5086 Aluminum Alloy Bar

5086 aluminum alloy bar is a non-heat-treatable Al-Mg (5xxx) alloy with excellent corrosion resistance (especially in seawater and marine environments), a high strength-to-weight ratio, and excellent weldability. It is often referred to as a “sister alloy” to 5083 aluminum alloy, but with higher strength.

5086 finds wide use in marine/offshore structures, shipbuilding, chemical and process equipment, pressure vessels, transportation and automotive parts, and building framing, where durability and reliability under harsh conditions are crucial.

HSTF supplies a wide range of aluminum rods in various processes, including extruded rods, cold-finished rods, and cast billets. Specific dimensions and size ranges are as follows:

5086 Extrusion Aluminum Bar

- Temper: F, O, H111, H112

- DIA: 0.4″-16″(10-420mm)

- Spec: ASTM B221,EN 755

Cold-Finished 5086 Aluminum Bar

- Temper: O, H111, H12,H22,H32,

- DIA: 0.125″-8″(3-200mm)

- Spec: EN 754

5086 Aluminum Cast Billets Bar

- Temper: F

- DIA: 4.8″-53″(124-1350mm)

- For subsequent extrusion production

Specification

| Alloy | 5086 Alloy |

| Temper | F, O, H111, H112, H22, H32 |

| Equivalent Name | UNS A95086, EN-AW 5086, DIN AlMg4Mn, AW‑AlMg4, USA AA 5086 |

| Processing | Extrusion, cold finished, casting |

| Surface Treatment | mill finish, anodized, bright, black, polished … |

| Length | 1-6m; can be cut to any length. |

| Standard | AMS-QQ-A-200/5, EN 755, EN 754, ASTM B221 |

5086 Aluminum Chemical Composition

| Element | Composition(%) |

| Si | 0.40 |

| Fe | 0.50 |

| Cu | 0.10 |

| Mn | 0.2-0.7 |

| Mg | 3.5-4.5 |

| Cr | 0.01-0.25 |

| Zn | 0.25 |

| Ti | 0.15 |

| Others (Each) | 0.05 |

| Others (Total) | 0.15 |

| Al | Rem |

5086 Aluminum Physical Properties

| Physical Property | Value |

| Density | 2.66 g/cm³ |

| Melting Point | 585 – 640.6 °C |

| Thermal Expansion | 23.8 x10^-6 /K |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 125 W/m.K |

| Electrical Resistivity | 0.00000549 ohm-cm |

5086 Extruded Aluminum Bar Physical Properties

| Mechanical Properties |

F |

O/H111 |

H112 |

| Tensile strength Rm/Mpa |

240 |

240-320 |

240 |

| Yield strength Rp0.2/Mpa |

95 |

95 |

9 5 |

| Elongation |

10-12% |

15-18% |

10-12% |

| Hardness |

65 |

65 |

6 5 |

5086 Extruded Aluminum Bar Physical Properties

|

Mechanical Properties |

O/H111 | H12 | H22 |

H32 |

| Tensile strength Rm/Mpa |

240-320 |

270 | 270 |

270 |

| Yield strength Rp0.2/Mpa |

95 |

190 |

190 |

191 |

| Elongation |

14-16% |

4-5% | 4-5% |

4-5% |

| Hardness |

65 |

85 |

85 |

86 |

HSTF 5086 Aluminum Alloy Rod Products

5086 O Aluminum Rod Bar

The 5086 O aluminum rod is fully annealed, offering excellent ductility and formability, making it easy to process further. Though it has lower strength, it is the ideal choice in applications where good formability is required, such as hulls or complex structural components. It is particularly suitable for marine and corrosive environments.

5086 H111 Aluminum Rod Bar

The 5086 H111 aluminum rod has undergone slight work hardening, providing slightly higher strength than the O temper while maintaining good formability. It is widely used in marine, structural components, and other areas that require moderate strength and corrosion resistance, making it suitable for medium-load marine applications.

5086 H112 Aluminum Rod Bar

5086 H112 aluminum rod undergoes natural hardening after processing, offering higher strength than both O temper and H111 temper, with medium strength and good corrosion resistance. It finds common use in marine and structural applications requiring moderate strength and dimensional stability, especially in shipbuilding, storage tanks, and pressure vessels.

5086 F Aluminum Cast Billets Bar

Generally, 5086 F aluminum rod has not undergone specific work hardening or heat treatment, resulting in relatively unstable mechanical properties. However, it is ideal as an extrusion billet, providing flexibility for subsequent processing and forming operations.

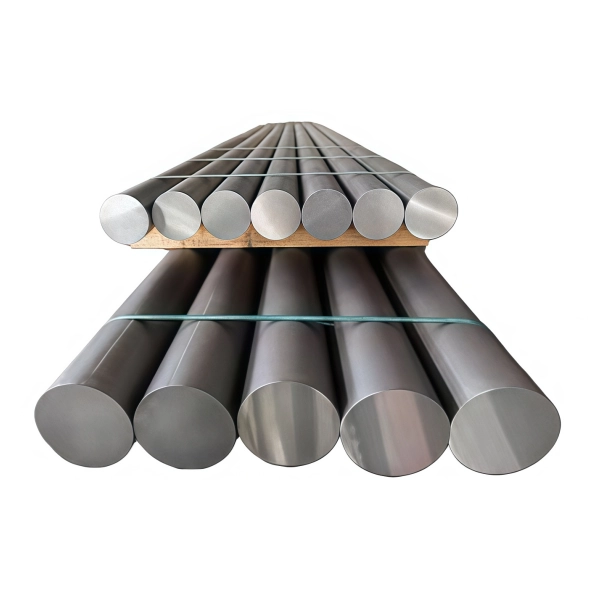

5086 Aluminum Round Bar

Diameter: 5-420mm

The round-section 5086 aluminum rod is the most commonly used shape. It can be extruded into various tubes or custom parts. It is typically used in ship shafts, drilling platform transmission systems, hydraulic systems, starter systems, and bolts and nuts connecting ship equipment.

5086 Aluminum Square Bar

Size: 10x10mm to 200x200mm

The square-section 5086 aluminum bar features equal-sized sides, providing excellent stability. It is generally used in ship superstructures, drilling platform frames, or areas requiring structural stability, such as door tracks in cabins.

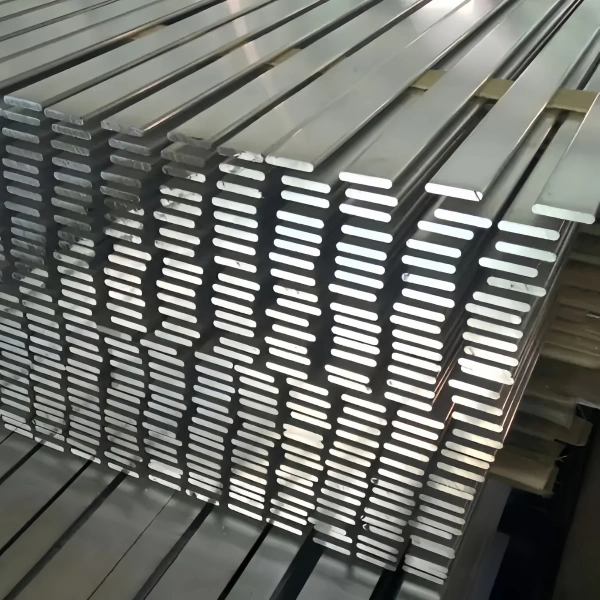

5086 Aluminum Flat Bar

Size: 10x12mm to 100x250mm

The rectangular-section 5086 aluminum rod is commonly used as a reinforcement rib to increase the stiffness of structures like hulls and pressure vessels. It can also be used as a connector, such as joining hull panels to the keel or connecting the main and secondary keels.

HSTF 5086 Aluminum Alloy Bar Stock

5086 Aluminum Round Bar |

||

| 1/2″ | 1-5/8″ | 3-1/2″ |

| 9/16″ | 1-3/4″ | 3-5/8″ |

| 5/8″ | 1-7/8″ | 3-3/4″ |

| 11/16″ | 2″ | 4″ |

| 3/4″ | 2-1/8″ | 4-1/2″ |

| 13/16″ | 2-1/4″ | 5″ |

| 7/8″ | 2-3/8″ | 6″ |

| 15/16″ | 2-1/2″ | 7″ |

| 1″ | 2-5/8″ | 8″ |

| 1-1/8″ | 2-3/4″ | 10″ |

| 1-1/4″ | 3″ | 12″ |

5086 Aluminum Square Bar |

||

| 1/4″ | 1-1/4″ | 3″ |

| 3/8″ | 1-3/8″ | 3-1/2″ |

| 1/2″ | 1-1/2″ | 4″ |

| 5/8″ | 1-3/4″ | 4-1/2″ |

| 3/4″ | 2″ | 5″ |

| 1″ | 2-1/2″ | 6″ |

5086 Aluminum Rectangular/Flat Bar |

||

| 1/8″ x 1/2″ | 5/16″ x 2″ | 3/4″ x 4″ |

| 1/8″ x 3/4″ | 5/16″ x 2-1/2″ | 3/4″ x 5″ |

| 1/8″ x 1″ | 5/16″ x 3″ | 3/4″ x 6″ |

| 1/8″ x 1-1/4″ | 5/16″ x 4″ | 3/4″ x 8″ |

| 1/8″ x 1-1/2″ | 3/8″ x 1″ | 3/4″ x 10″ |

| 1/8″ x 2″ | 3/8″ x 1-1/4″ | 3/4″ x 12″ |

| 1/8″ x 3″ | 3/8″ x 1-1/2″ | 1″ x 2″ |

| 1/8″ x 4″ | 3/8″ x 2″ | 1″ x 3″ |

| 1/8″ x 5″ | 3/8″ x 2-1/2″ | 1″ x 4″ |

| 3/16″ x 1-1/4″ | 3/8″ x 5″ | 1″ x 8″ |

| 3/16″ x 1-1/2″ | 3/8″ x 6″ | 1″ x 10″ |

| 3/16″ x 2″ | 3/8″ x 8″ | 1″ x 12″ |

| 3/16″ x 2-1/2″ | 3/8″ x 10″ | 1-1/2″ x 2″ |

| 3/16″ x 3″ | 3/8″ x 12″ | 1-1/2″ x 3″ |

| 3/16″ x 4″ | 1/2″ x 1″ | 1-1/2″ x 4″ |

| 1/4″ x 1″ | 1/2″ x 2-1/2″ | 1-1/2″ x 8″ |

| 1/4″ x 1-1/4″ | 1/2″ x 3″ | 1-1/2″ x 10″ |

| 1/4″ x 1-1/2″ | 1/2″ x 4″ | 1-1/2″ x 12″ |

| 1/4″ x 2″ | 1/2″ x 5″ | 2″ x 2″ |

| 1/4″ x 2-1/2″ | 1/2″ x 6″ | 2″ x 3″ |

| 1/4″ x 3″ | 1/2″ x 8″ | 2″ x 4″ |

| 1/4″ x 5″ | 3/4″ x 1″ | 2″ x 8″ |

| 1/4″ x 6″ | 3/4″ x 1-1/2″ | 2″ x 10″ |

| 1/4″ x 12″ | 3/4″ x 3″ | 3″ x 6″ |

The above are some stock sizes for HSTF 5086 aluminum bars. Our stock is frequently updated, and if you cannot find a product that suits your needs, you can communicate with our sales staff regarding specific products. All lengths can be cut.

Contact Us NowApplication

Shipbuilding

5086 aluminum is widely used in shipbuilding due to its excellent welding properties and strong resistance to seawater corrosion. It is often utilized for constructing hulls, superstructures, and gangways. It is the preferred material for the hulls of small aluminum boats and large yachts.

Marine Industry

The exceptional seawater corrosion resistance of 5086 aluminum alloy, combined with its outstanding weldability and high strength, makes it a top choice in the marine industry. It is commonly used in offshore drilling platforms, desalination plants, and subsea cable pipelines.

Pressure Vessels

Due to its corrosion resistance and excellent welding properties, 5086 aluminum finds wide application in the production of pressure vessels and cryogenic tanks. It sees frequent use for pipe fittings and gas pipelines in pressure vessels, enhancing the durability and safety of these containers.

Military

Aluminum 5086 plays a significant role in the military field and often serves to manufacture non-load-bearing components for armored vehicles, ships and aircraft.

Package

| Packing | 1,Generaally package:Anti-water paper+strapped with min three strapping strips. |

| 2,Standard exporting package:Anti-water paper and plastic+covered by iron shrrt+strapped with min three strapping strips. | |

| 3,Excellent package:Anti-water paper and plastic film+covered by iron sheet+strapped with min three strapping strip+fixed on the iron or wooden pallets by strapping strips. | |

| Shipping | 1,Shipping by containers |

| 2,Shipping by bulk ship | |

| Custom | Customization is available upon request |

Why Choose Us?

Quality Assurance – All products comply with ASTM, EN, ISO, ensuring high purity, uniformstructure, and stable performance.

Professional Supplier – Professional 5086 aluminum rod bar supplier in China. We have an advanced factory to ensure quality and efficiency.

Competitive Price – The mature supply chain system ensure that our products are highly competitive in cost and price.

Superior Quality – Quality supervision on whole process of production from raw materials, manufacturing, packaging, warehousing till container loading.

On-Time Delivery – The mature logistics management system and company self owned freight forwarder ensure that our OTD rate reaches 100%.

FQA

Yes,we promise to provide best quality products and delivery on time .Honesty is our company’s tenet.

We can provide the sample for customer with free, but the customer account will cover the courier freight.

The manufacturing process produces each piece in certified workshops. Our inspection team checks them piece by piece. This is done according to national QA/QC standards. We also could issue the warranty to customer to guarantee the quality.

We specialize in steel business for years. Our headquarters is in Liaocheng Economic Zone. This is in Shandong province. You are welcome to investigate in any way. By all means, you could place an order. Use trade assurance for your payment security.

Our team will check email and fax within 24 hours. Meanwhile, these platforms remain online 24 hours. They include Facebook, Skype, WeChat, and WhatsApp. Please send us your requirements and order information. Provide the specification details. These include steel grade, size, and quantity. Also include the destination port. We will work out the best price soon.