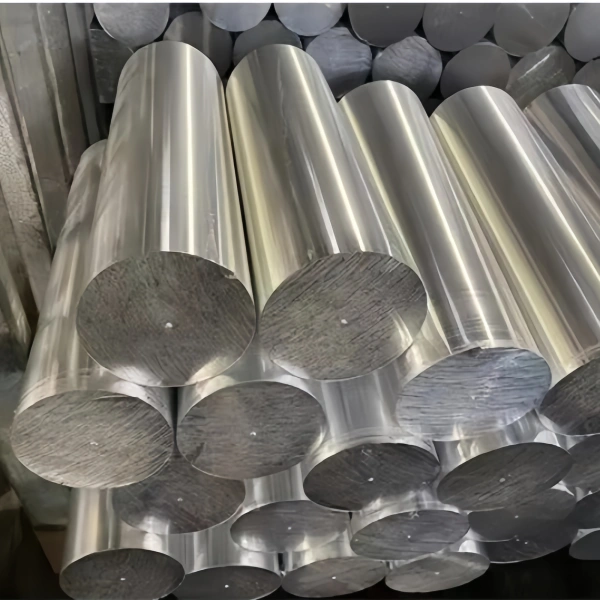

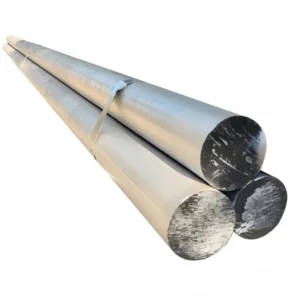

2011 Aluminum Round Bar

2011 Aluminum Round Bar is a high-performance free-machining aluminum alloyfrom the 2000 series, specifically engineered for applications requiring exceptional machinability, superior surface finish, and high production efficiency. This heat-treatable copper-based alloycontains 5.0–6.0% copperwith additions of lead (0.2–0.6%) and bismuth (0.2–0.6%), which significantly enhance its machining characteristics by promoting chip breakability and reducing tool wear.

The industry widely recognizes 2011 aluminum as one of the most machinable aluminum alloys available, achieving machining speeds comparable to brass while maintaining aluminum’s lightweight advantages.

-

- One of the most commonly used aluminum alloys for free-cutting, producing easily removable fine chips during high-speed machining.

- Exhibits excellent machining characteristics, capable of producing complex and fine parts, widely used in the manufacturing of components requiring extensive machining.

- Relatively poor corrosion resistance; HSTF can provide anodizing treatment to offer additional surface protection.

- Manufacturers can extrude, draw, or forge 2011 aluminum round bar into rods, tubes, or other shapes, serving various purposes.

- Suitable for multiple engineering fields due to its corrosion resistance, lightweight, and high strength, such as aerospace, chemical engineering, and construction machinery manufacturing.

HSTF Aluminum is a high-quality 2011 aluminum rod bar supplier and manufacturer in China. We have large stock, factory direct price, quality assurance, fast delivery.

Specification

| Products Name | 2011 Aluminum Round Bar |

| Tempers | T3, T6, T8 |

| Standard Diameter | 3mm to 300mm (customizable) |

| Length | Standard 6 meters, custom cut-to-length available |

| Specification | AMS-QQ-A-225/3 ASTM B211 UNS A92011 and RoHS environmental directive requirements to ensure product quality is stable and environmentally compliant. |

| Surface Treatments | Bright finish, sandblasting, anodizing, deburring of cut edges, and more |

| Additional Services | Custom cut-to-length, OEM marking, custom packaging, and special processing services |

| Packaging | 1. Inner protection: We wrap each aluminum rod in PE film to resist moisture and scratches.

2. Bundle securing: Aluminum rods are bundled and reinforced with steel or PET straps, with protective padding toprevent loosening and abrasion. 3. Outer packaging: Workers pack bulk orders in sturdy wooden crates or pallets, with options for export-grade fumigation and moisture-proof linings to protect against compression and shock. |

2011 Aluminum Chemical Composition

| Element | Content Range |

| Silicon (Si) | 0.4% |

| Iron (Fe) | 0.7% |

| Copper (Cu) | 5%-6% |

| Lead (Pb) | 0.2%-0.6% |

| Bismuth (Bi) | 0.2%-0.6% |

| Zinc (Zn) | 0.3% |

2011 Aluminum Round Bar Tempers

| Temper Type | Description |

|

T3 |

2011 T3 aluminum alloy undergoes solution heat treatment first, where it is heated to a high temperature and then rapidly cooled, allowing alloy elements to dissolve into the aluminum matrix. Manufacturers then further strengthen it through cold working to enhance hardness and strength. Finally, manufacturers carry out natural aging by leaving the material at room temperature for a period of time, allowing precipitates within the material to refine and improve mechanical properties. T3 temper aluminum alloys are suitable for applications requiring moderate strength and good machinability. |

| T6 | 2011 T6 aluminum alloy is first subjected to solution heat treatment, where it is heated to a high temperature and quickly cooled to ensure the alloy elements are fully dissolved. Then, we carry out artificial aging by heating the material to a specified temperature and holding it for a period of time, allowing the precipitates to refine and significantly increase strength. T6 temper aluminum alloys exhibit high strength and hardness, making them suitable for applications that require the handling of large loads and high strength. |

|

T8 |

2011 T8 aluminum alloy undergoes multiple steps including solution heat treatment, cold working, and artificial aging. First, the aluminum alloy is subjected to solution heat treatment, where it is heated to a high temperature and rapidly cooled to dissolve the alloy elements. Then, cold working further increases the material’s strength. Operators heat the aluminum alloy to a specified temperature. They hold it under controlled conditions for a period. This occurs during the artificial aging process. This allows the precipitates to refine. It also maximizes the strength. The T8 temper results in the alloy achieving its best strength. It also achieves its best hardness. This makes it ideal for high-precision applications. These applications require high strength and good machinability. |

HSTF Hot Selling Size

| Diameter (inch) | Diameter (mm) |

| 1 | 25.4 |

| 1 1/2 | 38.1 |

| 1 1/4 | 31.75 |

| 1 1/8 | 28.575 |

| 1 3/4 | 44.45 |

| 1 3/8 | 34.925 |

| 1 5/8 | 41.275 |

| 1 7/8 | 47.625 |

| 1/2 | 12.7 |

| 1/4 | 6.35 |

| 1/8 | 3.175 |

| 2 | 50.8 |

| 2 1/2 | 63.5 |

| 2 1/4 | 57.15 |

| 2 3/4 | 69.85 |

| 3 | 76.2 |

| 3/4 | 19.05 |

| 3/8 | 9.525 |

| 5/8 | 15.875 |

| 7/8 | 22.225 |

We frequently update our inventory. If the sizes listed above do not meet your specifications, you can contact us directly for the latest inventory specifications or to arrange for customization.

Contact Us NowApplication

| Application Area | Applied Parts | Detailed Description |

Automotive |

Fuel injectors, pump housings, speedometer assemblies | 2011 aluminum round bars are widely used in the automotive industry for parts such as fuel injectors, pump housings, and speedometer assemblies. These components require high precision and durability. 2011 aluminum alloy, with its good machinability and moderate strength, provides the necessary mechanical properties. Particularly in applications such as fuel injectors and pump housings, precise dimensions and wear resistance are crucial. 2011 aluminum alloy ensures stability during long-term use. |

Electronics |

TV housings, camera frames, watch parts | 2011 aluminum round bars are widely used in the electronics industry for parts like TV housings, camera frames, and watch parts. Due to its lightweight and machinability, aluminum alloy is ideal for manufacturing precision electronic product enclosures. These parts require both durability and an aesthetically pleasing appearance. They also need high precision. 2011 aluminum alloy improves corrosion resistance through surface treatment. This ensures product quality and stability during long-term use. |

Machinery |

Screw machine parts, industrial connectors, precision gears | 2011 aluminum round bars are used in the machinery industry to manufacture parts like screw machine parts, industrial connectors, and precision gears. Due to its excellent machinability, manufacturers can precisely process 2011 aluminum alloy into complex shapes to meet various industrial requirements. These components typically require high wear resistance and durability. 2011 aluminum alloy effectively ensures the efficient operation of machinery. It also provides long-term stability. |

Aerospace/Marine |

Lightweight structural components (such as airframe frames, ship hulls, etc.) | 2011 aluminum round bars are primarily used in aerospace and marine industries for lightweight structural components requiring a high strength-to-weight ratio. These components require materials that offer both high strength and low weight. This improves the performance and fuel efficiency of aircraft and ships. Due to 2011 aluminum alloy’s lower density and good mechanical properties, it is an ideal choice for such high-performance applications. Manufacturers widely use it in the manufacturing of aerospace and marine structural parts. |

Why Choose Us?

Quality Assurance – All products comply with ASTM, AMS, EN, ISO and other international standards, ensuring high purity, uniformstructure, and stable performance.

Professional Supplier – Professional 2011 aluminum bar supplier in China. We have an advanced factory to ensure quality and efficiency.

Competitive Price – The mature supply chain system, advanced equipment and technology ensure that our products are highly competitive in cost and price.

Superior Quality – Quality supervision on whole process of production from raw materials, manufacturing, packaging, warehousing till container loading.

On-Time Delivery – The mature logistics management system and company self owned freight forwarder ensure that our OTD rate reaches 100%.