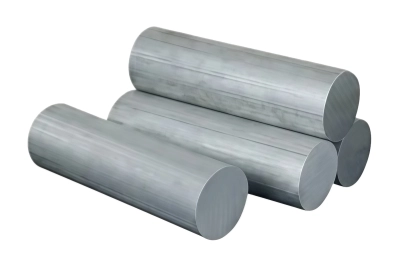

2024 Aluminum Bar

2024 aluminum alloy bar is heat-treatable 2000 series aluminum alloys (Al-Cu-Mg system).They are high-performance aerospace aluminum bars, often referred to as “aerospace alloys.” They possess exceptional strength, excellent machinability, and good surface finish, making them ideal for high-performance and precision components requiring high dimensional accuracy. They are widely used in aircraft structures, truck wheels, medical devices, and other fields.

As a trusted 2024 aluminium bar production factory and supplier, we specialize in providing top-quality AL-2024 aluminum bars tailored to your needs. Experience the difference with our premium products, dedicated and customized service. Contact us for your AL-2024 aluminum rod bar requirements.

HSTF offers 2024 aluminum round bar, 2024 aluminum flat bar, 2024 aluminum square bar and 2024 aluminum hex bar.

Specification

| Product Name | 2024 Aluminum Bar Rod |

| Equivalent Name | AW-AlCu4Mg1, AU4G1, 3.1355, A92024, AlCu4Mg1, AlCuMg2 |

| Temper | 2024-T3, 2024-T4, 2024-T6, 2024-T351, 2024-T851, 2024-T42 |

| Product Type | Cold drawn bar, extruded bar, forged bar, precision drawn bar |

| Stock Shape | Round bar, flat bar, square bar, hexagonal bar |

| Cold Finish Bar Specification |

AMS4120, AMS-QQ-A-225/6 |

| Extruded Bar Specification | AMS4120, ASTM B211, AMS4152, ASTM B221; EN573, EN485; AMS 4339, AMS 4164, AMS 4165; AMS-QQ-A-200/3 |

2024 Aluminum Bar Chemical Composition

| Element | Composition (%) |

| Si | 0~0.5% |

| Fe | 0~0.5% |

| Cu | 3.8~4.9% |

| Mn | 1.2~1.8% |

| Mg | 0.3~0.9% |

| Cr | 0~0.1% |

| Zn | 0~0.25% |

| Ti | 0~0.15% |

| Al | 92~93.5% |

2024 Aluminum Bar Temper Type

To meet diverse performance and processing requirements, HSTF supplies 2024 aluminum bars in a full range of standard tempers. Each temper offers a unique balance of strength, ductility, and machinability, making them suitable for different structural, aerospace, and precision engineering needs.

2024-T3/T3511

Used for high-load, high-precision parts such as aircraft frames, ribs, and fasteners, with operating temperatures below 150°C. The T3511 incorporates stretching and straightening processes to improve dimensional stability and eliminate internal stress.

2024-T351

2024-T351 aluminum undergoes solution heat treatment, stress relief, and natural aging. It is commonly used in aerospace, automotive, machinery, and industrial fields. Suitable for components needing good fatigue resistance and strength.

2024-T851

Suitable for structural components subjected to extreme loads. Commonly used in the aerospace industry, such as commercial and military aircraft, wing tension members, and critical aircraft structures. Also used in automotive and industrial parts.

2024-T4

Compared to other 2024 aluminum alloys, it has the highest ductility; suitable for applications requiring high strength and high elongation. It is widely used in aerospace and military fields, such as in China’s large aircraft, Shenzhou spacecraft, and satellites.

2024-T42

With high strength and toughness, it is ideal for aerospace and automotive parts. It also has excellent machinability and fatigue resistance. It is used to manufacture truck wheels, aircraft wheels, products machined on automatic lathes, and rivets.

2024-T6

2024-T6 aluminum possesses excellent high load-bearing and high-strength properties. It is primarily used in aircraft structures, rivets, truck wheels, propeller components, and other parts; it is also used in the petroleum, chemical, and construction industries.

2024 Aluminum Bar Mechanical Properties

| Temper | T3 | T351 | T851 | T4 | T42 | T6 |

| Density | 0.1 lb/in3 | 0.1 lb/in3 | 0.1 lb/in3 | 0.1 lb/in3 | 0.1 lb/in³ | 0.1 lb/in³ |

| Ultimate Tensile Strength (ksi) | 70 (bare); 65 (clad) | 67 | 75 | 69 | 69 | 73 |

| Yield Tensile Strength (ksi) | 50 (bare); 45 (clad) | 47 | 66 | 45 | 45 | 63 |

| Elongation at Break (%) | 18 | 13 | 4.90 | 16 | 16 | 7 |

| Fatigue Strength (ksi) | 20 | 20 | 17 | 20 | 20 | 18 |

| Hardness Rockwell | Brinell | B75 | 120 | B75 | 120 | B84 | 140 | B75 | 120 | B75 |120 | B82 |135 |

| Modulus of Elasticity (ksi) | 10,600 | 10,000 | 10,000 | 10,000 | 10,000 | 10,600 |

| Machinability (%) | 70 | 70 | 70 | 70 | 70 | 70 |

| Thermal Conductivity (BTU-in/hr-ft^2-°F) | 840 | 840 | 1,050 | 840 | 840 | 1050 |

If you’re unsure which tempering grade is best for your application, our technical team can help you select the appropriate grade and processing conditions. Contact us for expert advice, data sheets, or custom supply options tailored to your project.

2024 Aluminum Bar Producr Type

Our best-selling 2024 aluminum bars offer high strength, excellent fatigue resistance, and reliable machinability. From aerospace structural components to efficient CNC turning, we provide a full range of production types and sizes to meet your critical needs.

Forged 2024 Aluminum Bar

Forged to achieve superior internal structure and mechanical strength, it is ideal for heavy aerospace components such as landing gear, joints, and supports. Large diameter sizes are available.

High Strength & Forged Quality & Large Sizes

Extruded 2024 Aluminum Bar

Cost-effective and versatile, available in round, square, and flat profiles. Commonly used for structural frames, jigs, and medium-precision parts across aerospace, tooling, and machinery industries.

Versatile & Low-Cost & Standard Profiles

Large Diameter 2024 Aluminum Bar

Supplied in diameters up to 1350mm, suitable for large structural parts, aerospace tooling bases, and custom-machined components. Excellent internal quality and high stability under heavy loads.

Ø1350mm Max & Stable Supply & Machinable

2024 T351 Precision Aluminum Round Rod

Preferred for aerospace structural use, offering high fatigue resistance, excellent machining performance, and consistent mechanical properties.

Aerospace Grade & Tight Tolerance & In-Stock Sizes

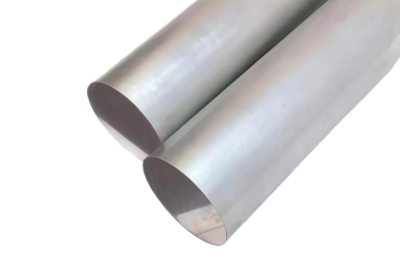

2024 CF Aluminum Rod

2024 Cold Finished Aluminum Bar is a high-performance alloy. The cold rolling process enhances mechanical properties, giving it higher dimensional accuracy, surface finish, and strength.

High Dimensional Accuracy & High Strength & Surface FinishHSTF 2024 Aluminum Bar Stock

2024 Aluminum Round Bar [click view more] |

|||

| Aluminum Alloy 2024 T351 Round Rod *CF – Cold Finished | 1/2 CF | 1-1/2 CF | 3-1/8 CF |

| 5/8 CF | 1-9/16 CF | 3-1/4 CF | |

| 11/16 CF | 1-5/8 CF | 3-3/8 CF | |

| 3/4 CF | 1-3/4 CF | 3-1/2 CF | |

| 13/16 CF | 1-13/16 CF | 3-5/8 CF | |

| Aluminum Alloy 2024 T351 Round Rod *CF – Cold Finished | 7/8 CF | 1-7/8 CF | 3-3/4 CF |

| 15/16 CF | 2 CF | 3-7/8 CF | |

| 1 CF | 2-1/8 CF | 4 CF | |

| 1-1/16 CF | 2-1/4 CF | 4-1/4 CF | |

| 1-1/8 CF | 2-3/8 CF | 4-1/2 CF | |

| Aluminum Alloy 2024 T351 Round *CF – Cold Finished | 1-3/16 CF | 2-1/2 CF | 4-3/4 CF |

| 1-1/4 CF | 2-5/8 CF | 5 CF | |

| 1-5/16 CF | 2-3/4 CF | 6 CF | |

| 1-3/8 CF | 2-7/8 CF | 7 CF | |

| 1-7/16 CF | 3 CF | 8 CF | |

| Aluminum Alloy 2024 T4 Round *CF – Cold Finished | 1/8 CF | 11/32 CF | 17/32 CF |

| 3/16 CF | 3/8 CF | 9/16 CF | |

| 7/32 CF | 13/32 CF | 5/8 CF | |

| 1/4 CF | 7/16 CF | 3/4 CF | |

| 9/32 CF | 15/32 CF | ||

| 5/16 CF | 1/2 CF | ||

| Aluminum Alloy 2024 T851 Round *CF – Cold Finished | 1/2 CF | 1-3/4 CF | 3-1/2 CF |

| 5/8 CF | 2 CF | 3-5/8 CF | |

| 3/4 CF | 2-1/4 CF | 3-3/4 CF | |

| 7/8 CF | 2-1/2 CF | 4 CF | |

| 1 CF | 2-3/4 CF | 4-1/2 CF | |

| 1-1/4 CF | 3 CF | 4-3/4 CF | |

| 1-1/2 CF | 3-1/4 CF | 5 CF | |

2024 Aluminum Square Bar |

|||

| Aluminum Alloy 2024 T4 square *CF – Cold Finished | 1/4 CF | ||

| Aluminum Alloy 2024 T4 square *CF – Cold Finished | 3/8 CF | ||

| Aluminum Alloy 2024 T851 Square *CF – Cold Finished | 1/2 CF | 1 CF | 1-1/2 CF |

| Aluminum Alloy 2024 T851 Square *CF – Cold Finished | 3/4 CF | 1-1/4 CF | 2 CF |

2024 Aluminium Hex Bar |

|||

| Aluminum Alloy 2024 T351 Hexagon *CF – Cold Finished | 1/2 CF | 7/8 CF | 1-5/8 CF |

| Aluminum Alloy 2024 T351 Hexagon *CF – Cold Finished | 9/16 CF | 1 CF | 1-3/4 CF |

| Aluminum Alloy 2024 T351 Hexagon *CF – Cold Finished | 5/8 CF | 1-1/8 CF | 1-7/8 CF |

| Aluminum Alloy 2024 T351 Hexagon *CF – Cold Finished | 11/16 CF | 1-1/4 CF | 2 CF |

| Aluminum Alloy 2024 T351 Hexagon *CF – Cold Finished | 3/4 CF | 1-3/8 CF | 2-1/4 CF |

| Aluminum Alloy 2024 T351 Hexagon *CF – Cold Finished | 13/16 CF | 1-1/2 CF | 2-1/2 CF |

| Aluminum Alloy 2024 T4 Hexagon *CF – Cold Finished | 1/4 CF | ||

| Aluminum Alloy 2024 T4 Hexagon *CF – Cold Finished | 5/16 CF | ||

| Aluminum Alloy 2024 T4 Hexagon *CF – Cold Finished | 3/8 CF | ||

| Aluminum Alloy 2024 T4 Hexagon *CF – Cold Finished | 7/16 CF | ||

| Aluminum Alloy 2024 T851 Hexagon *CF – Cold Finished | 1/2 CF | 7/8 CF | 1-1/2 CF |

| Aluminum Alloy 2024 T851 Hexagon *CF – Cold Finished | 5/8 CF | 1 CF | 1-3/4 CF |

| Aluminum Alloy 2024 T851 Hexagon *CF – Cold Finished | 3/4 CF | 1-1/4 CF | 2 CF |

- Inventory size, quick delivery within 7-10 days.

- We update our inventory frequently. If you cannot find the specification you need, please contact us.

Application

HSTF 2024 aluminium bars are trusted by customers across aerospace, automotive, defense, and precision engineering sectors. With multiple tempers, shapes, and processing methods available, we help clients select the most suitable bar for their application scenario—whether it requires high fatigue strength, excellent machinability, or reliable dimensional control.

Aerospace & Aviation

Used in wing ribs, fuselage frames, landing gear components, and fasteners. We recommend:

- T351 / T851 Round Bar for fatigue-critical structures

- Forged Bar for high-load parts like joints and gear supports

- Chamfered Bar for automated fastener production

Automotive Industry

Heavy-duty gears, shafts, or tooling fixtures, benefiting from its ability to withstand repeated stress and precision machining.

- Extruded Bar provides cost-effective strength

- Precision stripping bars are suitable for suspension components and CNC bushings

Industrial Machinery

- Heavy-duty frames: press bed beams, hydraulic cylinder mounts, and conveyor tension bars.

- Robotic components: arm joint pins, end-effector supports, and precision slide rails.

- Tooling fixtures: die-set alignment bars, clamping blocks, and mold cavity inserts.

Fasteners & Connectors

- Bolts and screws: high-strength bolts and screws used in aerospace, automotive, and industrial equipment.

- Nuts and washers: used to provide secure connections and fastening.

- Rivets: used for permanent connections in aircraft and other structures.

Defense & Military

In these applications, durability and lightweight are crucial.

- Armored vehicle parts: hull reinforcement bars, turret ring supports, and weapon cradle brackets.

- Aircraft ordnance: bomb rack fittings, missile launcher guides, and ejection seat rails.

- Communication systems: antenna mast segments, radar base supports, and field equipment frames.

Sports Equipment

High strength, lightweight and good fatigue performance meet the stringent requirements of sports equipment for material properties.

- Bicycle frames and components: Aluminum frames are approximately 30% lighter than steel frames.

- Golf clubs: Primarily used in the clubhead.

- Hiking poles and ski poles: Reduce weight and enhance equipment durability for outdoor enthusiasts.

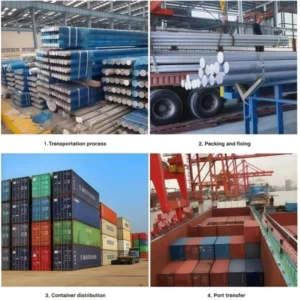

Packaging

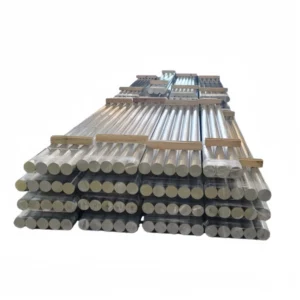

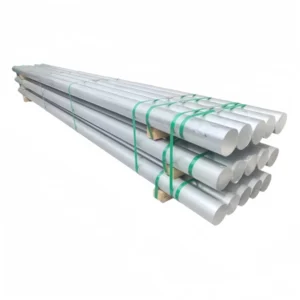

- Inner protection: Each aluminum rod is wrapped in PE film, with optional paper, cardboard, or foam layers formoisture and scratch resistance.

- Bundle securing: Aluminum rods are bundled and reinforced with steel or PET straps, with protective padding toprevent loosening and abrasion.

- Outer packaging: Bulk orders are packed in sturdy wooden crates or pallets, with optional export-gradefumigation and moisture-proof lining for compression and shock resistance.

Why Choose Us?

Quality Assurance – All products comply with ASTM, ISO, RoHS and other international standards, ensuring high purity, uniformstructure, and stable performance.

Professional Supplier – Professional 2024 aluminum rod bar supplier in China. We have an advanced factory to ensure quality and efficiency.

Competitive Price – The mature supply chain system, advanced equipment and technology ensure that our products are highly competitive in cost and price.

Superior Quality – Quality supervision on whole process of production from raw materials, manufacturing, packaging, warehousing till container loading.

On-Time Delivery – The mature logistics management system and company self owned freight forwarder ensure that our OTD rate reaches 100%.

FQA

Yes,we promise to provide best quality products and delivery on time .Honesty is our company’s tenet.

We can provide the sample for customer with free, but the customer account will cover the courier freight.

The manufacturing process produces each piece in certified workshops. Our inspection team checks them piece by piece. This is done according to national QA/QC standards. We also could issue the warranty to customer to guarantee the quality.

We specialize in steel business for years. Our headquarters is in Liaocheng Economic Zone. This is in Shandong province. You are welcome to investigate in any way. By all means, you could place an order. Use trade assurance for your payment security.

Our team will check email and fax within 24 hours. Meanwhile, these platforms remain online 24 hours. They include Facebook, Skype, WeChat, and WhatsApp. Please send us your requirements and order information. Provide the specification details. These include steel grade, size, and quantity. Also include the destination port. We will work out the best price soon.