |

| Standard | ASTM B221, B211, B565, B316, ASME SB221, SB211, SB565, SB316 |

5754 Aluminum Bar Chemical Composition

| Element | Composition(%) |

| Aluminum (Al) | 94.2 – 97.4 |

| Magnesium (Mg) | 2.6 – 3.6 |

| Manganese (Mn) | 0 – 0.5 |

| Silicon (Si) | 0 – 0.4 |

| Iron (Fe) | 0 – 0.4 |

| Chromium (Cr) | 0 – 0.3 |

| Zinc (Zn) | 0 – 0.2 |

| Titanium (Ti) | 0 – 0.15 |

| Copper (Cu) | 0 – 0.1 |

| Residuals | 0 – 0.15 |

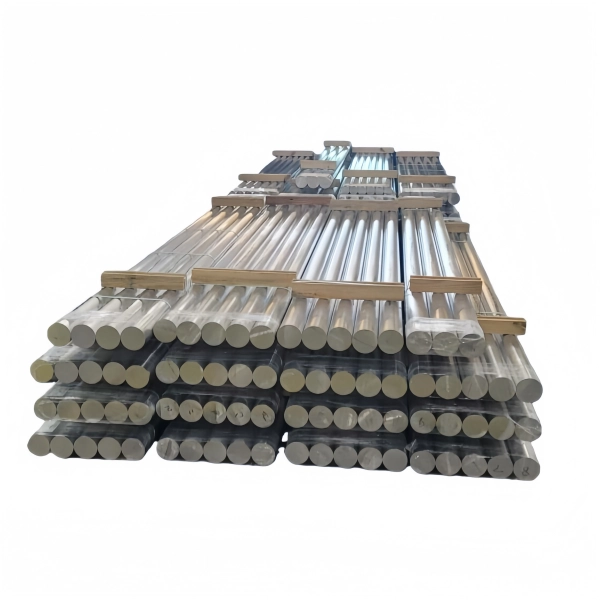

HSTF 5754 Aluminum Bar Rod Products

- HSTF offers 5754 Aluminum Round Bar, 5754 Aluminum Square Bar, 5754 Aluminum Flat Bar and 5754 Aluminum Hexagonal Bar.

5754 Cold Drawn Aluminum Bar

Temper: O/H111, H14, H24, H34 H18, H28, H38

The cold-processed 5754 aluminum bar has improved strength and surface quality. This is achieved through processing. Its yield strength and tensile strength are increased. This makes it suitable for bearing larger mechanical loads.

| 5754 Cold Drawn Rod Mechanical Properties | ||||||||

| Temper | Dimensions | Yield strength | Tensile strength | Elongation | Hardness | |||

| D | S | T | Rp0,2 | Rm | A 50 | A | ||

| mm | mm | mm | [N/mm] | [N/mm] | [%] | [%] | HBW | |

| O/H111 | ≤80 | ≤60 | ≤20 | ≥80 | 180-250 | ≥14 | ≥16 | 45 |

| H14, H24, H34 | ≤25 | ≤5 | ≤10 | ≥180 | 240-290 | ≥3 | ≥4 | 75 |

| H18, H28, H38 | ≤10 | ≤3 | ≤3 | ≥240 | ≥280 | ≥2 | ≥3 | 88 |

5754 Extruded Aluminum Bar

Temper: Temper: F, H112, O, H111

The extrusion process gives 5754 aluminum bars excellent forming ability and dimensional accuracy while maintaining excellent corrosion resistance, making them suitable for the manufacture of complex structures and precision parts.

| 5754 extruded rod mechanical properties | ||||||||

| Temper | Dimensions | Yield strength | Tensile strength | Elongation | Hardness | |||

| D | S | T | Rp0,2 | Rm | A 50 | A | ||

| mm | mm | mm | [N/mm] | [N/mm] | [%] | [%] | HBW | |

| F, H112 | ≤ 150 150 < D ≤ 250 | ≤ 150 150 < D ≤ 250 | ≤ 25 – | ≥ 80 ≥ 70 | ≥ 180 ≥ 180 | ≥ 12 – | ≥ 14 ≥ 13 | 47 |

| O, H111 | ≤150 | ≤150 | ≤25 | ≥80 | 180-250 | ≥15 | ≥17 | 45 |

Corrosion Resistance of HSTF 5754 Aluminum Bar

- Excellent Seawater Corrosion Resistance

5754 aluminum alloy belongs to the Al-Mg alloy family, containing 2.6-3.6% magnesium. In marine environments, it forms a dense oxide film, effectively resisting the erosion of seawater and salt spray. Its corrosion resistance is far superior to ordinary carbon steel, with a corrosion rate in seawater only 1/10 to 1/20 that of carbon steel.

- Good Resistance to Pitting and Crevice Corrosion

This alloy is not prone to pitting and crevice corrosion in marine environments, making it particularly suitable for welded structures and riveted joints in ships—areas prone to water accumulation.

- Control of Galvanic Corrosion in Contact with Dissimilar Metals

In marine applications, 5754 aluminum alloy often comes into contact with dissimilar metals such as stainless steel and copper alloys. Through proper insulation treatment and coating protection, the method can effectively control galvanic corrosion.

- Corrosion Resistance in Welded Areas

5754 aluminum alloy has good weldability. The corrosion resistance of the welded joint area is comparable to that of the base material, and its corrosion resistance remains largely unaffected by the heat-affected zone of welding.

- Ready to Use Without Surface Treatment

In typical marine environments, 5754 aluminum alloy can serve directly without additional anti-corrosion coatings, significantly reducing maintenance and operating costs.

These properties make 5754 aluminum alloy an ideal material choice for marine engineering applications such as ship decks, hull structures, and outfitting components.

Comparison of Corrosion Resistance with Other Marine Aluminum Alloys

| Alloy | Description | Ship Application Scenarios |

| 5052 | With the lowest magnesium content, a more uniform oxide film composition, and the weakest susceptibility to stress corrosion cracking (SCC), it exhibits a corrosion rate of <0.01 mm/year in seawater and maintains excellent corrosion resistance even after 5 years of exposure. Its Cr content is 0.15-0.35%, which allows it to form a diffusely distributed Cr-rich second phase, effectively hindering the expansion of intergranular corrosion channels, making it particularly suitable for humid atmospheric and freshwater environments. | Suitable for low-load components such as marine sheet metal parts, instrument brackets, and street light brackets, especially suitable for marine environments with extremely high corrosion resistance requirements. |

| 5754 | With a magnesium content between 5052 and 5083, it belongs to the medium-strength aluminum alloy category and possesses good corrosion resistance, weldability, and processability. In ship structures, it finds main use in parts requiring medium strength and high corrosion resistance, such as ship structures and offshore facilities, and transport tanks. | Widely used in welded structures, storage tanks, pressure vessels, ship structures, and other applications requiring moderate strength and excellent corrosion resistance. |

| 5083 | The highest magnesium content significantly improves strength, but Mg₂Al₃ precipitates easily form at grain boundaries, leading to slightly higher susceptibility to stress corrosion cracking. Optimizing the rolling process or annealing treatment is needed to reduce precipitate segregation and improve corrosion resistance. The 5083-H32 temper exhibits a fatigue strength of 140 MPa after 10⁷ cycles; surface shot peening can improve fatigue strength by 15%-20%. | Primarily used in heavy-load structural components such as ship hulls and offshore platforms, its high strength and excellent weldability make it one of the preferred materials for shipbuilding. |

All three alloys have good resistance to seawater corrosion, but 5052 performs best in terms of corrosion resistance, 5083 is superior in terms of strength, and 5754 achieves a balance in overall performance. Users can choose according to the strength, corrosion resistance and cost requirements of specific application scenarios.

HSTF also offers 5052 aluminum bar and 5083 aluminum bar. Please contact us for more information.

Application

Marine Engineering

5754 aluminum bar is ideal for marine use due to its excellent corrosion resistance and good strength. It serves in hull frames, deck supports, and structural braces in boats and ships, withstanding seawater and salt exposure. Its weldability enables durable joints in fuel tanks and superstructures. The bar’s formability allows custom shapes for fittings and accessories, ensuring reliable, low‑maintenance performance in harsh marine environments.

Automotive Panels & Parts

5754 aluminum bar is valued in automotive applications for its good formability, weldability, and corrosion resistance. It finds use for fuel tanks, body panel brackets, and chassis components where lightweight and durability matter. Its ability to allow easy shaping and joining makes it ideal for complex parts that resist road chemicals and moisture, helping reduce vehicle weight, improve fuel efficiency, and ensure long‑term reliability.

Building & Construction

5754 aluminum bar is used where weather resistance and structural stability are needed. It serves in curtain wall frames, roofing systems, and signage supports, withstanding rain, sun, and coastal corrosion. Its good formability allows custom shapes for architectural details, while weldability ensures strong joints. The lightweight yet sturdy bar simplifies installation, offering durable, low‑maintenance solutions for modern buildings and infrastructure.

Pressure Vessels & Storage Tanks

5754 aluminum bar is used for fabricating pressure vessels and storage tanks thanks to its excellent corrosion resistance, good weldability, and adequate strength. It suits tanks for fuels, chemicals, and liquids, especially in marine and industrial settings. Its formability allows complex shapes, while reliable joints ensure safe, leak‑free operation and long service life in demanding storage and pressure applications.

Package

| Packing | 1,Generaally package:Anti-water paper+strapped with min three strapping strips. |

| 2,Standard exporting package:Anti-water paper and plastic+covered by iron shrrt+strapped with min three strapping strips. | |

| 3,Excellent package:Anti-water paper and plastic film+covered by iron sheet+strapped with min three strapping strip+fixed on the iron or wooden pallets by strapping strips. | |

| Shipping | 1,Shipping by containers |

| 2,Shipping by bulk ship | |

| Custom | Customization is available upon request |

Why Choose Us?

Quality Assurance – All products comply with ASTM, ISO, ensuring high purity, uniformstructure, and stable performance.

Professional Supplier – Professional 5754 aluminum bar rod supplier in China. We have an advanced factory to ensure quality and efficiency.

Competitive Price – The mature supply chain system ensure that our products are highly competitive in cost and price.

Superior Quality – Quality supervision on whole process of production from raw materials, manufacturing, packaging, warehousing till container loading.

On-Time Delivery – The mature logistics management system and company self owned freight forwarder ensure that our OTD rate reaches 100%.