5052 Aluminum Bar

5052 Aluminum Bar is a non-heat-treatable, magnesium-rich (Al-Mg) alloyfrom the 5000 series—synonymous with superior corrosion resistance, exceptional formability, and reliable weldabilityfor applications exposed to harsh environments. With 2.2–2.8% magnesium (Mg) as the key alloying element, plus trace manganese (Mn ≤ 0.5%) and chromium (Cr ≤ 0.1%), 5052 strikes the perfect balance between moderate strength (190–260 MPa tensile)and ductility, making it a workhorse for marine, automotive, aerospace, and industrial sectors.

Corrosion Resistance and Weldability of HSTF 5052 Aluminum Bar

| Main Features | Property | Description |

| Corrosion Resistance | Seawater Corrosion Resistance | 5052 aluminum alloy can maintain good corrosion resistance in seawater, so HSTF 5052 aluminum rods are often used in marine engineering, ship structures and other environments. |

| Resistance to Industrial Atmospheric Corrosion | In an environment exposed to acidic, alkaline or humid air, 5052 aluminum alloy can still maintain a high level of corrosion resistance, so it is suitable for chemical equipment, storage tanks, etc. | |

| Surface Protection Layer | The oxide film of 5052 aluminum alloy can spontaneously form a protective oxide layer in most environments, which makes HSTF 5052 aluminum rods do not require additional anti-corrosion treatment in a variety of corrosive environments. | |

| Solderability | Welding Process Compatibility | HSTF 5052 aluminum rod can be welded by common welding methods such as MIG (Metal Inert Gas Welding), TIG (Tungsten Inert Gas Welding), etc. The welding process is smooth and easy to operate. |

| Strength and Corrosion Resistance After Welding | After welding, 5052 aluminum alloy can maintain good strength under appropriate welding conditions, and its corrosion resistance will not be significantly reduced, ensuring the long-term durability of the welded parts. | |

| Stable Performance of Heat-Affected Zone | During the welding process, the heat-affected zone (HAZ) of 5052 aluminum alloy shows good stability, and there will be no significant hardness reduction or crack formation in the heat-affected zone after welding. |

Our 5052 aluminum bar meet or exceed international standards, including ASTM B211/ASME SB211; ASTM B221/ASME SB221; AMS 4114/ISO AlMg2,5; AMS-QQ-A-225/7. Our quality management system ensures compliance with these standards and provides reliable, certified materials for your critical applications.

HSTF Aluminum is a high-quality 5052 aluminum rod bar supplier and manufacturer in China. We have large stock, factory direct price, quality assurance, fast delivery.

Specification

| Alloy | 5052 Alloy |

| Temper | O, H14, H18, H32, H34, H112 |

| Equivalent Names | UNS A95052, ISO AIMg2.5, Aluminium 5052, AA5052, Al5052 |

| Processing | heat-resistant, cold working, heat treatment, mechanical processing, welding |

| Surface Treatment | mill finish, anodized, bright, black, polished … |

| Size Range | 5052 aluminum round bar (5-600mm); 5052 aluminum flat bar (2-200mm); 5052 aluminum square bar, hexagonal bar opposite side distance (5-200mm) |

| Length | 1-6m; can be cut to any length. |

| 5052 Aluminum Hexagonal Bar | 2-100mm A/F, length can be cut |

| Standard | ASTM B211, ASME SB211, ASTM B221, ASME SB221, AMS 4114, ISO AlMg2,5, AMS-QQ-A-225/7 |

5052 Aluminum Bar Chemical Composition

| Element | Composition(%) |

| Aluminum (Al) | 95.8 – 97.7 |

| Magnesium (Mg) | 2.2 – 2.8 |

| Chromium (Cr) | 0.15 – 0.35 |

| Iron (Fe) | 0 – 0.4 |

| Silicon (Si) | 0 – 0.25 |

| Manganese (Mn) | 0 – 0.1 |

| Zinc (Zn) | 0 – 0.1 |

| Copper (Cu) | 0 – 0.1 |

| Residuals | 0 – 0.15 |

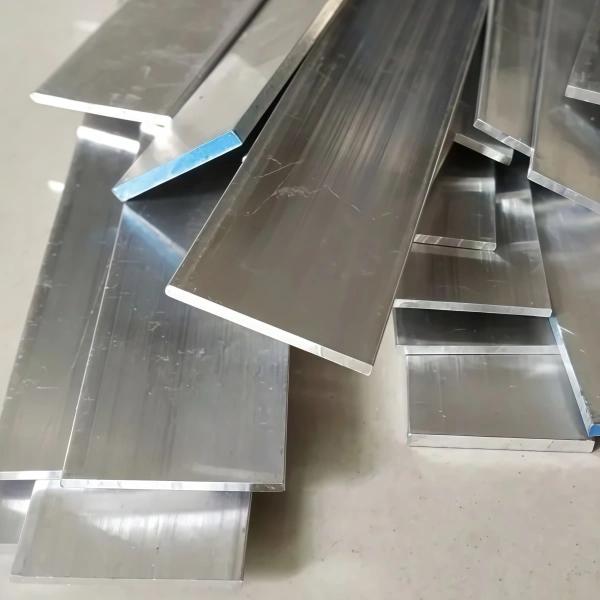

HSTF 5052 Aluminum Bar Products

5052 Cold Drawn Aluminum Bar

- Dimensional accuracy: Cold drawing process ensures high-precision dimensions and reduces tolerances.

- Surface quality: The surface is smooth and almost no subsequent processing is required, which is suitable for applications with strict requirements on appearance.

- Higher strength: It has higher strength and is suitable for parts bearing medium loads.

| 5052 cold drawn aluminum bar mechanical properties | |||||

| Temper | Diameter or thickness mm | Ultimate Tensile Strength R m /MPa | Yield Tensile Strength Rp0.2/MPa | Elongation at Break % | |

| A | A 50mm | ||||

| O | ≤50 | 170-220 | ≥65 | ≥22 | ≥25 |

| H14 | ≤30 | ≥235 | ≥180 | ≥5 | – |

| H18 | ≤10 | ≥265 | ≥220 | ≥6 | – |

| F | ≤100 | – | – | – | – |

5052 Extruded Aluminum Bar

- Shape flexibility: Extrusion processes can produce various complex cross-sections to meet different requirements.

- Uniform performance: Excellent surface finish and uniform mechanical properties make it stable and reliable in structural applications.

- Higher strength: Suitable for applications requiring high strength and structural stability.

| 5052 extruded aluminum bar mechanical properties | |||||

| Temper | Diameter (square rod, Hexagonal rod finger incision Circle diameter) /mm | Ultimate Tensile Strength R m /MPa | Yield Tensile Strength R p0.2/MPa | Elongation at Break % | |

| A(%) | A 50mm (%) | ||||

| H112 | ≤250 | ≥170 | ≥70 | – | – |

| O | 170-230 | ≥70 | ≥17 | ≥15 | |

5052 Hot Rolled Aluminum Bar

High-temperature hot rolling of 5052 aluminum rod bars can improve their ductility, strength, and toughness, while reducing internal stress and enhancing the overall mechanical properties of the material.

This makes them easier to process into large sizes and complex shapes.

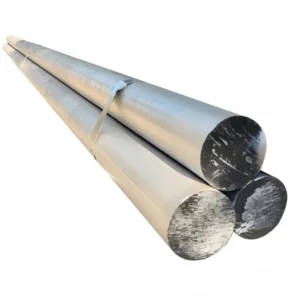

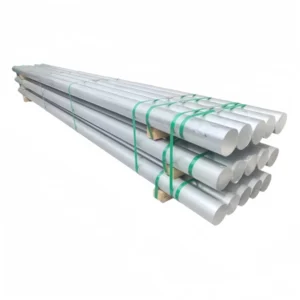

5052 Aluminum Round Bar

Compared with 5052 aluminum round bar, 5052 aluminum rod usually refers to a cylindrical aluminum material with a smaller diameter, ranging from a few millimeters to tens of millimeters. Due to its slender shape, aluminum rods are often used in applications that require a circular cross-section, such as precision mechanical parts and shaft components.

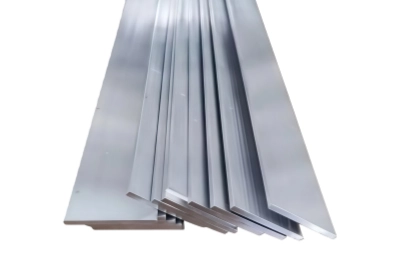

5052 Aluminum Flat Bar

5052 aluminum flat bar has a flat rectangular or square cross-section, suitable for manufacturing flat components and structural parts. It provides high strength and good bending resistance, and can withstand large loads. In terms of processing, it is easy to cut, bend and weld, which is convenient for application in various applications.

HSTF 5052 Aluminum Bar Stock

| Diameter (inch) | Diameter (Metric) | Weight (KG/Metre) |

| 3/8″ | (9.53mm) | 0.202 |

| 1./2″ | (12.7 mm) | 0.355 |

| 5/8″ | (15.88 mm) | 0.561 |

| 3/4″ | (19.05 mm) | 0.807 |

| 7/8″ | (22.23 mm) | 1.097 |

| 1″ | (25.4 mm) | 1.419 |

| 1.1/8″ | (28.58 mm) | 1.816 |

| 1.1/4″ | (31.75 mm) | 2.241 |

| 1.3/8″ | (34.93 mm) | 2.690 |

| 1.1/2″ | (38.1 mm) | 3.226 |

| 1.5/8″ | (41.28 mm) | 3.747 |

| 1.3/4″ | (44.45 mm) | 4.360 |

| 2″ | (50.8 mm) | 5.675 |

| 2.1/4″ | (57.15 mm) | 7.190 |

| 2.1/2″ | (63.5 mm) | 8.867 |

| 2.3/4″ | (69.85 mm) | 10.730 |

| 3″ | (76.2 mm) | 12.769 |

| 3.1/4″ | (82.5 mm) | 14.986 |

| 3.1/2″ | (88.9 mm) | 17.380 |

| 3.3/4″ | (95.25 mm) | 20.165 |

| 4″ | (101.6 mm) | 22.700 |

| 4.1/4″ | (107.95 mm) | 25.627 |

| 4.1/2″ | (114.3 mm) | 28.730 |

| 5″ | (127 mm) | 35.469 |

| 5.1/4″ | (133.35 mm) | 39.105 |

| 5.1/2″ | (139.7 mm) | 42.994 |

| 6″ | (152.4 mm) | 51.076 |

| 6.1/2″ | (165.1 mm) | 59.943 |

| 7″ | (177.8 mm) | 69.650 |

| 8 “ | (203.2 mm) | 90.802 |

The above are some stock sizes for HSTF 5052 aluminum bars. Our stock is frequently updated, and if you cannot find a product that suits your needs, you can communicate with our sales staff regarding specific products. All lengths can be cut.

Contact Us NowApplication

Marine Engineering

- Hull bracing bars: corrosion-resistant, seawater-durable for structural support in boats.

- Deck fittings mounts: strong, rust-proof bars fix cleats, rails, and accessories.

- Fuel tank stiffeners: formable bars reinforce tanks, resisting fuel and moisture corrosion.

Automotive Industry

- Body trim brackets: lightweight, corrosion-proof bars hold exterior panels and moldings.

- Fuel system supports: durable bars secure lines and tanks against road chemicals.

- Interior panel frames: formable bars shape lightweight, rust-resistant cabin components.

Architecture & Construction

- Curtain wall mullions: strong, weather-resistant bars frame facades and cladding.

- Window frame stiffeners: corrosion-proof bars boost durability in coastal buildings.

- Canopy support bars: formable, lightweight bars build outdoor roof structures.

Industrial Equipment

- Chemical tank supports: corrosion-resistant bars handle mild acids and alkalis safely.

- Conveyor guide bars: formable, durable bars align materials in humid environments.

- Enclosure framing: rust-proof bars build protective cases for outdoor machinery.

Package

| Packing | 1,Generaally package:Anti-water paper+strapped with min three strapping strips. |

| 2,Standard exporting package:Anti-water paper and plastic+covered by iron shrrt+strapped with min three strapping strips. | |

| 3,Excellent package:Anti-water paper and plastic film+covered by iron sheet+strapped with min three strapping strip+fixed on the iron or wooden pallets by strapping strips. | |

| Shipping | 1,Shipping by containers |

| 2,Shipping by bulk ship | |

| Custom | Customization is available upon request |

Why Choose Us?

Quality Assurance – All products comply with ASTM, EN, ISO, ensuring high purity, uniformstructure, and stable performance.

Professional Supplier – Professional 5052 aluminum rod bar supplier in China. We have an advanced factory to ensure quality and efficiency.

Competitive Price – The mature supply chain system ensure that our products are highly competitive in cost and price.

Superior Quality – Quality supervision on whole process of production from raw materials, manufacturing, packaging, warehousing till container loading.

On-Time Delivery – The mature logistics management system and company self owned freight forwarder ensure that our OTD rate reaches 100%.

FQA

Yes,we promise to provide best quality products and delivery on time .Honesty is our company’s tenet.

We can provide the sample for customer with free, but the customer account will cover the courier freight.

The manufacturing process produces each piece in certified workshops. Our inspection team checks them piece by piece. This is done according to national QA/QC standards. We also could issue the warranty to customer to guarantee the quality.

We specialize in steel business for years. Our headquarters is in Liaocheng Economic Zone. This is in Shandong province. You are welcome to investigate in any way. By all means, you could place an order. Use trade assurance for your payment security.

Our team will check email and fax within 24 hours. Meanwhile, these platforms remain online 24 hours. They include Facebook, Skype, WeChat, and WhatsApp. Please send us your requirements and order information. Provide the specification details. These include steel grade, size, and quantity. Also include the destination port. We will work out the best price soon.