2017 Aluminum Bar

2017 aluminum rod bar is a high-strength, heat-treatable aluminum-copper alloy designed for structural and precision-machined parts. It delivers greater tensile strength than common 6xxx series alloys like 6061, while offering better machinability than higher-end grades such as 2024—making it ideal for aircraft fittings, automotive components, and industrial arms.

We offers 2017 aluminum rod in tempers including T3, T4, T6, and T8, with customizable diameters, fixed-length cutting, and surface treatments like polishing or anodizing. Backed by stable inventory and strict quality control, we provide reliable supply for both domestic and international machining applications.

-

- High Strength-to-Weight Ratio– Excellent mechanical properties with low density.

- Superior Machinability– Enables high-speed machining with excellent surface finish.

- Good Fatigue Resistance– Suitable for dynamic load applications.

- Heat-Treatable– Can be optimized for specific strength requirements.

- Dimensional Stability– Maintains precision in machined components.

- Weldable with Proper Techniques– Can be joined for complex assemblies.

- Proven Reliability– Extensive track record in aerospace applications.

HSTF Aluminum is a high-quality 2017 aluminum rod bar supplier and manufacturer in China. We have large stock, factory direct price, quality assurance, fast delivery.

Specification

| Alloy | 2017 Aluminum Alloy |

| Tempers Offered | T3, T4, T451, T6, T8 |

| Diameter Range | 3mm to 300mm (customizable upon request) |

| Length | standard 6 meters; fixed-length cutting available |

| Available Shapes | Round/Hex/Square/Flat/Custom extruded profiles |

| Surface Finishes | bright finish, sandblasted, anodized, deburred cut surfaces |

| Additional Services | precision cutting; OEM marking and custom packaging; surface and structural processing upon request |

| Specifications | ASTM B221, ASTM B211, ASTM B316, AMS 4118, AMS-QQ-A-225/5, AMS QQ-A-200/9, UNS A92017, EN573, EN485, JIS H4040 or customer-specified standards |

| Packaging | 1. Inner protection: We wrap each aluminum rod in PE film to resist moisture and scratches.

2. Bundle securing: Aluminum rods are bundled and reinforced with steel or PET straps, with protective padding toprevent loosening and abrasion. 3. Outer packaging: Bulk orders are packed in sturdy wooden crates or pallets, with optional export-gradefumigation and moisture-proof lining for compression and shock resistance. |

2017 Aluminum Bar Physical Properties

| Element | Content Range (%) |

| Copper (Cu) | 5.5 – 6.5 |

| Magnesium (Mg) | 0.2 – 0.8 |

| Manganese (Mn) | 0.4 – 1.0 |

| Iron (Fe) | ≤ 0.7 |

| Silicon (Si) | ≤ 0.2 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Aluminum (Al) | Balance (remainder) |

HSTF 2017 Aluminum Bar Type

2017 Aluminum Round Bar

Diameter: 3-600mm

Length: 1-12m

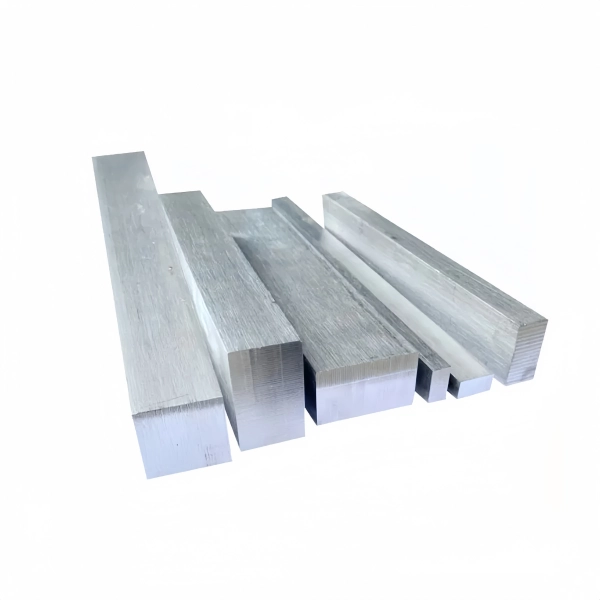

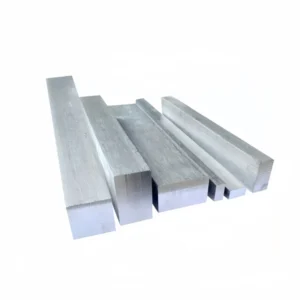

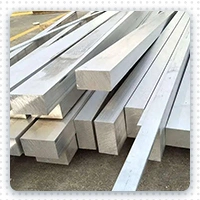

2017 Aluminum Square Bar

Side Length: 4-100mm

Bar Length: can be cut

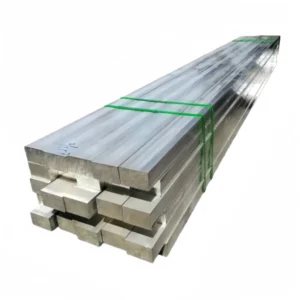

2017 Aluminum Flat Bar

Diameter: 30-100mm

Length: can be cut

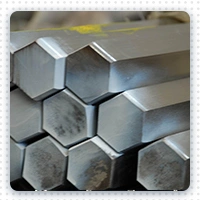

2017 Aluminum Hex Bar

Size: 4-100mm A/F

Length: can be cut

2017 T6 Aluminum Bar

High strength, hardness, and corrosion resistance, commonly used in structural components, aerospace manufacturing, and high-pressure vessels.

2017 T4 T451 Aluminum Bar

The 2017 T4 offers high strength with excellent machinability, while 2017 T451 provides outstanding strength and hardness for applications requiring corrosion resistance.

2017 T3 Aluminum Bar

Moderate strength and excellent workability, ideal for rivets, aircraft fittings, and lightly stressed components.

2017 Cold Drawn Aluminum Bar

Excellent surface finish and dimensional accuracy, suitable for precision machining and high-end product manufacturing.

2017 Extruded Aluminum Bar

Good surface quality and uniform mechanical properties, commonly used in construction, transportation, and electronics industries.

2017 Anodized Aluminum Bar

Enhanced surface protection and appearance, suitable for decorative or corrosion-sensitive applications.

2017 Aluminum Rod Mechanical Properties |

||||

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

| T3 | 320 – 360 | 215 – 250 | 12 – 18 | 90 – 110 |

| T4 | 340 – 380 | 230 – 270 | 10 – 15 | 95 – 115 |

| T6 | 400 – 440 | 340 – 380 | 8 – 12 | 115 – 135 |

| T8 | 430 – 470 | 380 – 410 | 6 – 10 | 130 – 145 |

| CF (Cold Finished) | 360 – 400 | 270 – 320 | 10 – 14 | 105 – 120 |

|

||||

Hot Selling 2017 Aluminum Round Bar Size |

||

| Product | Metric Diameter Inventory mm | Inch Diameter Inventory (inch) |

| 2017-T4 | φ30 | 1 1/6 |

| 2017-T4 | φ40 | 1 1/2 |

| 2017-T4 | φ50 | 2 |

| 2017-T4 | φ60 | 2 3/8 |

| 2017-T4 | φ70 | 2 3/4 |

| 2017-T4 | φ80 | 3 1/8 |

| 2017-T4 | φ90 | 3 1/2 |

| 2017-T4 | φ100 | 4 |

| 2017-T4 | φ110 | 4 1/3 |

| 2017-T4 | φ120 | 4 3/4 |

| 2017-T4 | φ130 | 5 1/8 |

| 2017-T4 | φ140 | 5 1/2 |

| 2017-T4 | φ150 | 5 7/8 |

| 2017-T4 | φ160 | 6 1/4 |

| 2017A-T6 | φ43 | 1 11/16 |

Our inventory is frequently updated. If the sizes listed above do not meet your specifications, you can contact us directly for the latest inventory specifications or to arrange for customization.

Contact Us NowApplication

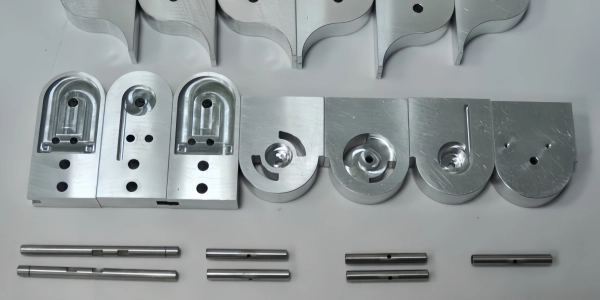

Precision Machined Parts

This is the primary application. Its free-machining characteristics make it ideal for producing:

- Aerospace Components:Aircraft fittings, gears, bolts, and other internal structural parts that require a high strength-to-weight ratio.

- Automotive Components:Precision parts like pistons, cylinder heads, and other engine and drivetrain components.

- Screws, Bolts, and Rivets:Especially for high-strength fasteners used in structural applications.

General Manufacturing and Tools

provides an excellent combination of light weight, good machinability, and adequate strength, making it ideal for versatile general manufacturing and tooling applications.

- Shafts and pins: lightweight bars used in machinery drives and indexing mechanisms where reduced weight improves efficiency and ease of handling.

- Jigs and fixtures: durable, easily machined bars form precise locating and clamping devices that speed up setup and enhance repeatability in production.

Why Choose Us?

Quality Assurance – All products comply with ASTM, AMS, EN, ISO and other international standards, ensuring high purity, uniformstructure, and stable performance.

Professional Supplier – Professional 2017 aluminum bar supplier in China. We have an advanced factory to ensure quality and efficiency.

Competitive Price – The mature supply chain system, advanced equipment and technology ensure that our products are highly competitive in cost and price.

Superior Quality – Quality supervision on whole process of production from raw materials, manufacturing, packaging, warehousing till container loading.

On-Time Delivery – The mature logistics management system and company self owned freight forwarder ensure that our OTD rate reaches 100%.