2024 CF Aluminum Bar

2024 Cold Finished Aluminum Bar is a high-performance, heat-treatable alloy renowned for its exceptional strength-to-weight ratio and excellent machinability. Primarily composed of copper, magnesium, and manganese, the 2024 alloy is a cornerstone material for high-stress applications. The cold rolling process enhances its mechanical properties, resulting in superior dimensional accuracy, a smooth surface finish, and increased strength compared to standard hot-rolled bars.

Advantage |

Description |

|

High Strength |

One of the main characteristics of 2024 aluminum bar is its high strength-to-weight ratio. |

|

Good Fatigue Resistance |

This alloy is known for its excellent fatigue resistance, making it ideal for applications subjected to cyclic loads. |

|

Corrosion Resistance |

The 2024 aluminum bar is easy to machine, especially in the T3 condition. |

|

Moderate Corrosion Resistance |

The corrosion resistance of 2024 aluminum is lower than that of some other aluminum alloys, such as 6061. It is typically used with protective coatings or anodizing to enhance its corrosion resistance, especially in harsh environments. |

|

Heat Treatable |

2024 aluminum can be heat treated to further enhance its mechanical properties. Typical heat treatment conditions for 2024 include T3 (solution heat-treated and cold worked) and T4 (solution heat-treated and naturally aged). |

|

Ductility |

The 2024 CF Aluminum Bar has moderate ductility but is not as easily formable as other aluminum alloys like 6061. |

Our 2024 cold finished aluminum bar conform to international standards, including ASTM B211, AMS 4120, QQ-A-225/8, EN 573-3, and ISO 6361. We also provide Material Testing Certificates (MTC) and third-party inspection reports upon request to ensure quality assurance for your critical applications. Our cold-rolled products are manufactured in facilities that maintain stringent quality control standards to ensure the dimensional accuracy, mechanical properties, and surface quality of our precision cold-rolled aluminum.

HSTF Aluminum is a high-quality 2024 aluminum bar supplier and manufacturer in China. We have large stock, factory direct price, quality assurance, fast delivery.

Specification

| Product | 2024 Cold Finished Bar |

| Typical Tempers | T3, T4, T6, T651 (cold rolled variants) |

| Diameter Range | 3mm – 150mm (custom diameters available) |

| Length | 1m – 6m (or as per customer requirement) |

| Aluminum Content | 90.7% – 94.7% |

| Density | 2.78 g/cm³ (0.101 lb/in³) |

| Tensile Strength (T6 temper) | 470 MPa (68,000 psi) minimum |

| Yield Strength (T6 temper) | 325 MPa (47,000 psi) minimum |

| Elongation (T6 temper) | 10% – 12% (varies by diameter) |

| Electrical Conductivity | 30% IACS (International Annealed Copper Standard) |

| Thermal Conductivity | 121-138 W/m·K (approximate) |

| Melting Range | 500°C – 635°C (932°F – 1175°F) |

| Cold Rolling Reduction | Typically 10-30% reduction from hot rolled state |

| Surface Finish | Smooth, uniform finish with improved flatness and straightness |

| Corrosion Resistance | Moderate (enhanced in T3/T4 tempers or with protective coatings) |

| Machinability | Excellent (particularly in harder tempers) |

| Weldability | Fair (requires special techniques and filler materials) |

| Standards Compliance | ASTM B211, AMS 4120, QQ-A-225/8, EN 573-3, ISO 6361 |

2024 Aluminum Bar Chemical Composition

| Element | Percentage |

| Aluminum | 90.7% – 94.7% |

| Chromium | 0.1% (Max) |

| Copper | 3.8% – 4.9% |

| Iron | 0.5% (Max) |

| Magnesium | 1.2% – 1.8% |

| Manganese | 0.3% – 0.9% |

| Silicon | 0.5% (Max) |

| Zinc | 0.25% (Max) |

2024 Cold Finished Aluminum Bar Temper Type

To meet diverse performance and processing requirements, we supply 2024 aluminum bar in various standard tempers. Each temper combines strength, ductility, and machinability, making it suitable for various structural, aerospace, and precision engineering applications.

2024 T4 CF Aluminum Bar

The 2024 T4 CF aluminum bar is solution treated and naturally aged, offering good formability and some strength. It is commonly used for parts that require further processing. This condition aluminum bar has good machinability, suitable for various subsequent processing techniques, such as forming, cutting, and extrusion, making it ideal for manufacturing aerospace or other industrial components that need further processing. The T4 condition aluminum bar finds wide use in light load applications that require additional processing.

2024 T351 CF Aluminum Bar

The 2024 T351 CF aluminum bar is solution treated, cold worked (cold rolled), and naturally aged. This aluminum bar offers high strength and good mechanical properties, especially suitable for structural parts in aerospace that must bear high loads. The T351 condition aluminum bar has a certain balance of toughness and strength, making it suitable for applications requiring additional machining or welding. Its surface quality is usually good, meeting the requirements of complex structural designs.

2024 T6 CF Aluminum Bar

2024 T6 CF aluminum bar is solution treated and artificially aged, significantly enhancing its strength. The T6 condition aluminum bar offers excellent tensile strength and good fatigue resistance, making it suitable for applications that require high strength, particularly in aerospace where components face extreme working conditions. Its enhanced strength makes the T6 condition aluminum bar an ideal choice for critical components requiring high strength, low weight, and reliable performance, widely used in aircraft fuselage, wing spars, and other key load-bearing areas.

If you’re unsure which tempering grade is best for your application, our technical team can help you select the appropriate grade and processing conditions. Contact us for expert advice, data sheets, or custom supply options tailored to your project.

2024 CF Aluminum Bar Type

2024 CF Aluminum Round Bar

The 2024 CF aluminum round bar is provided in a circular cross-section, suitable for applications that require high strength and excellent mechanical properties, especially in aerospace and other high-demand fields. Due to their symmetrical round structure, round bars are ideal for rotating parts, machining, and components that bear uniform loads. They provide uniform strength and fatigue resistance, and they commonly serve for manufacturing shafts, rods, connectors, etc.

2024 CF Aluminum Square Bar

2024 CF aluminum square bars have four equal sides, suitable for applications that require precise dimensions and diagonal strength. The square bar form provides greater stability and precision, and it finds common use for mechanical structural components, frames, brackets, and applications that require precise cutting. They are common in aerospace and industrial fields, especially when parts need to mate precisely with other components, making square bars an ideal choice.

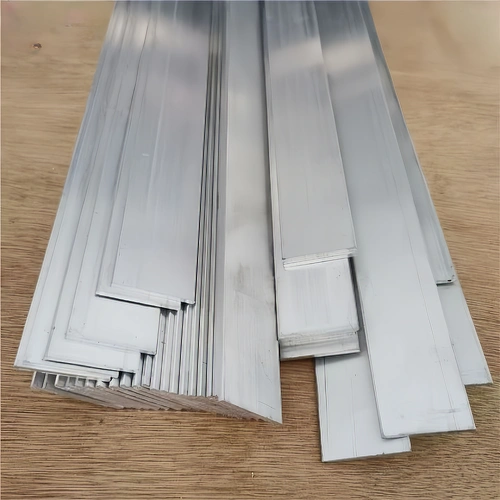

2024 CF Aluminum Flat Bar

2024 CF aluminum flat bars have a wide, flat cross-section. This makes them suitable for applications requiring large surface contact. They are also ideal for structural support. Their excellent machinability makes them commonly used. They are used to manufacture large structural components. These include support beams and foundation frames. They are also used for other parts. These parts require a flat surface. Due to their uniform cross-section, flat bars are ideal as templates, rails, supports, or base structures for installation.

2024 CF Aluminum Hexagonal Bar

2024 CF aluminum hexagonal bars have six symmetrical edges, suitable for applications that require unique geometries or efficient space utilization. The hexagonal structure provides greater stability. This is when bearing forces in different directions. It finds wide use in mechanical manufacturing. It is also used in aerospace components. Additionally, it is used for parts requiring extra torsional resistance. Hexagonal bars also commonly serve for manufacturing parts with special shape requirements, such as nuts, connectors, etc.

Application

Aerospace & Aviation

Due to its high strength, low weight, and excellent fatigue resistance, 2024 cold finished aluminum bars find wide use in aircraft fuselages, wings, skins, and other structural components. Common applications include:

- Aircraft fuselage frames

- Aircraft wing beams and support structures

- Aircraft surface skins and stiffeners

- Aircraft landing gear brackets

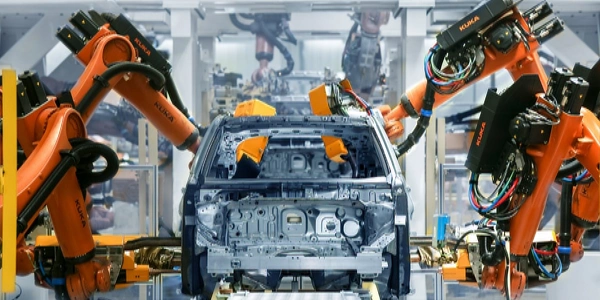

Automotive Industry

- High-performance pistons: cold finished bars offer precise dimensions and smooth surface, enhancing combustion chamber sealing and heat dissipation in racing engines.

- Transmission gears: bars’ high strength and fatigue resistance ensure durable, smooth shifting in manual and dual-clutch gearboxes under high torque.

- Suspension uprights: cold finished bars provide consistent mechanical properties, delivering lightweight yet rigid support for wheels in sports cars and EVs.

Defense & Military

- Armored vehicle reinforcements: high strength and precision shape lightweight frame and armor‑support elements, balancing protection and mobility.

- Ordnance mounting brackets: accurate dimensions ensure secure, load‑bearing attachment for bombs, missiles, and ejector racks.

- Communication/radar frames: stable grain structure and surface quality maintain alignment and signal integrity in harsh conditions.

Precision Components

- Fasteners: uniform strength and fine surface finish produce bolts and studs meeting exact torque and fatigue specs for aerospace and motorsport.

- Instrument mounts: precision dimensions enable distortion‑free housings for targeting systems, sensors, and avionics.

- Robotics joints: tight tolerances and smooth finish allow accurate, low‑backlash motion components in high‑precision manipulators.

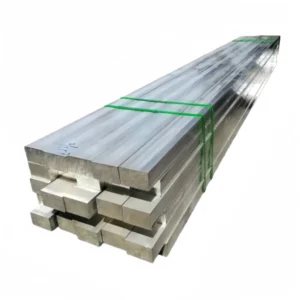

Packaging

- Inner protection: We wrap each aluminum rod in PE film, with optional paper, cardboard, or foam layers to resist moisture and scratches.

- Bundle securing: The packaging process bundles and reinforces aluminum rods with steel or PET straps, with protective padding to prevent loosening and abrasion.

- Outer packaging: We pack bulk orders in sturdy wooden crates or pallets, with optional export-grade fumigation and moisture-proof lining for compression and shock resistance.

Why Choose Us?

1. Premium Quality Cold Rolled Products: HSTF specialize in 2024 cold finished aluminum bar manufactured to the highest standards, ensuring you receive materials with the precise dimensional accuracy, surface quality, and mechanical properties your critical applications demand.

2. Extensive Size Range: HSTF offer 2024 cold finished aluminum bars in diameters from 3mm to 150mm, with custom sizes available to meet your specific requirements, including specialty diameters for unique applications.

3. Multiple Temper Options: Our inventory includes 2024 cold finished aluminum bar in various tempers (T4, T6, T351) specifically developed for cold rolled applications, allowing you to select the optimal combination of strength, workability, and corrosion resistance.

5. Global Logistics Expertise: With optimized packaging and shipping processes, we ensure your 2024 cold finished aluminum bars arrive in perfect condition worldwide, with competitive international shipping rates and comprehensive customs documentation support.

6. Technical Consultation: Our experienced metallurgists and engineers provide expert guidance on material selection, temper recommendations, and application considerations to help you choose the optimal cold rolled aluminum solution for your specific performance requirements.

7. Custom Processing Capabilities: In addition to standard 2024 cold finished aluminum bar, we offer customization options including cutting to length, specific tolerances, and special finishes to meet your exact specifications, reducing your processing requirements and lead times.

8. Competitive Pricing: By leveraging our direct sourcing capabilities and volume purchasing power, we offer premium quality 2024 cold finished aluminum bar at competitive prices that deliver exceptional value for your precision applications.

FQA

Yes,we promise to provide best quality products and delivery on time .Honesty is our company’s tenet.

We can provide the sample for customer with free, but the customer account will cover the courier freight.

The manufacturing process produces each piece in certified workshops. Our inspection team checks them piece by piece. This is done according to national QA/QC standards. We also could issue the warranty to customer to guarantee the quality.

We specialize in steel business for years. Our headquarters is in Liaocheng Economic Zone. This is in Shandong province. You are welcome to investigate in any way. By all means, you could place an order. Use trade assurance for your payment security.

Our team will check email and fax within 24 hours. Meanwhile, these platforms remain online 24 hours. They include Facebook, Skype, WeChat, and WhatsApp. Please send us your requirements and order information. Provide the specification details. These include steel grade, size, and quantity. Also include the destination port. We will work out the best price soon.