2219 Aluminum Bar

2219 Aluminum Bar is a high-strength, heat-treatable aluminum-copper alloyfrom the 2000 series, renowned for its exceptional strength at elevated temperatures, superior weldability, and excellent performance in cryogenic environments. With a copper content of 5.8–6.8%and additions of manganese (0.2–0.4%), vanadium (0.05–0.15%), and zirconium (0.1–0.25%), this alloy delivers outstanding mechanical propertieswhile maintaining good fracture toughness and stress corrosion resistance. Widely used in aerospace, automotive manufacturing, and other fields.

| Characteristics | Description |

High-Temperature Resistance |

The 2219 Aluminum Alloy Round Bar performs excellently under extreme temperature conditions, maintaining mechanical integrity in environments ranging from -452°F to 600°F (-269°C to 315°C). This characteristic makes it particularly suitable for applications that are highly sensitive to temperature variations, such as spacecraft structures, rocket engine combustion chamber liners, and high-temperature liquid transport systems. Its high-temperature strength comes from its primary alloying element, copper (Cu), ensuring excellent structural stability and creep resistance in high-temperature environments while maintaining sufficient toughness at extremely low temperatures, making it suitable for cryogenic propellant storage tanks. |

Corrosion Resistance |

The 2219 Aluminum Round Alloy Bar has moderate corrosion resistance and is particularly susceptible to corrosion in marine or high-humidity environments. Therefore, additional surface treatments are usually required to enhance its corrosion resistance. Common methods include anodizing, electrophoretic coating, or chromate treatment to form a dense protective film that improves oxidation resistance. These treatment processes make it suitable for aircraft fuselage structures, fuel tanks, and spacecraft components, ensuring stable mechanical properties and structural integrity over long service periods. |

Fatigue Resistance |

The 2219 Aluminum Alloy Round Bar exhibits excellent fatigue resistance, allowing it to withstand long-term cyclic loads without fatigue failure. This property is crucial in aerospace applications, especially in aircraft skins, wing structures, and landing gear attachments that endure repeated stress, effectively extending their service life. Its high fatigue resistance stems from its uniform microstructure and well-balanced alloy composition, providing better crack propagation resistance under cyclic loads, ensuring reliability and safety in high-strength working environments. |

Our 2219 aluminum bar conforms to multiple international standards, including ASTM B221, AMS 4162, AMS QQ-A-200/31, EN 573, EN 755. We can also provide material testing certificates and third-party inspection reports upon request to ensure quality assurance for your critical applications. Our commitment to quality means you can rely on our 2219 aluminum bar to meet the stringent requirements of your projects.

HSTF Aluminum is a high-quality 2219 aluminium bar supplier and manufacturer in China. We have large stock, factory direct price, quality assurance, fast delivery.

Specification

| Alloy | 2219 Aluminum Alloy |

| Equivalent Name | A92219, AlCu6Mn, EN AW-2219, DIN 3.1325, AMS 4162 |

| Temper | O, T6, T8, T851, T8511 |

| Types | Square, Round, Hex, Flat in Black & Bright Finish |

| Length | 1-6m, Random, Fix & Cut Length or as per clients’ requirement |

| Surface | Bright, Polish & Black |

| Packaging | 1. Plastic or kraft paper packaging with moisture desiccants.

2. Mounted on wooden pallets, reinforced with steel straps, and provided with fumigation certificates. 3. Packaging can be tailored to other customer requirements. |

| Standards | EN 573, EN 755, ASTM B221, AMS 4162, AMS QQ-A-200/31 |

2219 Aluminum Chemical Composition

| Element | Composition % |

| Cu | 5.8-6.8 |

| Fe | 0.3 |

| Mg | 0.02 |

| Mn | 0.2-0.4 |

| Si | 0.2 |

| Ti | 0.02-0.10 |

| V | 0.05-0.15 |

| Zn | 0.1 |

| Zr | 0.1-0.25 |

| Each | 0.05 |

| Total | 0.15 |

2219 Aluminum Bar Physical Properties

| Property | Value |

| Density | 2.84 g/cm³ |

| Melting Point | 543 – 643 °C |

| Thermal Conductivity | 120 W/m-K |

| Modulus of Elasticity | 73.1 GPa |

| Electrical Resistivity | 0.00000570 ohm-cm |

2219 Aluminum Bar Type

HSTF offers a full range of production types and sizes to meet your critical needs.

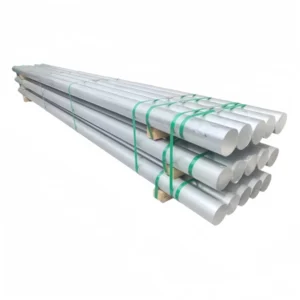

2219 T8511 Extruded Aluminum Round Bar

Diameter: Φ5-420mm 丨 Length: 1000-6000mm

2219-T8511 extruded aluminum round bar is manufactured through precision extrusion processes. Aerospace applications widely use it for structural components exposed to elevated temperatures, such as fuel tanks and booster systems.

2219 T8511 Extruded Aluminum Square Bar

Diameter: 5-200mm 丨 Length: 1000-6000mm

2219-T8511 extruded aluminum square bars feature a square cross-section produced through the extrusion of EN AW-2219 aluminum. They offer high strength, excellent weldability, and good fracture toughness, especially in high-temperature environments. These properties make them suitable for aerospace structures, precision engineering, and other applications requiring both strength and thermal stability.

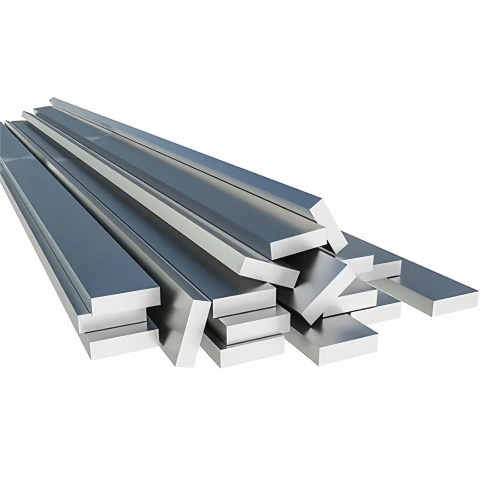

2219 Extruded Aluminum Flat Bar

Diameter: 2-100mm 丨 Length: 1000-6000mm

ASME SB B221 AL 2219 T8511 Flat Bar is produced through precision extrusion processes and features a flat rectangular cross-section. Its high strength, excellent weldability, and performance at elevated temperatures make it widely used in aerospace structures, cryogenic tanks, and other high-performance engineering applications.

2219 Extruded Aluminum Hex Bar

Diameter: 5-200mm 丨 Length: 1000-6000mm

2219 extruded aluminum hexagonal bar is formed using advanced extrusion processes and features a hexagonal cross-sectional shape. Its high strength, excellent weldability, and thermal stability make it well-suited for demanding applications in aerospace, precision components, and high-temperature structural assemblies.

2219 T8511 Aerospace Aluminum Round Bar

Diameter: Φ100-350mm 丨 Length: 1000-6000mm

UNS A92219 T8511 aerospace aluminum round bars are high-strength aluminum bars engineered for aerospace applications, offering excellent performance at elevated temperatures. They are certified to meet stringent aerospace standards such as AMS 4162, UNS A92219, and QQ-A-200/31.

2219 Aluminum Forged Round Bar

Diameter: Φ100-650mm 丨 Length: 1000-6000mm

Our factory uses precision forging technology to produce AMS 4162 AA2219-T8511 forged round bars, which are forged under high pressure to optimize their internal structure. 2219 forged aluminum bars possess excellent strength, good dimensional stability, and outstanding fatigue resistance, making them ideal materials for aerospace components and high-performance engineering applications.

2219 Aluminum Cast Round Bar

Diameter: Φ124-1350mm

Length: 1000-6000mm

Manufacturers primarily use 2219 aluminium cast round bar for subsequent extrusion billets, with a maximum diameter of up to 1350mm.

Application

2219 Aluminum Bar for Aerospace

Widely used in key components such as aircraft fuselage, wing structure and fuel tank.

- Fuselage longerons: high-strength bars bear pressurization and flight loads in longitudinal structures.

- Fuel tank bulkheads: weldable, corrosion-resistant bars form leak-proof, pressure-resistant partitions.

- Wing root fittings: tough bars join wings to fuselage, withstanding cyclic stress.

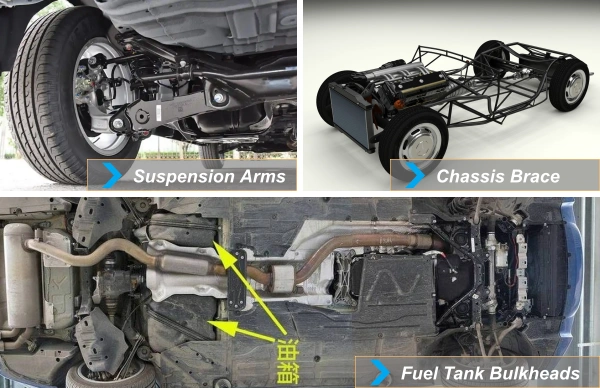

2219 Aluminum Bar for Automotive

Offers high strength, excellent weldability, and corrosion resistance, suiting demanding automotive roles.

- High‑strength suspension arms: lightweight bars reduce unsprung mass while withstanding driving stresses.

- Fuel system components: corrosion‑resistant bars ensure durable, leak‑proof fuel tank and line parts.

- Racing chassis braces: tough bars enhance rigidity and crash safety in high‑performance vehicles.

2219 Aluminum Bar for Marine Industry

By balancing strength, elasticity and processability, 2219 aluminum rods have become the preferred solution for modern Marine engineering.

- Hull stringers: lightweight, corrosion‑resistant bars stiffen aluminum hulls against wave loads.

- Deck support frames: strong bars bear deck loads and resist saltwater degradation.

- Offshore platform braces: tough bars reinforce structures in harsh marine environments.

Why Choose Us?

Quality Assurance – All products comply with ASTM, EN, ISO, RoHS, ensuring high purity, uniformstructure, and stable performance.

Professional Supplier – Professional 2219 aluminum bar suppliers in China. We have an advanced factory to ensure quality and efficiency.

Competitive Price – The mature supply chain system ensure that our products are highly competitive in cost and price.

Superior Quality – Quality supervision on whole process of production from raw materials, manufacturing, packaging, warehousing till container loading.

On-Time Delivery – The mature logistics management system and company self owned freight forwarder ensure that our OTD rate reaches 100%.

FQA

Yes,we promise to provide best quality products and delivery on time .Honesty is our company’s tenet.

We can provide the sample for customer with free, but the customer account will cover the courier freight.

The manufacturing process produces each piece in certified workshops. Our inspection team checks them piece by piece. This is done according to national QA/QC standards. We also could issue the warranty to customer to guarantee the quality.

We specialize in steel business for years. Our headquarters is in Liaocheng Economic Zone. This is in Shandong province. You are welcome to investigate in any way. By all means, you could place an order. Use trade assurance for your payment security.

Our team will check email and fax within 24 hours. Meanwhile, these platforms remain online 24 hours. They include Facebook, Skype, WeChat, and WhatsApp. Please send us your requirements and order information. Provide the specification details. These include steel grade, size, and quantity. Also include the destination port. We will work out the best price soon.