3003 Aluminum Bar

3003 aluminum rod bar is a commonly used product in the aluminum-manganese alloy series. This material has excellent anti-rust properties and is also called anti-rust aluminum bar with the addition of manganese alloy element. It is often used for processing parts and components that need good formability, high corrosion resistance and good weldability. Suitable for a wide range of applications, including decoration, packaging, construction, transportation, electronics, aerospace, defense, and more.

-

- Moderate Strength: About 20% stronger than 1100 series aluminum, suitable for applications that do not require extremely high strength.

- Excellent Corrosion Resistance: Provides good resistance to atmospheric and chemical corrosion, making it ideal for use in outdoor and corrosive environments.

- Outstanding Workability: Easy to machine, weld, and braze, making it suitable for producing various metal products and structural components.

- Good Weldability: Compatible with various welding methods such as MIG and TIG, offering reliable weldability without requiring special treatment.

- High Thermal Conductivity: Capable of effectively dissipating heat, making it ideal for applications such as heat exchangers and electronic devices.

3003 Extrusion Aluminum Bar

Temper: F, O, H111, H112

DIA: 0.4″-16″(10-420mm)

Spec:ASTM B221, EN 755

3003 Cold Finished Aluminum Bar

Temper: H12, H14, H16, H18

DIA: 0.125″-8″ (3-200mm)

Spec: AMS-QQ-A-225/2, ASTM B211

3003 Aluminum Cast Billets Bar

Temper: F

DIA: 4.8″-53″ (124-1350mm)

For subsequent extrusion production

Our 3003 aluminum rod bar meet or exceed international standards, including AMS-QQ-A-225/2, EN 755, EN 754, ASTM B221, ASTM B211. Our quality management system ensures compliance with these standards and provides reliable, certified materials for your critical applications.

HSTF Aluminum is a high-quality 3003 aluminum rod bar supplier and manufacturer in China. We have large stock, factory direct price, quality assurance, fast delivery.

Specification

| Alloy | 3003 Aluminum |

| Equivalent Names | UNS A93003,EN AW-3003,AlCuMg2,AlCu4Mg,AA3003,3.0517 |

| Temper | F, O, H111, H112, H12, H14, H16, H18 |

| Types | Square, Round, Hex, Flat |

| Processing Methods | Extrusion, Cold Finished, Casting |

| Specifications | AMS-QQ-A-225/2, EN 755, EN 754, ASTM B221, ASTM B211 |

3003 Aluminum Bar Chemical Composition

| Element | EN AW-3003 |

| Si | 0.60 |

| Fe | 0.70 |

| Cu | 0.05-0.20 |

| Mn | 1.0-1.5 |

| Mg | – |

| Cr | – |

| Zn | 0.10 |

| Ti | – |

| Others (Each) | 0.05 |

| Others (Total) | 0.15 |

| Al | Rem |

3003 Aluminum Bar Physical Properties

| Physical Property | Value |

| Density | 2.73g/cm³ |

| Melting Point | 640-650 °C |

| Thermal Expansion | 23 µm/m-K |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 180 W/m.K |

| Electrical Conductivity | 44% IACS |

3003 Aluminum Bar Thermal Properties

| Thermal Properties | Value |

| Latent Heat of Fusion | 400 J/g |

| Maximum Temperature: Mechanical | 180 °C |

| Specific Heat Capacity | 900 J/kg-K |

| Thermal Conductivity | 180 W/m-K |

| Thermal Expansion | 23 µm/m-K |

HSTF 3003 Aluminum Bar Temper

3003 O/F Aluminum Rod Bar

3003-O aluminum bars are in their softest state and have the highest ductility compared to other 3003 aluminum variants. They are particularly suitable for applications requiring high-volume forming and bending without cracking. H111 aluminum bars, after cold working, have slightly higher strength than O-tempered bars while maintaining good formability.

3003 F/H112 Aluminum Rod Bar

The 3003 H112 aluminum rod is similar to the F temper but allows for limited strain hardening or heat treatment under specific conditions. It maintains good workability with moderate strength, making it suitable for applications requiring good formability and corrosion resistance, such as construction, pipelines, and storage tanks.

3003 H12 Aluminum Rod Bar

3003 H12 aluminum rod undergoes moderate strain hardening, with its strength falling between the O temper (annealed) and fully hard (H18) states. It provides moderate strength and good formability, ideal for applications that require moderate strength and further processing, such as pipelines, chemical equipment, and storage tanks.

3003 H14/H16 Aluminum Rod Bar

3003 H14/H16 aluminum rods undergo more significant strain hardening, with strength between the annealed (O temper) and fully hard (H18) states. They offer good corrosion resistance and higher strength while maintaining good formability, making them suitable for medium-strength applications like metal products, chemical equipment, and tank containers.

3003 H18 Aluminum Rod Bar

The H18 temper represents the fully hardened state of 3003 aluminum bars, achieving maximum strength through complete strain hardening. Due to its high strength and low ductility, H18 aluminum bars are ideal for applications requiring no further processing, such as building materials and environments with high corrosion resistance requirements.

3003 H14 Aluminum Rod Bar

3003 H14 aluminum wire undergoes strain hardening treatment, resulting in medium strength, good formability, and corrosion resistance. It is widely used in the automotive industry, fastener manufacturing, and electronic equipment fields, and is especially suitable for manufacturing automotive brake rivets.

HSTF 3003 Aluminum Bar Shape

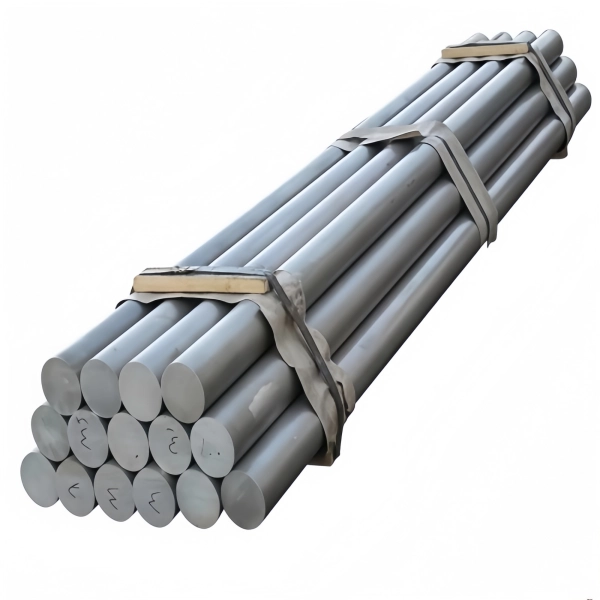

3003 Aluminum Round Bar

Diameter: 5-420mm

The round-section aluminum rod is the most commonly used shape. It can be extruded into microchannel aluminum tubes and custom decorative parts. It is typically used in heat exchangers, chemical equipment, and tank fittings.

3003 Aluminum Square Bar

Size: 10x10mm to 200x200mm

The square-section aluminum bar offers good machinability and weldability. It is suitable for a wide range of industrial fields such as construction, chemical processing, food processing, and machinery manufacturing.

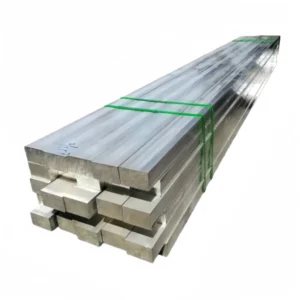

3003 Aluminum Flat Bar

Size: 10x12mm to 100x250mm

The rectangular-section aluminum bar provides moderate strength, good corrosion resistance, and easy workability. It is commonly used in industrial applications that require corrosion resistance, formability, and adequate strength, such as construction, food processing, chemical equipment, and storage systems.

Application

Aerospace

Due to its good formability, excellent corrosion resistance, and high thermal conductivity, it is suitable for aircraft and spacecraft heat exchange systems, cooling pipes, liquid storage tanks, fuel pipes, gas processing equipment, and other non-load-bearing components.

Heat Exchangers

With a thermal conductivity of 180 W/m-K, it quickly transfers heat, improving heat transfer efficiency, and making it ideal for heat exchanger applications such as automotive radiators, air conditioning systems, air conditioner heat exchangers, and industrial heat exchangers.

Chemical Equipment

Storage Tanks

Widely used in applications requiring safe storage and high-strength sealing, such as food processing tanks, chemical tanks, and liquid storage tanks. The addition of manganese helps maintain stability and resist corrosion when in contact with liquid chemicals.

Package

| Packing | 1,Generaally package:Anti-water paper+strapped with min three strapping strips. |

| 2,Standard exporting package:Anti-water paper and plastic+covered by iron shrrt+strapped with min three strapping strips. | |

| 3,Excellent package:Anti-water paper and plastic film+covered by iron sheet+strapped with min three strapping strip+fixed on the iron or wooden pallets by strapping strips. | |

| Shipping | 1,Shipping by containers |

| 2,Shipping by bulk ship | |

| Custom | Customization is available upon request |

Why Choose Us?

- Price Advantage: We support both retail and bulk purchases for metal distributors, offering discounts and rebate policies for B2B customers. Our pricing is transparent, ensuring a competitive advantage with equivalent-quality aluminum rods.

- Fast Delivery: With over 10,000 tons of stock, standard sizes can be matched with existing inventory, ensuring quick shipment. Our advanced equipment and expert team help reduce lead times and provide efficient logistics for on-time delivery.

- High-Quality Products: We use premium aluminum rod billets, employing precise alloying and heat treatment processes to optimize the product’s strength and ductility. Our uniform cooling and annealing processes ensure high tensile strength and superior performance.

- Excellent Grain Control: Produced via reverse extrusion, we control the cooling rate and homogenization process. The grain ring is typically controlled to ≤0.5mm, reducing defects and improving material consistency.

- Comprehensive Quality Testing: We strictly implement multiple inspection processes, including tensile strength, elongation performance, ultrasonic testing, and metallographic inspection, ensuring that our aluminum rods meet AMS, EN, and NADCAP certification standards.

- Customer Service: We provide full after-sales support to resolve customer concerns. Our experienced technical team offers professional consultation and guidance, ensuring an excellent customer service experience.

FQA

Yes,we promise to provide best quality products and delivery on time .Honesty is our company’s tenet.

We can provide the sample for customer with free, but the customer account will cover the courier freight.

The manufacturing process produces each piece in certified workshops. Our inspection team checks them piece by piece. This is done according to national QA/QC standards. We also could issue the warranty to customer to guarantee the quality.

We specialize in steel business for years. Our headquarters is in Liaocheng Economic Zone. This is in Shandong province. You are welcome to investigate in any way. By all means, you could place an order. Use trade assurance for your payment security.

Our team will check email and fax within 24 hours. Meanwhile, these platforms remain online 24 hours. They include Facebook, Skype, WeChat, and WhatsApp. Please send us your requirements and order information. Provide the specification details. These include steel grade, size, and quantity. Also include the destination port. We will work out the best price soon.