5056 Aluminum Bar Rod

5056 aluminum bar is a wrought aluminum-magnesium alloy belonging to the 5000 series, renowned for its excellent corrosion resistance—particularly in marine and aggressive industrial environments—and its good combination of strength and ductility.

The 5056 aluminum alloy offers good formability and machinability, commonly supplied in cold-finished bars for cold heading, suitable for producing bolts, screws, rivets, and other fasteners. Although it cannot be strengthened through heat treatment, its inherent high strength and corrosion resistance allow it to maintain superior performance in various demanding environments.

- Our 5056 aluminum rod bar meet international standards, including ASTM B211, ASTM B316, AMS-QQ-A-430, AMS 4182. Our quality management system ensures compliance with these standards and provides reliable, certified materials for your critical applications.

- HSTF Aluminum is a high-quality 5056 aluminum bar rod supplier and manufacturer in China. We have large stock, factory direct price, quality assurance, fast delivery.

Specification

| Alloy | 5056 aluminum alloy |

| Temper | O, F, H111, H112, H32, H34, H36, H38 |

| Product Type | Cold-finished aluminum bar, aluminum wire rod for rivets/cold heading, casting billet |

| Length | 1-6m; can be cut to any length. |

| Standard | ASTM B211, ASTM B316, AMS-QQ-A-430, AMS 4182 |

5056 Aluminum Bar Temper Type Features

|

Temper |

Features |

|

O |

Lowest strength, highest ductility, ideal for deep drawing/cold heading and subsequent hardening. |

|

F |

Mechanical properties not specified; suitable for general fabrication without controlled work‑hardening or heat treatment. |

|

H111 |

Slightly work‑hardened for better strength than O while retaining good formability and corrosion resistance, commonly used for marine and chemical equipment. |

|

H112 |

Moderate strength with good plasticity from thermomechanical processing, typically for bar/rod stock needing further machining or cold working. |

|

H32 |

Quarter‑hard with a good balance of strength and formability, suitable for cold‑finished parts needing dimensional stability. |

|

H34 |

Half‑hard offering higher strength and lower ductility than H32 for more demanding service with limited forming. |

|

H36 |

Three‑quarter‑hard providing strength close to H38 with usable ductility for parts requiring higher load capacity but some post‑forming. |

|

H38 |

Full‑hard with maximum strength and minimal ductility, typically for cold‑headed fasteners/rivets after final forming. |

5056 Aluminum Bar Chemical Composition

| Element | Composition(%) |

| Si | 0.30 |

| Fe | 0.40 |

| Cu | 0.10 |

| Mn | 0.05-0.20 |

| Mg | 4.5-5.6 |

| Cr | 0.05-0.20 |

| Zn | 0.10 |

| Others (Each) | 0.05 |

| Others (Total) | 0.15 |

| Al | Rem |

Why 5056 Aluminum Bar Suitable for Cold Heading?

- Excellent Formability: The 5056 aluminum alloy exhibits good formability, allowing it to withstand significant deformation during the cold heading process without cracking. This makes it ideal for producing various complex-shaped components, such as rivets, screws, and other fasteners.

- High Strength: The high magnesium content in 5056 aluminum alloy gives it considerable tensile strength even without heat treatment. During the cold heading process, the alloy maintains its strength, ensuring that the produced parts meet structural requirements.

- Outstanding Corrosion Resistance: 5056 aluminum alloy offers excellent resistance to saltwater and atmospheric corrosion, making it especially suitable for marine environments and other harsh conditions. In cold heading applications, many parts need to endure highly corrosive environments for extended periods, and the corrosion resistance of 5056 aluminum alloy provides a significant advantage.

- Good Machinability: 5056 aluminum alloy has good machinability, enabling precise shaping and sizing during the cold heading process, thereby improving production efficiency and part accuracy.

- Suitable for Low-Temperature Environments: 5056 aluminum alloy retains high strength and stability even at low temperatures, making it particularly suitable for cold heading applications requiring low-temperature resistance.

- Weldability: The 5056 aluminum alloy has good weldability, ensuring strong connections between parts formed during the cold heading process. This is especially important for high-precision and high-strength components.

Corrosion Resistance Comparison

Comparison of Seawater Corrosion Resistance

- 5056 aluminum alloy exhibits the best corrosion resistance in seawater and industrial atmospheric environments, outperforming 5052 and 5083 alloys. At room temperature, 5056 aluminum alloy resists corrosion from most acid, alkali, and salt solutions, making it particularly suitable for marine engineering and shipbuilding.

- 5083 aluminum alloy also possesses good seawater corrosion resistance, showing good resistance to atmospheric, freshwater, seawater, alcohol, gasoline, diesel, organic acids, and concentrated nitric acid. Its seawater corrosion resistance is superior to 5052 alloy.

- 5754 aluminum alloy is a medium-corrosion-resistant alloy, with a magnesium content between 5052 and 5083. In marine environments, it effectively resists seawater and salt spray erosion, but its corrosion resistance is slightly lower than 5056 and 5083.

- 5052 aluminum alloy has relatively weak seawater corrosion resistance. Although it has good corrosion resistance in atmospheric and freshwater environments, its performance in high-salinity marine environments is inferior to the other three alloys.

Comparison of Stress Corrosion Cracking Resistance

- 5056 aluminum alloy exhibits excellent resistance to stress corrosion cracking (SCC). The addition of manganese and chromium effectively enhances SCC resistance, improves the strength of the bulk metal and welds, and reduces the tendency for weld cracking.

- 5083 aluminum alloy has good corrosion resistance, it is prone to SCC. To avoid SCC, the operating temperature of 5083 alloy should not exceed 65℃, and its use in high-temperature, high-stress environments should be avoided.

- 5754 aluminum alloy is not sensitive to chloride SCC and is highly reliable in marine environments, exhibiting superior SCC resistance compared to 5083.

- 5052 aluminum alloy has moderate SCC resistance; special protection is required when used in high-temperature, high-stress environments.

Weldability and Corrosion Resistance

- All four alloys exhibit good weldability and can be welded using various methods such as argon arc welding and resistance welding. The weld strength after welding is close to that of the base metal, and the corrosion resistance is good. The weldability of 5056, 5754, and 5083 is particularly outstanding, with high weld joint strength and minimal decrease in corrosion resistance after welding, almost equivalent to that of the base metal.

Shipbuilding Application Scenarios

Based on their differences in corrosion resistance, the four alloys have different application scenarios in shipbuilding:

- 5056 Aluminum Alloy: Offers the best seawater corrosion resistance, suitable for components with special high corrosion resistance requirements such as ship rivets, cable sheaths, and high-corrosion-resistant wires, as well as heavy-duty structural components such as ship structures and offshore platforms.

- 5083 Aluminum Alloy: Offers the highest strength and excellent seawater corrosion resistance, suitable for heavy-duty structural components such as ship hulls and offshore platforms, as well as high-strength welding applications requiring high joint strength, such as ship parts and bridges.

- 5754 Aluminum Alloy: Offers balanced overall performance, good corrosion resistance, and good weldability, suitable for applications with medium strength requirements such as ship structures, pressure vessels, and transport tanks.

- 5052 Aluminum Alloy: Offers the lowest price and good formability, suitable for non-load-bearing components such as ship sheet metal parts, instrument brackets, and street light brackets, offering the best cost-performance ratio in freshwater or humid atmospheric environments.

Application

Marine and Shipbuilding Industry

5056 aluminum bar is favoured for its high strength and excellent seawater corrosion resistance. It is used in hull frames, deck fittings, and propeller shaft sleeves, ensuring durable, lightweight structures. Its good weldability enables strong joints in fuel tanks and superstructures. The bar withstands harsh marine conditions, reducing maintenance and enhancing longevity of ships and workboats.

Construction and Infrastructure

5056 aluminum bar is used where high strength, corrosion resistance, and durability are needed. It serves in structural frames, bridge components, and façade supports, especially in coastal or industrial areas. Its good weldability enables solid joints, while its lightweight nature eases handling and installation. The bar ensures long‑term performance and low maintenance in demanding construction and infrastructure projects.

Aerospace

5056 aluminum bar is valued in aerospace for its high strength, lightweight, and excellent fatigue resistance. It is used in aircraft structural brackets, fuel system components, and missile parts, where reliability under cyclic loads is crucial. Its good weldability and corrosion resistance ensure durable, long‑life assemblies. The bar helps reduce weight while maintaining performance and safety in demanding flight environments.

Cold Heading Applications

5056 aluminum bar is suited for cold heading due to its good strength, formability, and corrosion resistance. It is used to produce high‑strength fasteners, rivets, and bolts for marine, automotive, and aerospace hardware. Its ability to form complex shapes without cracking ensures reliable, durable joints. The bar’s performance in cold working processes makes it ideal for mass‑produced, high‑integrity fastening components.

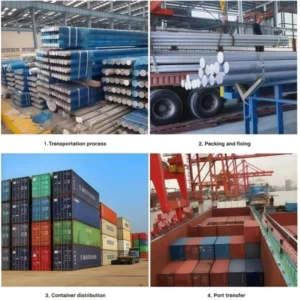

Package

| Packing | 1,Generaally package:Anti-water paper+strapped with min three strapping strips. |

| 2,Standard exporting package:Anti-water paper and plastic+covered by iron shrrt+strapped with min three strapping strips. | |

| 3,Excellent package:Anti-water paper and plastic film+covered by iron sheet+strapped with min three strapping strip+fixed on the iron or wooden pallets by strapping strips. | |

| Shipping | 1,Shipping by containers |

| 2,Shipping by bulk ship | |

| Custom | Customization is available upon request |

Why Choose Us?

Quality Assurance – All products comply with ASTM, ISO, ensuring high purity, uniformstructure, and stable performance.

Professional Supplier – Professional 5056 aluminum bar rod supplier in China. We have an advanced factory to ensure quality and efficiency.

Competitive Price – The mature supply chain system ensure that our products are highly competitive in cost and price.

Superior Quality – Quality supervision on whole process of production from raw materials, manufacturing, packaging, warehousing till container loading.

On-Time Delivery – The mature logistics management system and company self owned freight forwarder ensure that our OTD rate reaches 100%.